| Author | Message | ||

Henrik  |

Non Buell content - reader beware  I got started on door trim and baseboards this weekend, and can truly say that miter joints suck! Wasted quite a bit of back band trying to get tight joints around the door frame. So, any recommendations for how to measure out miters, determining cut angles and hiding my mistakes? From web and book searches it seems that coping is the way to go for inside corners ?? Any hints for easier coping? Would you cope on a bevel as well? Keep in mind I'm a hack at this, and I'm doing really basic stuff here - mostly baseboards. Thanks Henrik | ||

Gowindward  |

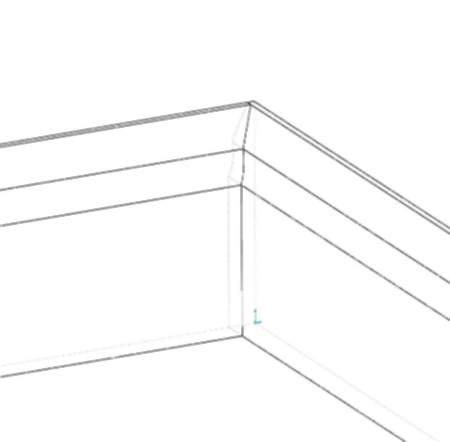

Would you cope on a bevel as well? Not if it's a 90 deg joint. Okay see the piece on the LH side. See it's cut at a 45 deg angle. Then to cope it cut following the line created by the 45 cut along the surface closest to you in the image. See the next image for how the joint then fits together.   | ||

Henrik  |

Loren - that's so friggin' cool!!! Thank you! I've searched and browsed all kinds of DIY and woodworking sites; all of them referring to 45° and coping. Except I didn't understand a bit of it. You explained it perfectly in 2 lines of text. Excellent. Thanks again. Henrik | ||

Gowindward  |

You're welcome! Well...You know two pictures are worth 2000 words...maybe even a little more. LOL | ||

Paulinoz  |

Henrik in the same vane as above when you have cut the 45 deg to use the copping saw on rub the side of a lead pencil down the front edge this makes it easier to see and follow. Joints should be cut so the part is slightly longer and has a slight bow in the centre prior to nailing, this gives you a tight joint. | ||

Oddbawl  |

One thing I learned the hard way working on a turn of the century house is DO NOT ASSUME EVERYTHING IS SQUARE! Corners, doors, everything can be way off. I had to measure each joint individually and set up my angles accordingly. One way to trash $75 worth of prime oak door casing is to measure it up, cut nice square joints with machine precision and slap it onto a doorway that's 1/8" off. That and the mantra I have in bold letters over my woodworking bench: MEASURE TWICE, CUT ONCE. p.s. Those new fancy laser dealies that show where your saw's gonna cut kick @ss. (Message edited by oddbawl on January 18, 2005) | ||

Court |

>>>DO NOT ASSUME EVERYTHING IS SQUARE! 1912 model here. | ||

Koz5150  |

There is not a square corner in my 1954 built house. I did however find a newspaper in the wall when replacing the bathroom medicine cabinet. I guess Milk went from $.21 to $.22 that year. It was the headline. There were also some pretty grousome pictures of a train wreck. | ||

Mikej  |

Our house is from somewhere between 1880-1905. Ripping up some carpet, found tile below it, found a layer of newspapers from 1953 below that and above the wood planks which were held down with square nails. I think I've found a total of exactly one square corner in the house so far. I'm going to have to steam bend some moulding trim for the kitchen ceiling, that should be fun, but I'll be able to then use the steamer for some boat building later on. | ||

Oddbawl  |

Gonna put a v-twin in the boat? | ||

Mikej  |

Maybe...  | ||

Odie  |

Henrik, if you still need help Lowes, Home Depot has some great books on trim work. Simple to elaborate. Good luck, and like everyone has said already, don't always assume it is square or straight...Odie | ||

Henrik  |

No square corners in my house either. Built in 1929, and between some sagging/settling and several less than perfectionist owners, it's pretty much guaranteed a square cut will be off. But I'm learning  So while I at this time have more than enough junk lumber for an Equinox Bonfire, I'm now measuring *at least* twice, and the kindling production have gone down. Thanks for the hint Paul. I've been trying to cut a hair long, but then had trouble pushing the pieces in place. The "bend in the middle" is a good idea. Laser miter saws; I've been drooling over those, but have also been wondering how accurate the laser line is in relation to the blade and the blade thickness. For back band trim, I found out (the hard way  ), that I needed to take into account where my cut line was in relation to desired length, and align the blade perfectly in relation to the line. I guess that ought to be obvious, but still ), that I needed to take into account where my cut line was in relation to desired length, and align the blade perfectly in relation to the line. I guess that ought to be obvious, but still  Henrik | ||

Blackbelt  |

I have a house built (as far as we can find out so far) in 1870's, cause while tearing out the upstairs (for complete remodel) i found an Arithmatic book from 1876, stuffed in the insulation, behind the laithen plaster. How cool is that? We ended up taking the entire 2nd story off and rebuilding off the floorboards... talk about fun. 2 Years later and a ton of sweat, blood, and headaches, the 2nd floor is done. And i am starting the trim work now, and let me tell ya, when you build new construction atop of old (VERY OLD) construction you still will NOT have square corners.. frigging sagging house.. lol. Thank god for power Mitor boxes.. lol.  | ||

Oddbawl  |

The laser on the saws indicate one side of the kerf (width of the cut) not the center. Count on losing 1/8" to the blade. The laser's more accurate than a pencil line, for real accuracy use a striking knife. www.leevalley.com is my happy place for that kind of stuff. the laser I have fits on the arbour, look into your saw mfg, you may be able to retrofit one. Also check yer local Home Depot or wherever for demos. I've been kicking around woodworking for years and I'll never go without my laser guided eq. now! | ||

Wyckedflesh  |

Henrik, try using some of that "Kindling" for testcuts on some of the less square corners. Not so much for the over 90degree ones but for the less then 90degree corners. This way when you get it just how you want it, then you use the mitre from your test peice on the one you want to put in place. | ||

Henrik  |

My saw is a cheapo Ryobi, bought as part of a 6 piece kit. The plastic box it all came in becomes the stand for the miter saw. Pretty cool kit, and the tools have many times over made up their modest cost of $399. Unfortunately Ryobi doesn't make a laser kit, and a new dual laser Porter Cable is not in the cards ... just yet  Good to know how the laser line works. I've been wondering. Kindling test cuts - great idea. I'm going to try my hand at the coping, since it - to my untrained eye - seems like I'll have a hair more leeway in cutting the pieces to length and still getting a tight fit. We'll see ... Thanks again, all. Henrik | ||

Court |

Doc: Take a moment and count your fingers for me and report. I need a "baseline" for this upcoming season.  Hurry up and get done with that fancy saw....I may need it. Court | ||

Leftcoastal  |

Here's a couple of tips that I always told my new 'hires' before they started in with any power tools: 1) Meat is softer than wood. 2) Wood, though once alive, is actually a non-sentient species - Don't let it kick your @ss! Hope that helps you amateur carpenter/homeowners. After 25 or so years as a professional woodworker, that pretty much sums it up - the rest is mere details. AL | ||

Henrik  |

Court; far as I can count without removing my shoes and socks - there are 10 digits left  Fancy saw will hopefully be decommissioned in a couple of months ... fingers crossed - 2 of them Fancy saw will hopefully be decommissioned in a couple of months ... fingers crossed - 2 of them  Meat vs. wood; my neighbor is a contractor and read me the riot act about safety. I sometimes stray, but usually wear all the gear and think twice before cranking up saws and other power tools. Of course some years in ERs and the things I had to deal with there inspires me to take extra care as well. Henrik | ||

Ingemar |

I don't think they had measuring tools in 1890 ... I know NOTHING is square NOR leveled in my house. Putting in the kitchen was quite a challenge. I even have a wall that is square at floor level with another wall but not at the ceiling  . You should have seen the guys' face that had to replace the window in that wall ... . You should have seen the guys' face that had to replace the window in that wall ... | ||

Henrik  |

Ingemar; I know that feeling of nothing being square for more than a few inches at a time ... only I have to deal with all of this myself, without the benefit of know what I'm doing  . Melissa has learned quite a few elaborate danish curses in the time that we've been working on the house. . Melissa has learned quite a few elaborate danish curses in the time that we've been working on the house. Henrik | ||

Ingemar |

I hear ya Henrik. I'm not a construction worker and barely new how to drive a nail in a piece of wood. I bought this house a few years ago in nearly its original state. I thought I knew what I was up to. I was a fool. I know better now, and after 5 years of hard work and frustration the first floor is nearly done. |