| Author | Message | ||

M1combat |

I've been looking at this model of the 12 exhaust can...  My goal is a deeper sound and I don't want to loose power. I don't want to disrupt the beautiful torque curve. If I could gain power I suppose that would be cool, but I'll be getting a Drummer at some point anyway. I've got two ideas... I was thinking of cutting a long hole along the top so I could get in there and cut the center pipe out. My second idea is to cut the right and left pipes out and cap the holes where they go through that rear plate. With this idea would it be better to screen the two holes and pack the rear of the muffler? Because of the way the valve works, I think that I would break even (for the most part) at the top and bottom, but gain midrange and have a deeper sound. I know one thing for sure though... I'll need to get a book on exhaust principals and do a little thinking. | ||

Trenchtractor |

M1, the left and right pipes are pretty small, like 1.5" and 1.75" or there abouts... One of them has a series of perforations in it. Can't remember which one... The center one is 2". There is plenty that could be done. I'm working on a 12 set-up myself, but I won't disclose details until I have it working... It's taken a few dyn runs to get to where I'm at and I'm still not happy. Plus I been off the bike for the last 5 weeks... Sucks. | ||

M1combat |

Hmmm, If one of them is perforated that kind of blows my theory out of the water then... Damn. I'll keep thinking though... | ||

Nxtr |

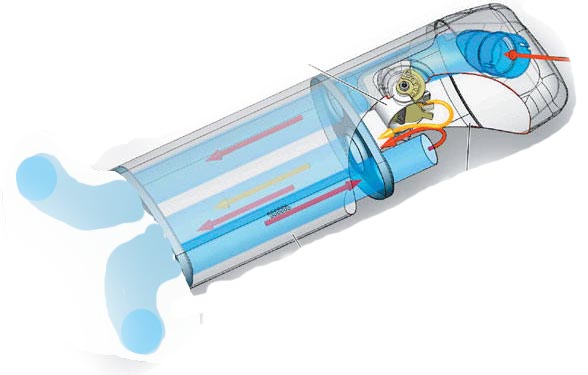

I have an in-depth idea for both the 12 and 9, but I am currently on the road. However a quick fix that would work on both the 12 and 9 would be (referencing the above picture) cut off chamber A between the tacked on stainless outlet and the three hole reinforcing plate. Then weld a U pipe from the first pipe (that exits into chamber A, to the third in chamber A that is perforated in chamber B, and exits in chamber C.) Then remove the original exit pipe that was attached to the center pipe, and clean up the end so it is flush with the three hole reinforcing plate. Then elongate the hole in chamber A to match that of the tacked on outlet. (I would slide the stainless outlet through the inside of the elongated hole, tack it then run a smooth bead around the outside. This in my opinion would give it a much better look) Then weld chamber A back to the muffler body, grind weld and repaint. This mod should result in no loss of HP or TQ, and give it a nice low tone at idle and non ear splitting growl when you get on it. This is nothing more than my own personal theory. But to date I donít believe it has been tried. Then again I may be wrong. V/R, Nick (Message edited by nxtr on October 20, 2004) | ||

Glitch |

It's sloppy, but I don't care.  I care, I just don't have the time... | ||

M1combat |

I guess I don't see the point of moving the stainless outlet, but other than that it seems like a decent plan... I'm sure it will affect power in some fashion because you are changing that first chamber volume. I think that to get some of that volume back you may want to perforate pipe number one (on the left) in chamber "B". | ||

Nxtr |

M1, the point of sliding the stainless outlet from the inside out in chamber A is only for a clean look. I am sure you could simply elongate the hole and leave it tacked in place. The volume change would be minimul(sp) since you now make chamber C the first open chamber. From the initial drawing it looks as though the only pipe perforated, is the one from chamber A to C. So once chamber B is full it is a mute point anyhow. P.S. I know see the confusing chamber B part in my original post and I have fixed it. V/R, Nick (Message edited by nxtr on October 20, 2004) | ||

Xbolt12 |

My two cents would say the pipe design is simple, long path for lower rpm, short path for higher rpm, ie: changing the tuned runner length so the negative pressure reflects at the exhaust port at the ideal tuned rpm. My guess would be shorten all three pipes, but add diameter at the same time, so with the lower velocity the exhaust still gets reflected at the same time/rpm. You would then get the same tuned rpms, with lower backpressure and louder sound. xbolt12 | ||

Trenchtractor |

Actually, the first two pipes are smaller in diameter than the third, so there is flow restriction in the long path as well. | ||

Fullpower |

with an effective operating range of 2500-6800 rpm, i maintain that the exhaust flapper valve is completely unnecessary, and was put in only for EPA noise compliance. | ||

Deerhunter17 |

the down side to all of this genius is that you need the stock ECM to work the valve. Any change to the pipe will change the optimum rpm ranges for the valve to be opening and closing. I don't see a benefit in modifying a 12 pipe, with out a programmable ecm. jmho | ||

Xbolt12 |

I would agree with a properly sized straight through pipe. That is why I put a Jardine on my xb12r. It does lose some power down low though and I think it is tough to beat the spread of the stock pipe and still get power gains. My guess is the drummer is the closest to reaching this ideal. Me I wanted maximum power and don't care too much about low end. I do feel the mid-range is a little soft now though I think future mods will more than compensate. xbolt12 | ||

BadS1 |

Try a D&D on the 12's trust me. | ||

Deerhunter17 |

Drummer with race ecm.... awesome! Was skeptical before doing it, but once the tps was reset ... dang that thing will go!!! and sounds soooo much better | ||

M1combat |

Don't they have a pretty sizable dip in the mid-range Dana? | ||

BadS1 |

Deerhunter the Drummer is a great pipe my bike was the second 12 to get the Drummer infact.Was suppose to be the test pig but I was chicken.Gearloose was the test pig.After awhile I wanted a change so what the hell I bought a D&D and through it on.Holy crap this things running even better.It pulls almost violent to redline.M1...Nope no sizable dip in the mid range. | ||

Xbolt12 |

Hey guys, I just got a plan (no not like Kerry, a real plan  . Open up the pipe and attach the outlet pipe to the pipe at the top of the diagram, then take the middle and lower pipe out and weld in a open megaphone. Next rewire the servo control from the motor to a switch next to the throttle which switches the motor control to ground when on. Install a modified version of opto's circuit to keep the engine check light off. . Open up the pipe and attach the outlet pipe to the pipe at the top of the diagram, then take the middle and lower pipe out and weld in a open megaphone. Next rewire the servo control from the motor to a switch next to the throttle which switches the motor control to ground when on. Install a modified version of opto's circuit to keep the engine check light off. Presto! What you end up with is an electrically switchable exhaust cutout when ever you feel the need! heh heh  xbolt12 | ||

M1combat |

Cool... That might be useful with the race ECM. Hmmm... More to think about. I wonder if a person could rig something so the opening of the valve is linear with the throttle and then tune an exhaust around that... |