| Author | Message | ||

Arry |

I was putting my Uly back together, after some winter maint, and decided to test the interactive ex action. It opened up, as it should, but didn't close quickly, as it should. The motor backed off but left slack in the cable. It seems both the valve, and the cable were a little sticky. I took the muffler off and got a little lube on the valve (muffler needed repaint anyway). Also tried to get some lube in the cable. It feels a lot better but still has more drag, than I would like. I think this is because of all the bends in that cable. I've had trouble getting lube through the cable, I think this is because of all the bends, also. Anyone else have this problem? | ||

Natexlh1000 |

It's a really horrid place to have a cable. You know with the crazy heat and the roadsalt, mud, random grime. It's probably packed with all manner of terrible things. Damn, I didn't even bother to check mine when I had my muffler off last time! I bet mine is worse! Now you're freaking me out  | ||

Sagehawk |

It's all good. I took my cable out of frame when rolled motor after seeing all those bends. Took a nut and placed at muffler mechanisim.while holding valve open , had coworker tack nut to keep it open. No more problem. Deactivated valve with ecmspy. Left motor on top of airbox hooked up anyway as a reminder of one less thing to worry about. Kiss method they call it | ||

Hugie03flhr |

Sagehawk, any noticeable loss of torque or throttle responce when you did that? I've been trying to contact Special Opps for a muffler with better sound and maintain the valve but if this works, I'll do it. | ||

Njloco |

From what I read about it, the valve was strictly for noise pollution. If you keep it open, you might have to do an update on the ECM strictly for performance. | ||

Hugie03flhr |

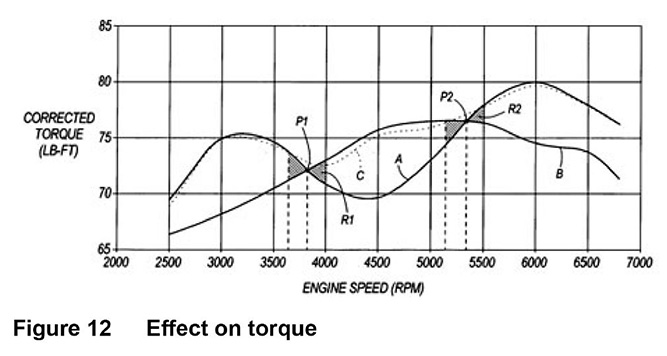

When it first came out I remember Buell touting to helped with the 2500rpm dip that was common on hopped up Harley engines with free flowing exhaust and it had a very strange cycle pattern at full throttle. It opens and closes like 3 times from 1000 rpm to redline. One of the other Buell sites had a nice shootout with all the different exhaust systems on the dyno and special Ops was the most impressive in my opinion because he was able to retain that valve. It really showed up in the low to mid torque numbers and still came very close to the top hp numbers. It was the best of both worlds according to the dyno. I wish I had an idea of what he does to the inside of a stock muffler, I would weld it up myself... | ||

Mark_weiss |

When my exh. valve servo died and I had the valve propped open for a week while I waited for a replacement, the difference was notable. Most especially when negotiating morning rush hour traffic. | ||

Ratbuell |

The valve fights the torque hole in the midrange. It's a noticeable difference when you prop it open or bypass it. There should be a return spring on the muffler, and there is an adjuster ferrule at the airbox to take slack out of the cable. Adjust it like a throttle or clutch cable. | ||

Sagehawk |

Hugie03flhr, there were some changes after motor roll. I had replaced manifold seals, taken and cleaned, greased , hard set tps, .I used ver 2 of spy to bring bike up after 5 months of motor roll. ( life happens somehow and projects don't always get done quickly here), new plugs, wires etc. I no longer have a high idle upon cold start for a coupla minutes and then a drop down in rpm. I had done a multiply by afv the fuel maps after bike was running again and tps, idle set hot. I can't say I've lost anything as I'm not looking for every ounce of performance. It starts every time, idles about 950 until hot and then moves up to 1000 rpm. Bike accelerates hard tthru gears, cruises good, gets around 43 to 47 mpg mostly, and no deceleration popping at all. I just replaced o2 sensor at new years and afv is around 99.9. I can't say I've lost anything from performance. The quirks on cold start I would like to change, but as far as racing ecm, I'm staying with stock until something happens to original. Money's tight, lots of medical with looking at a colon resection, fixing to quit the job I have a and start on closer to home. 500 miles a week for these last few years has gotten old. Anyway, that was too much info but there are reasons I keep the bike as simple as I can. Also with 07, there is not that much resale for it. | ||

Etennuly |

My Uly is an '06. I rode it one time with the air box cover off to see what the actuator does. I was amazed at how often it opens and closes, further, I was intrigued as to when it was actuating. It is like this device is the fine tuner for the flat torque curve on a stock Buell. You have three places torque is good coming from an engine; bottom - middle - top end. "up grading" "tuning" "altering for more noise", etc., can net possibly more torque in one or two of the three. Usually one of the ranges will drop off. From what I have seen this valve set up gets you the best of the three torque range areas available. Tuning for torque is an act in compromise. This muffler exhaust chamber valve arrangement is a real good compensator. | ||

Ratbuell |

It's like when I did concert rigging for a living. There's three types of rigging: Fast Safe Cheap. Clients can pick two. The valve lets you get all three. It's just a fact. Some folks want noise, I'm past that stage of life. Some folks want top end hp, I want a streetable torque curve with no holes. My 06 is bone stock with EBR fueling and it'll stay that way till its done being a motorcycle. | ||

Arry |

Ratbuell, (a couple of posts back) The spring in the muffler should close the valve when the actuator backs off, but because of drag in the cable, and maybe a sticky valve, the actuator would back off faster than the valve was closing. This is why it was leaving slack in the cable. The bike had been sitting for a few months, and I was testing the actuator, without having run the engine. (Hold the throttle open, then turn on the key and "run switch"). This cycles the actuator once, and is when I noticed the problem. After lubing the cable, it still has quite a bit of drag. I guess because of all the bends in that cable. Works OK, now. Just more drag in that cable than would be ideal. (Message edited by arry on April 05, 2017) | ||

Njloco |

I sprayed down the valve with liquid graphite from the outside, I don't know if it will do any good, only time will tell. | ||

Hill90 |

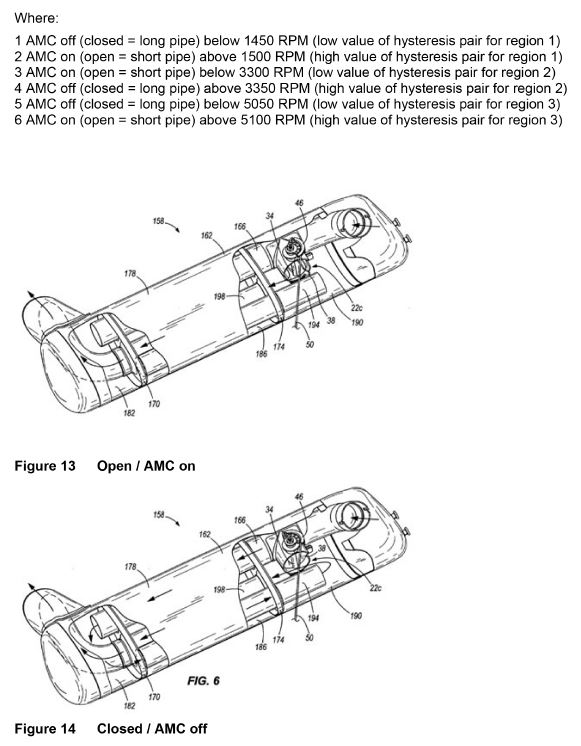

I found this bit of info in the DDFI & DDFI-2 ECM tuning notes showing the operation of the AMC (Automatic Muffler Control). May help to clarify things.   | ||

Hugie03flhr |

Nice chart! Thanks Hill90 |