| Author | Message | ||

Fullauto |

I'm in the midst of replacing my sprocket shaft oil seal. I have all that I need but no installation tool, HD-45206. Anybody out there have one or could get one at short notice? Will pay all costs of course. I'm in a very remote part of western Australia. For anybody making their own, I suggest that you make it longer so that you don't need a spacer to seat it. If the tool was long enough, the nut on the end of the crank would do the job. HELP! | ||

S2pengy |

PVC pipe might work.... | ||

Bluzm2 |

Are you referring to the crank shaft seal? If so, the tool is less than $20 US. I ordered on from Appleton HD a while back. It has installed at least a dozen seals. I use a piece of PVC as a spacer so I can use the crank nut. Due to the cost of shipping, I'd just order one and be done with it. Most pre 2002 tubers will need it sooner or later as the seals will evertually leak. I have been amayzed at how hard and brittle some have been. Brad | ||

Fullauto |

Thanks guys. Pvc pipe won't work because it's a double lipped seal, therefore no flat bit to push on. I've contacted Andy at Appletons and he can get me one in a week and a half. I might have to go with that but I hate having the X1 out of action for so long. I'll just have to console myself with the Norton........... Thanks again. | ||

Reepicheep |

I used a green tinker toy. It worked perfect.... the second time I tried it. Just don't seat it too deep, and a shaped wooden dowel (you can put your own depth lip on it) will work fine. The tools a good investment though. | ||

89rs1200 |

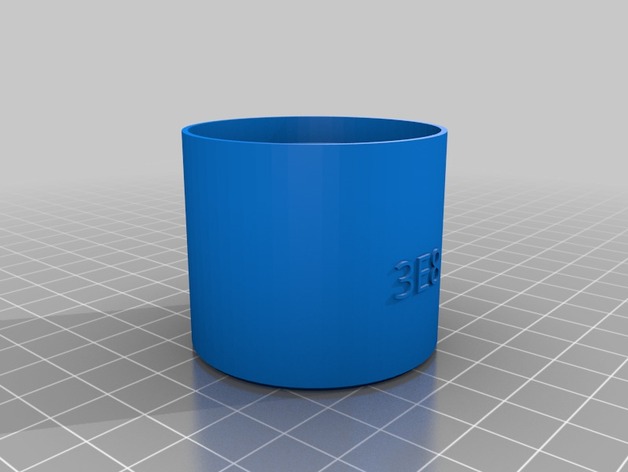

I found and purchased the 3D printed HD45206 / HD-45206 / 45206 Sprocket Shaft Seal Installer. * Only $16 for two, and yes, it is plastic, but it worked great without deforming! * The taller tool is just the right height as no spacer washers were needed. * It worked! Could not have properly installed the seal without the tool. The seal sits out a bit from flush with the opening. I would have seated the seal too deep without this tool. https://www.thingiverse.com/thing:1784320 This taller one will not need spacers as it is just tall enough to use the stock nut to press the seal in;  Copy of the Harley tool HD45206 / HD-45206 / 45206 Sprocket Shaft Seal Installer;  | ||

Lurchandy |

I was about to suggest the same thing. You can download the print file from thing universe and Im sure the WA libraries have 3D printer and you can pay online and upload the file and just pick it up when its done. If PM me and I can get one done here for you in brisbane and post it over to you. | ||

Froggy |

I have a 3d printer so if anyone in the future needs one of these, hit me up and I can take care of it. | ||

89rs1200 |

To complete the discussion as to how to get this part printed: 1) Download the file from the above link. I recommend printing the extended tool, (HD45206_ext.stl). 2) Go to this site to upload the file and select someone to print it; https://www.treatstock.com/my/print-model3d |