| Author | Message | ||

Upthemaiden |

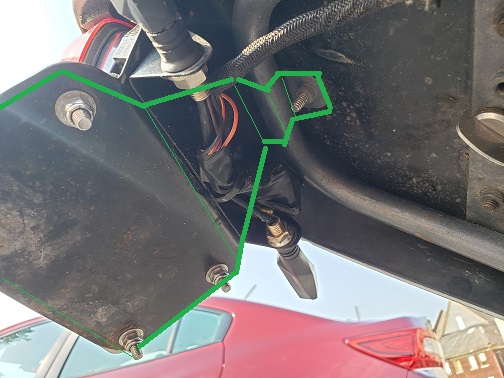

I'm curious what other S1/M2 owners do with their exposed turn signal/tail light wires. I've tried making various little covers out of some 1/8" plastic that bolts on under the bolts that hold on my license plate, and then I'll heat it up and bend it so it nicely covers all that stuff to keep water from my rear tire from beating on it, but this bike shakes so much that everything always ends up cracking. I assume I'll just have to make something out of steel instead of the plastic, but I was curious if anyone has come up with anything nice to cover all of that. I temporarily wrapped the whole clump up in electrical tape and zip tied it to the tail light bracket, but I'd like to come up with something a little nicer than that. | ||

Upthemaiden |

| ||

Wcbrracing |

Use some 3/8 or 1/2 ID poly tube to run the wires thru, tubing can hide or you can use it as a chase for the wires and easier to tape or zip tie up tighter than without…head down to the hardware store, check plumbing and the irrigation aisles for tubing…. Gawd I HATE the sticky residue electrical tapes leaves on wires after a long time. | ||

89rs1200 |

Hmmm, Poly tubing. I like Sleeving, Braided, Expandable, PET (Polyethylene Terephthalate). It comes in may colors, expands to fit connectors inside. Ends can be folded back into itself or taped, or heat shrunk; https://www.newark.com/pro-power/8465-0232/sleevin g-expandable-19-05mm-id/dp/52N9772 Or Sleeving, Flexible, 8 mm, PP (Polypropylene), Black. Can be found in hardware and auto parts store; https://www.newark.com/pro-power/kl8bk/sleeving-fl exible-8-mm-pp-polypropylene/dp/47T2148 | ||

Wcbrracing |

Yes Poly tubing, I’m a plumber as use in in biotech labs for air water and gasses…3/8 I’d poly tube worked awesome as a chase/conduit for the wires for extra dome lighting in the camper shell on my truck. I cut the glued carpet at the start and end, and physically pushed the tubing from one end to the other, then pushed the wires thru. . I agree the braided flex is another good idea, the corrugated kind would work as well. Also, They do sell heat shrink tube In 3 foot lengths, I found them at electronics stores…usually in black color, but sometimes in white and red | ||

Kc_zombie |

Did that bike have the Twin-Tail on it at some point? For some reason I have it my head that the tail lamp harness was longer for the twin-tail kit. I dunno, I get hit in the head a lot..  | ||

Upthemaiden |

It's always been a solo tail, there's just a few extra wires under there. I would assume the twin tail bikes had the same harness, but they did have a longer rear support/tail light bracket. Mine looks extra messy because the oem tail light has the plugs mounted right on the body, so all you'd have loose are the couple turn signal wires. Mine has a Ulysses tail light with about 4" of lead wires to it, and then my turn signals also have extra wires because they have a brake light function to them, so it's a little more chaotic back there. A poly tube sounds like a good idea to protect it. I'd have to get creative to find away to run cables from 4 different directions together to feed them into the side of a tube, which is why I had always just made some kind of cover to go over the whole area to keep water from getting thrown at them. I feel like clumping them all together is probably better for the vibrations, although I agree that sticky electrical tape residue is a nightmare. I do have some pretty large heat shrink, maybe I can see what I can do with that one. | ||

34nineteen |

I will need to see what I did on my bike after I'm done with my move. I think I used a P-clamp to act as a hook to hold the wires up and out of sight. | ||

Upthemaiden |

I think the best solution is if I get some time is to make something similar to what I've tried, but instead of making it long enough to cover the wires, I should make it long enough to reach to bolts that hold the tail bodywork on, replace those bolts with longer ones and bolt it on there with some extra nuts. That way it's supported at both ends and won't crack like all of the old ones have. This is the shape of the piece that cracked(at the red X):  This is what I was thinking of trying:  Another option if I wanted to keep it smaller is just to use the one bolt at the very back that holds on the tail light bracket:  My apologies to the people who have advanced beyond Microsoft Paint for their design work haha. I'm leaning towards the longer one, and extending it even further until it meets the back of the oil tank. That should keep any of the rain water mess from getting up on top of the oil tank and onto the bottom of my seat. | ||

Mstrfrz |

just a piece of box tubing betwen the turn signals using the same bolts that hold the taillight on ought to do it, with strategic holes for the wires to in and out. | ||

34nineteen |

You could pick up a small sheet of lexan from Home Depot and bend it to shape with some heat and a vice to use as a brake. Just make a template with some cardboard and transfer it to the lexan. In my SV650 days, I would do that to make a tail tidy for the 1st gen models. Someone made a template for it and it was available on the forums. I liked it. Rather than attaching it to the 4 license plate mounting bolts, maybe have it wrap upward and sandwich between the license plate mount and the turn signal mount. A piece of sheet steel would probably work better for this. You may want to consider a piece of PVC tubing between the turn signal mounts. You could hide the wires inside the pipe and make a small exit hole to line up with the harness. I'm sure I'm missing an important detail to this. | ||

Upthemaiden |

Fitting some kind of tubing between the turn signals sounds like it'd protect everything well, but if I cover that area up there's not really a way to get to the tail light mounts to bolt it on. Lexan is probably a better idea. The plastic I have is similar but it's a little bit lighter and more flexible, so I think it cracks easier. I have some 1/4" stuff already but I think that's overkill. I think the stuff I've been using would work as long as I find a way to support it from both ends, instead of letting it vibrate like it does. | ||

34nineteen |

My mind says you should be able to unbolt the bracket and flex it to fit the get the tubing over the threaded portion or nuts of the turn signals. Once you get it fitted, you *shouldnt* need to take it apart again. I may need to try this on my bike after I get my move done. I still havent painted or mounted up that Airtech pulley cover. |