| Author | Message | ||

Henrik |

Has anyone tried the X1 style shifter on an S2. I'm looking to get rid of the big "Arc" style shifter. Henrik | ||

Dave |

I installed the 2001-2003 tuber shifter on my S2. DAve | ||

S2pengy |

Put one my S2. Had to play with the rod lenght and the lever lenght note that shifter pressure will increase but will be more exact. Left the one on my S2t alone. Each has +&-..... | ||

Henrik |

Great. Thanks guys - yet another call to DaveS  Henrik | ||

Bluzm2 |

Thanks for the question Henrik, I was thinking of doing the same thing. I'm heading t5 the bering store tomorrow with my M2 new style shifter parts in hand. I want to see if I can get a sealed needle bearing to replace the plastic bushing. Probably require a bit of machining but it will be worth it. Brad | ||

Henrik |

Ok, so I found this on the Buell site: http://www.buell.com/en_us/gear/accessories/Product.asp?Menu_ID=2&ProductLineID= 5&CategoryID=7&ProductID=1316 That was kinda what I had in mind, except that the shifter is too long - the toe peg to far to the rear. I'd say by at least half a derby cover width. Are the "standard" 2001 - 03 shifters arranged differently? Pictures anyone  Henrik | ||

Jackbequick |

Bluzm2, American Sport Bike sells sets of nicely made bronze bushings that will replace the originals and take most of the play out of the brake and shifter pivots. American Sport Bike is on the sponsor's page. Jack | ||

Davefl |

Henrik, the one in the pic is an X1. The M2/S3 shifter arm is a little shorter. | ||

Bluzm2 |

Jack, The bronze busshings work OK, I had them on my stock 00 shifter. I should have kept them when I switched to the new version shifter. They were much better then stock but I want even better. If I get this figured out, I'll give Al a call. Maybe he can put together a "kit" to make it easier for everyone. Henrik, I'll take a shot of my M2 for you.. They are a bit shorter. Brad | ||

Bluzm2 |

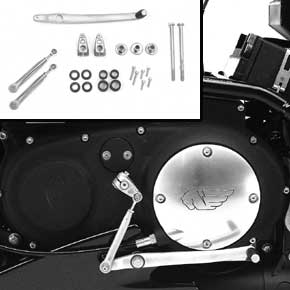

Henrik, I had a few minutes just now. Here's the M2 version. Brad  | ||

Bluzm2 |

Here's the one from the X1:  | ||

Henrik |

Dave, Brad; Thanks much for the information and pictures. Looks like it'll work great. The Banke shifter I had on the S3 had a ball bearing, but it still felt a bit sloppy to me. Brad, do you think needle bearings will give a bit more support against side-to-side rocking? Henrik | ||

Bluzm2 |

Henrik, That's what I'm hoping. I'll know more tomorrow. Brad | ||

Jackbequick |

I put that same M2 setup in Brad's photos on my M2 and, with new nylon bushings, it was a major improvement on the up and over shifter. Here are some typical stocked needle roller bearings: http://tinyurl.com/epdyo Because there are no rotating forces and only partial and intermittant rotation, a needle bearing should work well here with little clearance (i.e., no slop). In use, the load would be shared over the length of several of the needle rollers so it should do much better than a ball bearing. And be much more compact of course. Sounds like a good concept to me. I'd think the real issue on fitting them is going to be the extra diameter needed on the shift lever in the area of the pivot to accomodate the larger diameter of the roller bearing. It makes me wish I still had a milling machine, we could quickly bang out a prototype from a stick of T6 aluminum square or rectangular stock. The M2 has that stepped cylindrical spacer/mount piece that slides over the mounting bolt. If O.D. of the bearing that fits that is too large for the existing levers, maybe the spacer part can be attached to the bolt (grub screws? welded?). Then you could eliminate the outer step to use a bearing with a smaller I.D. and O.D. Jack (Message edited by jackbequick on July 27, 2006) | ||

Bluzm2 |

Sorry guys, I didn't make it to the bearing supply yesterday. I was fabricating my new wheel balancing stand and had my mig welder head south. That suck big time. It's not that old and hasn't been used all THAT much. I can't get enough current out of it to weld 1/16" tubing! It's a Solar, made by Century Manufacturing. Unfortunately, Century was bought out by another company. That company sold all the welding products to Lincoln. Lincoln now owns all of it including Marquette. I tried to contact Lincoln regarding parts but was uncuccessful. I'll try again Monday. I'll try to do the bearing thing sometime this week. Jack, I was thinking I'm going to have to turn down the outside diameter of the stock mounting post. Maybe even have to ream out the shift lever. Not much stock to remove there but ther is a little. Brad | ||

Bomber |

and what little stock is kinda brittle -- trust me ;-} |