| Author | Message | ||

Smokedaddy |

-SD: | ||

Panic |

Which years are sand-cast vs. permanent mold? | ||

Djkaplan |

I love it when people post pics of their projects. | ||

Road_thing |

NOW I get it--looks great! rt | ||

Easy_rider |

I really thought I'd prefer a lower maintenance chrome job as opposed to the polish -- but the flame job definitely throws me to the polish camp! How heavy of a media did you use to rough up the surface? | ||

Rick_a |

I did not know that. The steel arm still works better with a chain drive, which is the only reason I'm stayin' with it. I lived near Fredonia. Don't miss it a bit!...maybe the roads...when they weren't full of salt and/or gravel. | ||

Ceejay |

Darn nice work. making me jeolous. | ||

Ceejay |

you and your sidekick do nice work. | ||

Anonymous |

None of the cast swingarms were sandcastings for production. Semi-permanent mold for ALL serial production. Suppliers were changed, however, around 2001... | ||

Aaomy |

thank you anonymous for the clarification. i didnt mean anything buy it, i was just trying to point out where the weight difference ideas may have came from. once again thanks mystery guest. sorry for the slight miss information. about the media. not really sure, was justs a bag we had sitting around the shop. i will see if i can find out something for you tomorrow. i use two layers of tape, staggered seams, and run at about 40 psi. it starts to eat threw the first layer but not the second before i am done. and lastly about the copying my ideas. all i ask it that people give credit where credit is due. if some one asks just say where you got the ideas from. it is an issue i ideal with at work and hate seeing peoples hard work and intuition taken away from them. i always try to credit anyone whom has helped. ie. thanks fireman and spidy,, cool two of my childhood heroes? by all means copy and if you need help or answers to any question feel free to ask. if i didnt want to share with my bad web brothers so that they may copy i wouldnt have started this thread.. ((sorry if the last section sounded))preachy smoke daddy ,, that rocks,, did you do the engraving? | ||

Aaomy |

ok last night i got to take it out to seat in the rings,, yeah baby ,, i needed that!! so here are a couple pictures taken when i got home..    | ||

Aaomy |

oh yeah ,, things like this that i know are going to get a mess i spray with a clear coat, it takes away from the polishing a little bit but helps in the long run.. i always use, dupli-color, engine ceramic enamel in clear. it handles 500 degrees and dosent run when it gets gas spilled on it.. that the big plus for me. 1313,, thought you might like some flame pic's   | ||

Oldog |

I think Erik would approve | ||

Imeazy |

Very nice work Aaomy... really like the flames. Man, your sure got my ideas a running. I'm in the process of modifying the original can that came with my bike. Gonna have to stop and think for a bit before continuing (sp?). Thanks | ||

1313 |

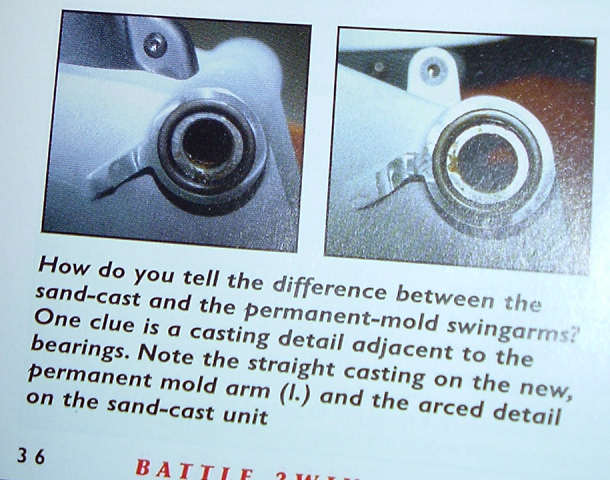

From an old issue of Battle2Win:  This is one point I beg to differ with Anonymous. The early production cast Aluminum swingarms were indeed sandcast parts. The first supplier did not have the capability to do semi-permanent mold castings at the time, but were trying to implement it. The supplier did change with the change to semi-permanent mold produced parts. FYI, it is semi-permanent mold because there is still a sand core (where the swingarm is hollow) that needed to be knocked out after casting the swingarm. Towards the end of tuber production the swingarm needed to be retooled (again in semi-permanent mold) and the latest version can be identified by the lack of the 'casting detail adjacent to the bearings' as mentioned in the Battle2Win article and some other refined features. 1313 | ||

1313 |

BTW Aaomy, the flames are awesome! Kinda makes me wish I had an Aluminum swingarm for my S2... 1313 | ||

Ezetobebad__uk |

Great work, come to UK & do mine some time, lol eze ps - bring the wabbitt | ||

Koz5150 |

Aaomy... I know a few things about sand blasting parts. See if you can figure out how I made this mask?  | ||

Anonymous |

Brankin - ya got me on a technicality - but you are not totally correct in your recollection of the dim, dark past... This is one point I beg to differ with Anonymous. The early production cast Aluminum swingarms were indeed sandcast parts The first supplier did not have the capability to do semi-permanent mold castings at the time, but were trying to implement it <wrong. first supplier WAS a semi-permanent mold foundry - their tooling delivery was late, thus the need to launch for the first several weeks with sandcastings>. Toward the end of tuber production the swingarm needed to be retooled (again in semi-permanent mold) and the latest version can be identified by the lack of the '}casting detail adjacent to the bearings' as mentioned in the Battle2Win article and some other refined features <toward the end actually close to two years before the end of the tubers (mid-life?) we retooled the swingarm at another foundry due unexpected/accelerated tool wear and BMC's unpleasant experience with the first foundry>. And that's the name of that tune. | ||

Oldog |

a Photo process Ken? like printed circuit boards are made with. Btw looks great, what is it?  | ||

Aaomy |

i was going to guess either with uv sensitive material, and wash process to make the mat. or the more expensive laser writer. and load anything into it, put anything under it and cut it out beautifully. i forget the other process like the uv cure but that would be my #1 guess. do you use a air brush with the sand blasting attachment to do that detail work.. ok so im dieing hear ,, how???? | ||

Djkaplan |

Wow. This thread wandered into some pretty obscure information only a real Buell nerd would be interested in. Cool... | ||

Aaomy |

so what project should i start posting next.. or any question about the swing arm? 1. billet xb to tuber front motor mount, 2. xb9 head prep, start of custom breather set up 3. new billet catch can and rest of custom breather set up. 4. billet foot pegs, to go with billet controls, and new longer billet shift control leaver 5. front sprocket lightening 6. rear sprocket cutting. 7. new al air cleaner assembly, with velocity and low pressure controlling cone. | ||

Djkaplan |

3. new billet catch can and rest of custom breather set up. | ||

Mmmi_grad |

best i can figure you used fine line tape. very thick fine line tape and then at low pressure slowley blasted the image in after carving it with an exacto knife? Lots of media to choose from, How did you it Brother! | ||

Bluzm2 |

Anony As usual,thanks for the "inside" scoop! This stuff is great! Brad | ||

Oldog |

Does this guy rock or WHAT!  Hey Aaron, I'm with DJ on #3 breather setup then #2, then #6 ALL BTW while Aaron it doing these posts, and working full time he has been assisting me with a little project of my own for My X1  Aaomy you are just too much ! keep it comming brother!  | ||

Oldog |

Kos: Howdyadoit? | ||

Aaomy |

koz 5150 so hows it done? please????? ok so i started another thread on a custom breather set up and billet catch can,, if you like these threads please chime in .. let me know what you like,, dis like,, or frost advisories like we got last night.. | ||

Koz5150 |

Some of the stuff I do is a UV type process to create the mask. Some of it is freehand. I have learned a lot of the past few years about how to screw it up. Things like, UV mask paper doesn't last forever, and is expensive. Blasting with the wrong sand or the wrong presure ruins the mask. Time is everything. There is no fixing screwed up chrome... Oil filters and other cheap parts use very cheap chrome and look cheap when done. There are also a few tricks I learned to make the UV masks come out clearer. Here is a few more things that will really get ya... I very rarely remove the parts from the bike. Also, try laying a mask on a surface with two curvatures? It's alot like trying to cover a basketball with a sheet of paper without creating wrinkles... For fun you can try it on a Sportster/Buell derby cover.  |