| Author | Message | ||

Road_thing |

OK, I suffered the "usual" stress fracture on the race pipe on my S1. After consultation with our resident structural analyst (that's Blake-he puts the "anal" in "analyst"  ) and my buddies at S&S Automotive in Houston (they don't do bikes--except for mine--but they do do drag cars and Donnie can TIG weld like a mo-fo) here's what I came up with: ) and my buddies at S&S Automotive in Houston (they don't do bikes--except for mine--but they do do drag cars and Donnie can TIG weld like a mo-fo) here's what I came up with:  That's a re-inforcing plate and bead of stainless all around the "affected area".  And that's the piece de resistance, a gusset to isolate the vibes further up the pipes than the collector. At least if it breaks up there, it'll be a lot easier to fix than if it breaks down by the collector. The 2 part gusset with the nut & bolt lets me flex the pipe enough to get it on & off the bike. I'll let you know how long it lasts... rt | ||

Reepicheep |

Very nice! But be honest sir Thing... was it originally a bolted gusset, or was that part enhanced later with an angle grinder and a lot of swearing between "rev 1" and final release? | ||

Road_thing |

Well, honestly I had originally intended to make it a one-piece gusset, but when I showed Donnie what I wanted, he said, "Well, yeah, but how are ya gonna take the pipe off after I weld it up?" Two heads are definitely better than one, especially if the one head in question is mine! rt | ||

Firemanjim |

Oh, my Gawd,look at that dangerous shock----!!!! Somebody please help that poor man. | ||

Firemanjim |

So you welded the bracket to the pipe instead of leaving it separate??Or was the S-1 pipe different?? | ||

Road_thing |

Jim, the bracket was welded to the pipe when I got it (on ebay) so I don't know if that's how it left the factory. It looks as though a DPO may have repaired the pipe before I got it. I do know that that weld has held up..so far! rt | ||

Blake |

Blake confuse. Why need bolt connection? Bolt add mass. Bolt make reinforce like week little girl instead big strong gorilla. More mass make vibrate more. More vibrate cause more mucho beaucoup problem. Me no unnerstan. Please esplain. Blake say reinforce like picture...  Most big problem... no reinforce back side pipe. Expose weak little girl bolt reinforce to horrible bad stress, no weld between pipe. You say how can be, me reinforce make more strong? Me say try see top and bottom pipe vibrate opposite way, one up, one down. Make weld area flex and crack same-same like failure before. Road Thing not listen Blake. Road Thing now maybe suffer horrible fate. Blake maybe come visit Road Thing. Maybe sabotage bolt. Of course, if Road Thing listen Blake, maybe fate be even worse. Blake just guess about good fix. Maybe weak little girl bolt fix on one side work okay. Blake now show idea for optimum reinforce race header... ![: ]](http://www.badweatherbikers.com/buell/clipart/proud.gif) (Message edited by blake on April 05, 2005) | ||

Blake |

Clarify... Should no need flex pipe for remove from engine. If pipe need flex for remove from engine, pipe no have good shape. Must make pipe good shape. It not too difficult you make pipe good shape with oxygen torch. Maybe require patience though. | ||

Bomber |

er, Blake? I'm thinkin you need to come north for a little while, bud -- it's clear that Thang is so enamored of the obviously well-developed welding skill shown above that he is slowly converting his entire exhaust system into a series of weld beads .. . . . THAT should hold up, yes? (Message edited by bomber on April 05, 2005) | ||

Road_thing |

Blake: Donnie no have red rod, no can do like Blake picture... Shape may not be the same on my pipe as on yours--note the gap between the pipes. Probably the result of repairs by the DPO. I'm working with used parts here, so it's "patch, patch, patch" and hope it holds up. If it breaks again, well, I just bought another used pipe from that nasty fireman in CA. I'll just cut & fit and patch some more! Ain't these things fun? Who'd ever want a machine that doesn't need to be farkled with once in a while? I put the pipe and muffler combo on back in '02--I got almost 3 years out of it. Judging from what I read around here, that's not bad pipe life! Here's a link to my posts at the time: http://www.badweatherbikers.com/cgibin/discus/show.cgi?tpc=3842&post=101251#POST 101251 I had to section the collector to get everything lined up then. Clearly the pipe is not pristine, toplogically speaking. But feel free to come on down--April 16 at el Ranchito Chingadero! rt | ||

Road_thing |

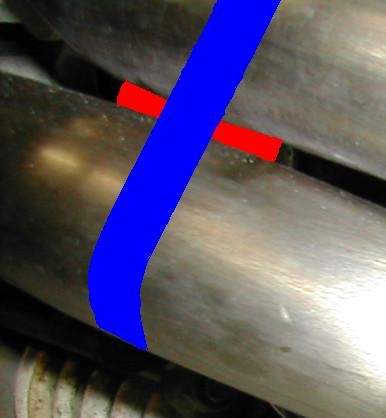

Hmm, I see your point about just bracing one side, though. What if I were to make a little "cradle" to fit between the pipes and conform to their contours, then band them together with a clamp of some sort, like a hose clamp. That would keep them from vibrating "out of phase" with each other, wouldn't it? Here's a cruddy pic of what I'm thinking:  Red=cradle, Blue=clamp rt | ||

Henrik |

I'd say add supporting struts (as Aaron suggested some years ago), similar to the stock pipe support, from the front shock bracket to each of the headers. Henrik | ||

Firemanjim |

RT,the correct front mount is clamped on,maybe a cause of your problems was welded one??I sent one along to you,bunged up though it was. (notice how I adroitly avoided mentioning anything about his nasty fireman comment) | ||

Wyckedflesh |

Just remember, if your canister drops the same way mine did...well its one hell of a painful ride... Where you have your bracket and reinforced is where the new elbow pipe wth bracket was going to be welded, but with a secondary attatchment of the pipe higher up on near the collector. Unfortunately the temporary P clamp I used came apart allowing enough flex for the elbow and V&H to seperate, bend the rear bracket (3/16 thick) and catch the asphault... | ||

Rick_a |

My collector area is becoming a collection of welds, too. Not as extensive, though. Right now I'm trying a rigid front and rear mount. So far no problems in a few thousand miles. |