| Author | Message | ||

Gvelox |

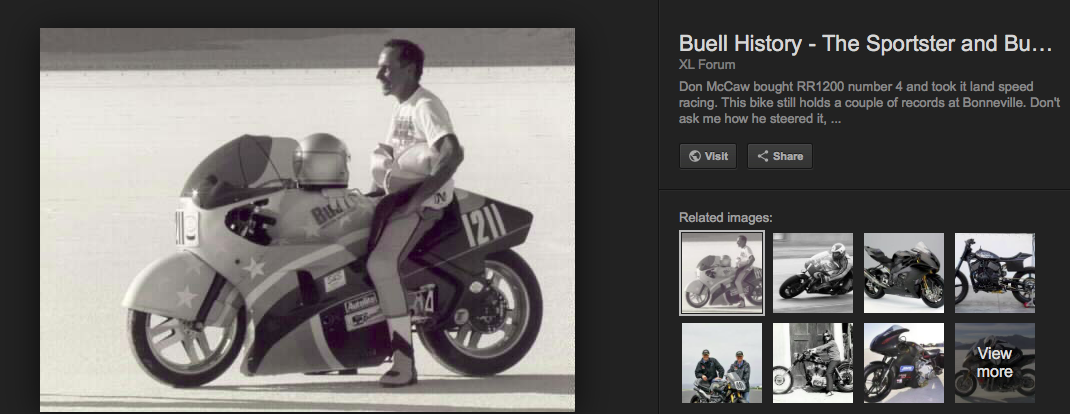

There's an interesting M2 on eBay right now being sold by Don McCaw. In the listing he says "I also changed the front engine mount to make the mount bolt perpendicular to the engine rotation point at the rear of the transmission/swing arm pivot, resulting in a much smoother ride experience." I'm wondering if there's a member that would be willing to elucidate that concept or perhaps knows Mr. McCaw and ask him to do a posting about it. I asked him to post a picture of the mount but didn't get a response. He's a member of BadWeb as Dynodon but his only postings are from when he tried to sell this bike back in 03. | ||

Dannybuell |

my bravo sierra meter translated this to: the rubber on the front mount was torn and replaced with a new frame to motor mount. the bike handles well without all that slop between the handle bars-frame-engine. | ||

Upthemaiden |

I remember reading that and had no clue what he was talking about. I didn't know if he had a new front engine mount machined and rewelded the isolator mounting tab to change the angle of the whole setup? From what I gathered the isolators were designed to allow vertical movement of the engine, and the tiebars were supposed to limit travel in any other direction. I'm not sure how you could change something to be perpendicular and still have it functional. Someone buy the bike and tell us what he did. edit: I tried emailing him to ask about it, and the email got returned to me. Not sure what the story is with that. (Message edited by upthemaiden on June 11, 2018) | ||

Gvelox |

Dannybuell, normally I'd agree with you but Don McCaw is the real deal. He's an engineer with Deere and has quite a history with Sportsters and Buells. Upthemaiden, thanks for the try. His registration is quite old so the email is probably out of date. I sent him another email through eBay, hopefully he'll respond. | ||

Upthemaiden |

"Upthemaiden, thanks for the try. His registration is quite old so the email is probably out of date. I sent him another email through eBay, hopefully he'll respond." The email I sent him was through ebay but it still came back to me. It gave me some weird message about an unauthenticated email from yahoo.com not being accepted due to domain's. Who knows. I do agree the bike looked impressive. If someone wrote that in regards to a beat up $2000 bike, I'd be very suspicious. With all the work done to that bike, I can't imagine someone doing something to it that wasn't legitimate. | ||

S1owner |

https://rover.ebay.com/rover/0/0/0?mpre=https%3A%2 F%2Fwww.ebay.com%2Fulk%2Fitm%2F332676649864 | ||

Court |

I'd ask more questions . . . . this may be more interesting than you think. | ||

Upthemaiden |

I ended up hearing from Don last night. This was his response: "The stock front motor mount bolt is situated straight up and down. The engine pivots on the same center as the swing arm pivot; as the engine moves, it rotates around the rear swing arm pivot. Because the engine is moving in a rotational motion (not straight up and down) the front mount can't do it's job well because it's positioned for straight up and down movement. I tip the mount bolt, bottom end forward, so the mount bolt is perpendicular to the swing arm/engine pivot. Now the mount can do it's job well. Draw a circle, from the center draw a line at a 45 degree angle to the circle (upper right portion of the circle). The bolt will be on the line of the circle where the line touches the circle." So in my rough Microsoft paint skills, I assume the new isolator angle is about where the green line is in the picture. I'm assuming he had to have a custom engine mount made and rewelded the frame to accept the isolator at the new angle.  | ||

Gvelox |

Thanks for the drawing. Mr. McCaw was kind enough to respond to my email also. It makes a lot of sense. I wonder why Eric (or anybody else for that matter) never thought of that. | ||

Dannybuell |

Thank You All for this, much learned. One ? Would the intersection of the blue line with the green increase the shear, stress on the bolt? | ||

Upthemaiden |

That's what I was wondering earlier. I was also thinking wondering what additional forces were put on the setup by not having the bolt vertical, for the engine to actually hang off of the isolator. I'm not an engineer though so anything in my head is just speculation. I did get another follow up email from him. He said there was no modification needed to the frame, he just made wedges that fit under the isolator to pivot the top of the bolt towards the rear of the bike. The front mount to the cylinder head does need some modification. I don't know if that means he made an entirely new mount, or if he was just able to change what appears to be the stock mount. It's hard to picture without looking at my bike, but with the isolator still in the same spot, and the bottom of the bolt being swung out forward towards the front of the bike, I don't see any way that that bolt could still come in contact with the engine mount that's typically behind the isolator. I may email him back eventually to see if he has any kind of pictures of the modification just to see what's going on. | ||

S1owner |

What would be nice is if someone could convince him to get on this thread and share his obvious vast wisdom before it all gets lost to the gods! | ||

Dmccaw |

Upthemaiden has it correct in his picture in the June 12 2018 @ 0748 am post. The green line is where the bolt should be to get best use of the rubber cushion. The shear force will go nearly to zero and the tensile force will increase, so a bolt of supreme quality - like the original - needs to be used. If you take the gas tank off and go for a ride with the stock bolt, you will see the bolt head moving back and forth - a bolt does not like that. If there is fore and aft movement in a bolt, it needs to be a solid metal-to-metal joint with a lot of torque to prevent any tendency for shearing action. | ||

Upthemaiden |

Any chance we could get some pictures of the setup so we can stop racking our brains over it?? haha | ||

Court |

>>>>>I wonder why Eric (or anybody else for that matter) never thought of that. Not sure who Eric is . . . but, I confess, when I see someone telling me that are very well versed in all things Buell and do not know the spelling or Mr. Buell's name . . . . it gives rise to a level of skepticism. If you need something to wonder about . . . I would suggest you wonder why Engineers like Dave Ulicki, Abe Askenazi, John Fox and Bret Schaller modeled all these various designs in tools like ProE and Think3 and rejected various designs in favor or the one that got built on the bike. No one . . . has ever spent more time . . . tens of thousands of hours . . . looking at various engineering options . . evaluating them and selecting the best after thousands of hours of extensive testing. . . than the engineers at Buell. Just another thing to think about . . . . | ||

Gvelox |

My deepest apologies. I didn't mean to offend anyone. What I meant and what I should have said was I wonder why this design wasn't used. | ||

Upthemaiden |

I'm on my second Buell and I've loved the things since I was a kid. I still have a hard time remembering if it's a C or a K sometimes. Details. I've been called every name that starts with a J, I'll answer to pretty much any of them at this point haha. | ||

Dmccaw |

Check out the newer Buell motorcycles, and you will see that Erik and crew have the bolt as pictured in Upthemaiden picture. | ||

S1owner |

No matter how much engineering and testing sometimes the reworld riding shows us things we could not lab create. That could be why they did not do it originally but then swapped to that angle in the XB models. Being a guy that deals with engineers all the time sometimes they just get trumped by time and reworld testing. If Erik and all the engineers knew it all on the first tubers we would never have seen newer updated bikes from them! | ||

Lynrd |

Erik  and team are good but not everything they did was perfection no matter the hours taken - sometimes, you have to make compromises for manufacturing reasons. and team are good but not everything they did was perfection no matter the hours taken - sometimes, you have to make compromises for manufacturing reasons. I will point to the bent leg in the triangle for the front anchor on a 97-98 S3 as one example of a design compromise. They took natures strongest shape (the triangle used on the S2) and put a spring in one leg of it by bending one leg. I just chalk it up to Harlification. The engineering here rings true. If someone got the angle of the dangle, they could probably machine some Phenolic or aluminum and sell some - this makes more sense to me from a chassis geometry standpoint than "Stenzel bars" and people buy those... | ||

Classicbuells |

Just to chime in, if you read what is being said here carefully, you will understand much better why the "Stenzel" brace does what it says on the tin. In other words, it ensures that the engine on it's rubber mounts moves in the vertical plane only. Thus eliminating the bending moment at the bolted joint where the front mount joins the lugs on the cylinder head. And on the two bolts at that joint. | ||

Drhach |

I could see this being a big deal for clamping forces. But it seems less important for a rubber isolator. Rubber is amorphous and doesn't really care about planes the way a clamped fastener may. Obviously the guy says that there is a (perceived) improvement. Still.... |