| Author |

Message |

Thorn48sw

| | Posted on Friday, October 10, 2014 - 03:51 pm: |

|

Hey guys, just got my Buell Ulysses and am loving it. The previous owner let it sit for a few years and when I bought it told me he had thought there was a stator issue but the dealer said it was battery and couldn't replicate. He did not have the problem after that. I got it home no problems, changed the oil and primary and have been really loving it. First impression is it runs really smooth but gets extremely hot in the saddle, so much so I cannot wear shorts while riding (atgatt I guess).

A few days ago I got it out on the highway and while accelerating around 75 I had the engine cut out and light came on for a few seconds then back to normal. It did this twice, so I headed home and everything seemed okay. No blinking lights. Figured it was old fuel in the bottom of the tank. Texted the previous owner and he said those were the same symptoms that made him suspect the stator but the dealer mechanic didn't find anything.

Today, I had it do the same thing at 4k rpms but a lower speed. Then in a parking lot as I was coming to a stop the engine died and I left it off. Let it cool and went into a store and it started right back up and got me home 10 minutes later.

I am trying to decide, do I take it to the dealer or attempt to troubleshoot it myself. Doing research I'm finding there are a lot of possible reasons for this. Should I drive it there or tow it? I commute on my bike and am selling my KLR 650 this weekend to fund my Ulysses and am afraid of a long dealer stay.

Engine overheating? Electrical issue? Is it the stator? I have no idea where to start.

Any advice? Thanks in advance. |

Hootowl

| | Posted on Friday, October 10, 2014 - 04:06 pm: |

|

Sure sounds electrical, but it doesn't sound like a bad stator to me. Have you read your fault codes? |

Thorn48sw

| | Posted on Friday, October 10, 2014 - 04:22 pm: |

|

I haven't gotten to check the codes yet but since the problem was happening before and the dealer couldn't come up with anything I'm kind of thinking there may not be codes registering? As I said, totally new to the bike and Buell and trying to decide the best course of action. Should I get the cable and run the diagnostics myself? |

Hootowl

| | Posted on Friday, October 10, 2014 - 04:35 pm: |

|

I would. ECMSpy is pretty handy.

Missing when it gets hot could be a bad coil. I'm not sure that would cause the check engine light to come on though. I don't have a Uly, but from what I understand, the seat can rub on the ECM and cause issues. Has that been addressed? |

Reepicheep

| | Posted on Friday, October 10, 2014 - 04:48 pm: |

|

If you can turn a wrench without making things worse when you are done than they were when you started (some people can't, no shame in knowing what you aren't good at) I'd definitely do it yourself. The mechanic won't have any advantage over you for this problem, and you don't pay you $90 an hour.

First, it's an air cooled 1200 CC VTwin. It's not a "shorts" bike. So even if you aren't ATGATT, you should be Most of the Gear All of the Time. If it is an earlier Uly (2006/2007) and it doesn't have the "comfort kit", that will help, but it will still fry your leg in shorts (and even get pretty toasty in jeans).

And your symptoms aren't bad stator symptoms, so you can cross that off your list also.

So on to your problem...

There are two common and one less common problems that could account for what you are experiencing. From most common to least common, the problems to look for are:

1) ECM wire bundle getting pressure from seat, which puts pressure on ECM connector, which cracks the solder joints on the ECM main board. To diagnose, idle the bike with the seat off and wiggle the ECM connections six ways to sunday and see if you can make it stall. If so, you found your problem. To fix it, dissect the ECM near the connector (pictures on this site) and resolder the connectors. Get the pressure off those connectors regardless (some relocate, some people bend and pad the ECM, lots of discussion on the board we can scare up for you).

2) The wires going down through the flyscreen and bending across the frame to go in under the steering head crack internally. Sometimes at the "ground splice" in that bundle, sometimes the conductor on some random wire cracks internally (the insulation will look OK). So pull apart the triple splice thing and solder, crimp, or screw terminal to reinforce it, and pull apart the bundle and run each wire through your fingers with a slight bend to the wire feeling for that internal conductor being broken or nearly broken. If you find one, cut, strip, and solder in a splice to extend and repair it, and heat shrink tube it to insulate it, and put the bundle back together and wrap it up.

3) (Less common, but it happens). The Cam Position Sensor can fail, which will stop sending signals to the ECM that the motor is turning, and it won't spark the plugs anymore. This typically manifests like somebody hit the kill switch for a second, and when it comes back on power you get some awful backfire. The tach needle could do the funky chicken while that happens, it is usually worse on a hot engine, and after it starts it will quickly get worse until it fails completely (like maybe 1 hour of riding from first symptom to totally unstartable). Harder to diagnose, if you have access to an oscilloscope its easy to check. If you do just want to buy a new sensor and put it in, if it doesn't solve the problem, you then have a spare sensor to keep with you on the bike as a hot spare in the event it does fail in the future.

Start with those, we can dig in more from there. |

Hootowl

| | Posted on Friday, October 10, 2014 - 04:54 pm: |

|

Great post Bill. |

Thorn48sw

| | Posted on Friday, October 10, 2014 - 05:10 pm: |

|

Wow, this is great info. Thanks so much to both of you. I will begin diagnosing this weekend and will update with what I find. |

Thorn48sw

| | Posted on Friday, October 10, 2014 - 05:29 pm: |

|

You guys are awesome. Wiggling the ECM I was able to replicate the problem twice. I am really excited that I have something to go after and its not too major. I guess since its just electrical if I'm careful on it its okay for me to keep riding the bike as I'm working on fixing it? Like I said this is my primary transportation. I'll begin scouring the site for guides to resolder and relocate the ecm. Thanks again! |

Court

| | Posted on Friday, October 10, 2014 - 05:40 pm: |

|

>>>>You guys are awesome.

And cheap !

How would you like to have been handing someone $180 tonight and when you asked them what they'd done . . . "wiggled some wires".

We . . . at Badweb. . . don't let anyone beat our prices!

:-) |

Daddio

| | Posted on Friday, October 10, 2014 - 07:04 pm: |

|

...and that's IF you could find a dealer tech who would deign themselves low enough to even remove the seat on a Uly.

Thorn, if, like Reepi says, you can turn a wrench, keep your $$ in your pocket, except when you find a factory service manual. There's a wealth of knowledge in the book, and even more here on the BadWeb.

Oh, and for future reference, when asking for diagnostic help, it helps us if you put the year of the bike in the post. Later Ulys don't, for example, use a cam position sensor. |

Buellistic

| | Posted on Friday, October 10, 2014 - 07:30 pm: |

|

Get your self the FACTORY SERVICE MANUAL and "PARTS BOOK" from Al at:

www.AmericanSportBike.com ...

Read the DIAGNOSTIC FLOW CHARTS and related TROUBLE SHOOTING INFORMATION ...

Learn to be your own MECHANIC ... |

Reepicheep

| | Posted on Friday, October 10, 2014 - 09:30 pm: |

|

Good news!

Look at this thread for more info...

http://www.badweatherbikers.com/buell/messages/142 838/747295.html |

Thorn48sw

| | Posted on Saturday, October 11, 2014 - 12:59 am: |

|

Hey guys, thanks again for all the help. I went to pull my ecm and while I was idling the bike noticed a really high frequency noise coming from the battery area or ecm (can't tell which definitively). Does this sound like an internal ecm problem or a short somewhere? I will try to pick up the manual soon. Looking forward to some soldering and hopefully getting back on the road. Oh, and my bike is an 06 with 25k on it. |

Buellistic

| | Posted on Saturday, October 11, 2014 - 08:32 am: |

|

The ECM(also stator/voltage regulator) is just like your brain, PUT IN A HOT SPOT SITUATION AND IT WILL GET "HEAT STROKE" ...

This happen early on with car ECM's in a hot spot in the engine compartment ... |

Reepicheep

| | Posted on Saturday, October 11, 2014 - 09:40 am: |

|

There is a fan down there, you sure it wasn't that just doing what it does?

It can also whine if the primary chain is too tight. |

Buellistic

| | Posted on Saturday, October 11, 2014 - 10:37 am: |

|

PRIMARY CHAIN ADJUSTMENT Class 101, just PM me for a copy ...

A TOO TIGHT primary chain generates a lot of heat which kills the STATOR and VOLTAGE REGULATOR ...

Take a "HINT" from the FAN, if the fan blows on it gets TOO HOT there, so move it to a COOLER SPOT !!! |

Thorn48sw

| | Posted on Monday, October 20, 2014 - 10:40 pm: |

|

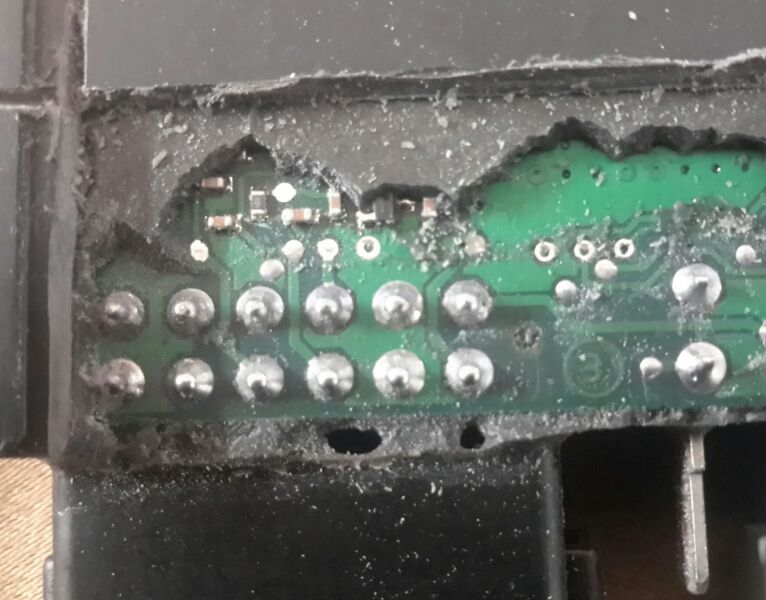

Hey Guys. Adjusted the primary chain and am still hearing the noise. Guess maybe its the fan. Relocated the ECM and still having the issue. Opened it up to see the solder joints and they all look good. I've had the issue happen a lot in the past week, usually once or twice per ride. Never more than a split second and at a number of different speeds and rpms. Got the cable and its not throwing any codes as it does it. Any other ideas? I've attached the photos of the solder joints just in case I missed something. Thanks guys!

|

Reepicheep

| | Posted on Tuesday, October 21, 2014 - 08:25 am: |

|

If you are that far in, and you know how to sling a soldering iron, I'd resolder each of those big connector joints anyway.

It will take a decent power iron given those terminals are bigger metal posts.

The cracks can be REALLY hard to see. You can fix them all faster than you could find one bad one.

If you don't know how to solder, this might not be the first thing you want to learn on though. It's not rocket science, but most people will do it wrong for a bit before they do it right. |

Gabby_duck

| | Posted on Tuesday, October 21, 2014 - 07:31 pm: |

|

My 06 had a similar problem.The 86A,86B page B-17 2006 uly maintenance manual (fuel pump harness connector) had an over crimp pin that caused intermittent open.Found by performing wiggle test. A known problem with the 06 was fuel pump wire chafing inside the fuel tank. |

Gabby_duck

| | Posted on Tuesday, October 21, 2014 - 07:43 pm: |

|

http://badweatherbikers.com/buell/messages/142838/ 370305.html |

Thorn48sw

| | Posted on Friday, October 24, 2014 - 02:16 pm: |

|

Well, it looks like re-soldering was the ticket. I was not confident of doing a good job on my own so I paid a guy to do it for me. As soon as he was the welds he said it was a bad job and so far I've been trouble free for a hundred miles. I have some insulating tape over it right now, any advice on how I should seal it back up? I have the seat cutout and protective post on mine, do you think the relocation is necessary? Excited to be confidently back on the road and am looking forward to a long road trip in the near future. I got the service manual. Now on to fixing the pulsing front rotor. I'm going to try to clean it up and switch to the gold pads. Thanks again everyone for your help! |

Reepicheep

| | Posted on Friday, October 24, 2014 - 03:11 pm: |

|

Got a hot-melt glue gun?

Silicone II (not normal silicone) would also work. |

|

Troubleshooting (Poor Starting/Running/Handling/Ride Issues) »

Archive through February 05, 2015 »

06 XB12X Engine light shutdown

Troubleshooting (Poor Starting/Running/Handling/Ride Issues) »

Archive through February 05, 2015 »

06 XB12X Engine light shutdown

Troubleshooting (Poor Starting/Running/Handling/Ride Issues) »

Archive through February 05, 2015 »

06 XB12X Engine light shutdown

Troubleshooting (Poor Starting/Running/Handling/Ride Issues) »

Archive through February 05, 2015 »

06 XB12X Engine light shutdown