| Author | Message | ||

Silas_clone |

I am so happy that my belt is "scary loose", the thing really does shift better! anyway, i used factory method to align rear axle and as a typical old lady, i now feel a slight pull to left, very slight but when riding no hands, i must lean my body over to the right to go straight. anyway, my plan is to move the left axle adjuster back 1/2 turn, figuring my rear wheel is biased to the right...is this correct? Does right bias produce left drift? I understand front wheel counter-steer, but rear wheel input has me confused... this is not a big deal, i will monkey around today and try to adjust the axle a couple different ways, i am just exercising my mind. | ||

Ara |

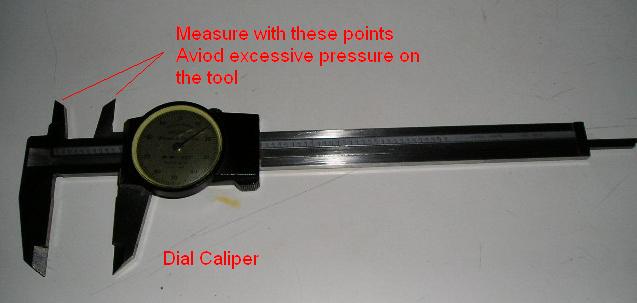

Silas, I've had real good results with a low cost dial micrometer that I purchased at Auto Zone. With care you can get your rear wheel so perfectly adjusted that the steering is completely neutral and you don't even need your knees to nudge her in a hand-off test. It's a modest investment that will take all the guesswork out of aligning your rear wheel. | ||

Bruce_bueller |

If you have stock axle adjusters you can measure the distance from the swingarm. They should both be equal. Or old skool it and count the threads. Thanx DAve. (Message edited by bruce_bueller on August 28, 2005) | ||

Silas_clone |

Fella's I have a dial caliper [nice one, too], that's what I used according to spec. I think that I would use a telescoping feeler gauge. I'll eventually look at swingarm to axle. I'll get it straight, but that's not the question. I was just wondering which way the wheel would be biased on left pull? [ever so slight] It got me thinking. Heck, it could be the way I'm sitting on it or even the road surface. Sitting and thinking, it would seem like even dead straight might actually lead to a pull, kinda like tuning. Do tuners on race bikes "adjust in" a bias, you know, like trim tabs on airplanes?  | ||

Henrik |

Silas, don't know about which way it'd pull, but your idea of using the telescoping feeler gauge to measure the axle to swingarm distance is spot on. About the pulling; there was an article in MCN where they used a newfangled laser gadget to align the rear wheel on an HD Bagger that would pull. After "perfect" alignment it would pull worse  So I guess there's something to your idea of "tuning" wheel tracking. Henrik | ||

Koz5150 |

I use a tape measure and it has worked perfect everytime. | ||

Silas_clone |

Henrik, there has to be enough variance in all the "joints" [engine, frame, front end, steering head bearings, swingarm] connected together between the front and rear axle [consider possible variations when welding and machining surfaces] and the forks. frame and swingarm seem to be so "robust" so there is probably very little "self centering" going on. Add the tires, which may have some sort of "pull" with either tread or carcass and there you have it. Airplanes with propellers have to deal with the fact that the prop becomes a gyro, adding input to trim called precession [sp]. I would imagine that heavy cast motorcycle wheels and flywheels spinning may have some sort of similar input[???] [Just woke up from a pretty good afternoon party...so i feel especially smart tonite] Anyway, the laser alignment story is not surprising. I'm listening to the "MILITARY CHANNEL" as I write this...they are talking about the WW2 fighters made by Grumman, the WILDCAT and the HELLCAT. Roy Grumman's motto [according to the MC] was "build it strong and build it simple". He elected to build using air-cooled radial engines, etc., sounds like HD and Buell?! | ||

Oldog |

I don't know if the other sleds have different requirements but the fsm for the X1 calls for .015" or 1/64", Silas the local hardware or sears store has cheap dial calipers.  A Few skilled workmen can read a ruler or tape to that degree of accuracy, a telescoping gauge IF you have had instruction can be used, I have both and use the caliper, In a pinch use a short bolt nut and coupling nut as a transfer method, what you are looking for is the same distance back from the front edge of the adjuster pocket to the axle holder. There was a question on the accuracy of the pocket method, based on how the arm is made the locations of the machined surfaces is extremely close. My $.02 on why the axle has to be so close to parallel, has more to do with the belt than tracking, consider that the rear engine mount and swing arm are solidly mounted and the arm moves on tapered bearings ( precise alignment ) if the axle is not parallel the load on the belt is not evenly distributed and may cause tracking problems and or possible failure just re read your post sorry about the where thing fella, stupid question has the inflation of the tires been checked lately?, One last thought on the telescopic snap gauge the ends of the gauge are almost hemispherical if you were to slip or twist the device the reading will be off, usualy they are used to measure holes by transfering the measurement to an outside micrometer my o2 again the caliper will require less fiddling (Message edited by oldog on August 28, 2005) | ||

Silas_clone |

Oldog, I have and use a nice set of calipers, my Father-in-law was a prototype machinist and left them to me, very accurate, the axle is spec. I buy the belt theory...makes sense. Off for a ride. | ||

Jackbequick |

Another way to check alignment is to lay two 48" or so long straight edges (pieces of angle iron, 1x2 pine, etc.) on top of beer cans arranged like this: -o-----o--o tire---tire -o-----o--o Bring the straight edges into contact with the sidewalls on the rear tire and look at the gaps on both sides of the narrower front tire. It's amazing how a little error can be seen. And when you get the gaps the same, you can drink the equipment to celebrate! Blocks of wood will work too. Another trick, when the bike is tracking good and the belt tension is right, is to take a .5mm pencil and mark a line on on each end of the adjuster down inside the machined pocket. That makes it real easy to recover the original setting and also helps in making small adjustments. With the axle nut backed off 3/4 turn or so, you can put a piece of 2x4 against the axle nuts and tap them forward to seat the adjusters screws against the stop. The adjuster screws are 20 TPI pitch, each full turn of the screw will move the axle .050". My first choice on calipers is the $15 +/- LCD calipers from Harbor Freight. Instant inch/mm conversion and reliable/repeatable four way measurements accurate to within .001" or .002". I own about 30 micrometers and calipers, know how to use them all, and that LCD caliper is the tool I pick up first most times. Jack | ||

Patrickh |

I now use the "inside measurement" caliper prongs method illustrated by Oldog. I have also had very good results using 2 pieces of box section aluminum which are longer than the wheelbase. You raise the rear wheel off the ground. Point the front straight ahead. Lay the pieces of aluminum along either side of the rear tire, touching the edge of the profile, and measure the distance each piece of aluminum is from the edge of the profile on the front tire. adjust accordingly. If the right side of the front tire is further away from the box section than the left side is then you add more threads to the left side adjuster...and vice versa It is a bit of a fiddly process but works exceptionally well. | ||

Silas_clone |

I went for a little jaunt, but before I did, I adjusted the axle again, using my dial calipers. But this time I got down on the floor and read the left side measurement...prior to this, I measured the right [belt side] and tightened the thumb screw, then "felt" the left side. The I.D. tails on my calipers are too short to measure the left side with the dial up. Anyway, when I actually measured, the left side was .005 tighter. So now I know that a rear wheel biased to the right produces a left input and I know that it is better to "measure" than "feel", at least for that job. | ||

Mmmi_grad |

Harleys are aligning using old dogs method or as stated by Patrick H Jack be quick has the right idea also. I dont know of any better way to do it. Chassis alignment starts off that way and then you line up links on the motor. If you cant get a link to adjust you got a bent frame. | ||

Jackbequick |

SilasClone - "The I.D. tails on my calipers are too short to measure the left side with the dial up..." The cheap LCD's are called "four way calipers" (O.D., I.D., step, and depth) but actually have a 5th way of measuring I call "blind". To measure in the blind, put the caliper jaws or step/depth rod on or into the thing you want to measure and press the "Zero" button. When you get the caliper back to where you can see it, if you close the caliper you see the measurement as a negative value because zero is now out where you took the blind measurement. I've used the blind measure thing to shut up several know-it-alls who argued that their dial calipers were just as good and never needed a battery. Mine LCD caliper gets a new No. 357 battery every 12-18 months, at $1.50 each the electric bill is not that bad. Jack | ||

Silas_clone |

Well, I'd like to get some LCD calipers and I may try the rails system, but using the factory method plus getting on the floor to see the dial produced 100 miles of pure pleasure this a.m. | ||

Tramp |

actually, that microadjustment won't make any noticeable improvement. there's always some small bit of torque steer from having the drivebelt offset to one side of the axle, rose. don't overengineer a simple and natural phenomenon. | ||

Oldog |

I know what you mean Silas, I lock the caliper on the blind side or get on the floor. Todate I have only had to adjust the belt once in almost 15k miles so its probably all good for a long while Jack sounds like a handy feature, the most common error with any dial caliper is to apply too much pressure to them and get an erroneous measurement and possibly spring them, or have them tipped one or the other way so you are not parallel or perpendicular to the measurement. the inch - o - metric feature sounds nice. | ||

Izzinya |

there will be SOME pull to the left on ALL H-D style products the primary drive is usualy the "problem" you have a lot of stuff/weight on the left side of the bike a slight lean is "acceptable" by h-d stabdards if you have to shift your weight a considerable amount.... than i would look into other things...motor / wheel alignment | ||

Silas_clone |

Once again, truth is stranger than fiction... | ||

Tramp |

actually, the simplest solution is the correct one. torque steer due to offset drive. if you really feel a need to use a dial guage, do a low-end job  | ||

Blake |

Silas, Might you be hanging more of your mass off to the left? Either make the appropriate adjustments (Rossi does this during the parade lap so you'll be in good company) or try riding facing backwards and see what happens.  | ||

Jackbequick |

"..getting on the floor to see the dial produced 100 miles of pure pleasure this a.m." And that's what its all about. I think the service manual says that if they are within 1/64th of each other that's close enough. For the record that would be .015625" or 0.396875mm. Welcome back Tramp! I see the 6" LCD calipers selling on eBay for around $20 with shipping. There are a lot of things in any shop and around various hobbies that make that particular measuring tool arguably one of the most useful in the world. Jack | ||

Road_thing |

I bought one of those $20 LCD dial indicators on ebay, and I've been real happy with it. It's not an ultra-high precision measuring device, but it gets me within a couple of thousandths and I don't have to obsess over keeping it clean or putting it back in the box. My kind of tool! rt | ||

Tramp |

i still have the cool LCD they gave us in BMW tech training...While I DO use it for rear alignment, I find the torque steer is still there, esp. on belt drive machines, as there's more mediallateral slop in them than in chain drive. the real horror with regard to that bias is often wear in the adjusters, where the axle passes through. | ||

Silas_clone |

Soooo, once again I find myself obsessing over meaningless details. You know, this critter [M2] is a lot more like my '73 XL than I thought. Sure is purty, too. redneck to Bronson, "...what'll she do...?" Bronson to redneck, "...oh, she'll do plenty..." | ||

Tramp |

| ||

Jackbequick |

"..obsessing over meaningless details." I like that. Once someone that had lost their patience with me one time yelled "You're nothing but an anal retentive machinist!". I calmly pointed out that anal retentive and machinist were redundant and he went away and left me alone. Jack | ||

Tramp |

goood point. dang! | ||

Bomber |

measuring back there from the axle to the swingarm (factory method) will getcha pretty durn close -- my Y2K MaDeuece, when aligned using that method, was out a couple a millimetres (or furlongs per fortnight, I forget which) due to machining tolerances, I would assume I now measure from the hollow axle center to the center of the swingarm mounting bolt recesses with a shop made tool (it was slow in the entropy lab one night) -- howsomever, as Tramp alludes, even with the wheel dead nuts aligned with the swingarm pivot, there's lots of other places that can, and will, produce a less-than-perfect wheel to wheel alignment -- as few road are perfectly level, my scoot wanders off to the outside of the road (right hand side here in the states) more due to the crown in the pavement than to anyting else, I'm thinkin -- my tires wear evenly, the bike still outhandles me, and I figure I'll find something else to obssess over, like, o, spelling! ;-} | ||

Jackbequick |

After I noticed that the belt gets steadily tighter as the rear suspension travels upward I realized why the service manual adjustment does not work out right. If I adjust my M2 as per the SM and than sit on the bike, there is no slack in the belt at all, it is tight. So now my final check is to lay across the saddle hanging off the right side, lift my feet off the floor, and push the belt up. There will still be some slack in the belt. And the belt will loosen up a little more as it warms when you ride it. If you do that before and after a ride you get a feel for the amounts. Jack | ||

Tramp |

listen, fellers- while you're coming up with all these brave new belt-tension check methods, remember to check the TOP span of the belt, as well. | ||

Oldog |

bomber good to see yer that bak, | ||

Bomber |

thanks dawg -- a brief hiatus was all -- took a nice ride with my much better half round Gichee-Michigan -- great time, great weather, lots of fun | ||

Admin |

Will be moving this thread to the Knowledge Vault's "Drivetrain: Final Drive" topic.  Please in the future post all such tech related threads to the applicable KV topic. Please in the future post all such tech related threads to the applicable KV topic.  Thanks for all your help in getting the ol' BadWeB organized.  BadWeB Custodians | ||

Jackbequick |

Tramp - I just check the bottom run because it is easiest to get at. I'm not being facetious, and hope I didn't miss a joke. But if I push up on the lower run or down on the top run, wouldn't I see about the amount of movement? I can see where any droop could make a difference but there is not much of that. Jack | ||

Tramp |

no, honestly, jack- the bottom can be relatively snug when the top is really loose, AND vice-versa. all kidding aside. I think that's why so many people find their belt tension to "vary" so much. it's actually the same, but the lower span might be tighter when the upper's slack, etc. | ||

Jackbequick |

Okay, I'm going to take a closer look at that. Oh boy! Another detail to focus on, I wonder what I can measure it with... :>  Jack | ||

Reepicheep |

If it is in neutral, and you put upward tension on the bottom run, would you not then be taking up all slack regardless? That was how I always checked the 2000 Cyclone. Sit on the bike, reach down and lift the bottom run of the belt so that it just starts to get tension when it touches the swingarm. The XB9SX is easier to check and much easier to adjust... Look to see if the idler wheel is still there!  | ||

Tramp |

nope, won't take up all the slack, because the cogs still hold everything in place. take a close look- it varies, and it can account for that dynamic variance. |