| Author | Message | ||

Hoover_uly |

Hello all, A couple of buddies and I are planning a bit of a road trip this spring. Two of us will trailer to St. Augustine and meet up with another and ride to Key West and back to St. Augustine. No big rush and no days with a tremendous amount of miles. It will probably be a sightseeing and beverages by the pool in the afternoon kind of trip. However, I want to go over the bike to try and avoid any mechanical issues so far from home. The bike has about 8,500 miles that have been trouble free except for rear wheel bearings, seized rear spark plug and a battery. The rear wheel is off the bike now to replace the tire and drive belt. Belt will become a spare. Bearings are still nice and smooth after about 5,000 miles so I won’t screw with them. Aside from normal maintenance items called out in the repair manual, what else should I be looking for? When I bought the bike, I combed through this site and checked/repaired grounds and the other common failures but feel free to comment. When I removed the right side foot peg assembly, I found 2 of the 3 bolts loose so I will also check every bolt that is accessible on the bike. BTW, I tried to remove the rear wheel and belt using only the Buell tool Kit (the fancy accessory one) and found a few issues like the angled end of an allen wrench was too large to fit in a bolt head and on another, that end was too short to allow movement of the wrench without marring paint or busting knuckles. Going to add a few items to the kit…. So, if you have any information to share from your experiences or stupid mistakes on the road, please do so. Thanks, Steve | ||

Tootal |

With a 2009 model there's really not too much to worry about. I would check that the ecm or the connector to it are not being hit by the seat. If it is you might want to move it. Other than that you should be ok. | ||

Froggy |

You've already checked everything I could think of. Enjoy the trip | ||

Ourdee |

Add a piece of aluminum pipe to use for an extension handle for tools. | ||

Nillaice |

It never hurts to Check your oil level, grease your thoracic coupling and top off the blinker fluid! | ||

Steveford |

Lube the clutch cable and grease the barrel at the lever end. | ||

Njloco |

I would clean off all the grounds, then apply some roller chain lube, do both battery terminals also. Pick up a good tire plug kit. Buy some Ride-On and install in both tires as per instructions. Carry some extra fuse's and extra electrical contacts or whatever they call the boxes that plug into the fuse box, at least on extra light bulb. | ||

Twisteduly |

After playing tech support for a friend 800 miles from home, I have copies of every manual saved on my phone and to the cloud for my 08 and his 07. Saved his ride and made it home. So that's what I would add to the suggestions. | ||

Hoover_uly |

Thanks for all the suggestions. Some stuff I've not thought of. Installed the new tire and belt. It was the first time I installed a new belt. Wow, that was a bitch. It was so tight, it was difficult to screw in the axle even with anti seize applied and the wheel was difficult to turn. Took it back off and drilled out the tensioner holes by about 2mm. Still really tight but it was much easier to screw in the axle and turn the wheel so I left it there. I also noticed that the swingarm seemed to have a lot play from side to side. Couldn't find a spec in the manual other than trouble shooting belt wear which basically said if you have belt wear at an edge, look for bent or worn parts. Since the belt is tracking just fine, I put it all together. Still concerns me a bit. Anyone have any experience with worn swing arm bearings? The bike has about 8,500 miles on it. Thanks again. | ||

Hugie03flhr |

I don't think that swing arm should move left to right at all but hopefully someone else will jump in if I'm wrong. I know I would be a little concerned. I would have also slapped in some new rear brake pads while the wheel was off and also check the front pads. Other than that, check primary chain tension and oil. The rear axle I read the tensioner bolt should be loosens to gain a little slack in the belt. | ||

Brother_in_buells |

If there is play on the swing arm bearings ,you really have to look at that because there has to be no side to side play whatsoever!} | ||

Natexlh1000 |

Yeah there should be no play in that swingarm pivot! Look it over very carefully before riding it again. | ||

Hoover_uly |

Well, it was driving me nuts so I took the swingarm out for a look and it turned out to be a wild goose chase. The pivot shaft is just a bit smaller than the bearing id . My cheap digital micrometer is much more suited to measure the size of the shaft rather than the ID of the bearing so that was a waste of time. Regardless, it is not a tight fit. So, a little slop in both bearings at the pivot is considerably more at the back end of the swingarm. The bearings are tight and turn smoothly so there is no issue there either. The shaft is anodized black and it only has the smallest shiny spots where the bearing rides against it under the load of the belt. I'm calling it good and have no regrets for the time invested. I can't put a price on peace of mind... Thanks for all the responses, it's going back together tomorrow. | ||

Sagehawk |

Grab a cheap voltmeter to include with fuses and maybe a spare relay or two as well. Don't forget that partial roll of camo duct tape as well! | ||

Arry |

Seems a few people have had trouble with new belts, lately. I wonder if some new belts are off spec - a little shorter than they should be. ??? | ||

Ourdee |

| ||

Ourdee |

| ||

Ratbuell |

I picked up a Slime brand air compressor (WalMart, I think) a few years ago. 12v, plugs into the power outlet, it's about the size of an old flip-phone. Not the fastest (I'd never use it on a car tire)...but it works. Just start the bike first! I keep it, a plug kit, and the Buell blue toolkit in the Buell underseat bag. The Buell toolkit DOES do everything needed for a roadside belt change. I've done it - on my 06. So unless something changed, or you have a nonstandard bolt somewhere...you should be able to knock it out no problem. Did it on the shoulder of the road, on the sidestand, in under an hour one day (used spare belt). If you haven't already, put a voltmeter on the bike so you can keep an eye on your system voltage as you ride. Any other method is "too late". Kuryakyn on mine, multi-segment display shows decay intervals. Some folks have color-change LEDs. Whatever your choice...it's vital to have on the bike. After doing something like a tire/belt change, I always paint-dot my fasteners as I torque them. Use something bright - my bikes all have bright orange molten orange touchup paint dots on the fasteners. Dot one side of the fastener head, and the piece it attaches to. That way your pre-flight checks go much faster - dots lined up? Still torqued. Dots moved? CHECK IT. Easy visual check, I paint every bolt as soon as I torque it down. ESPECIALLY far from home, it's nice to know before it's too late that you have a critical fastener moving around on you. | ||

Hugie03flhr |

Hoover, what measurement are you getting at the end of the swing arm? If you are getting .005 to .010 wiggle with little pressure, you may need to put some shims or replace the bearings. I wouldn't let it worry you or stop your trip but things like this only get worse over time. I admit, I don't know if this is normal but on other bikes I've had, it isn't. | ||

Natexlh1000 |

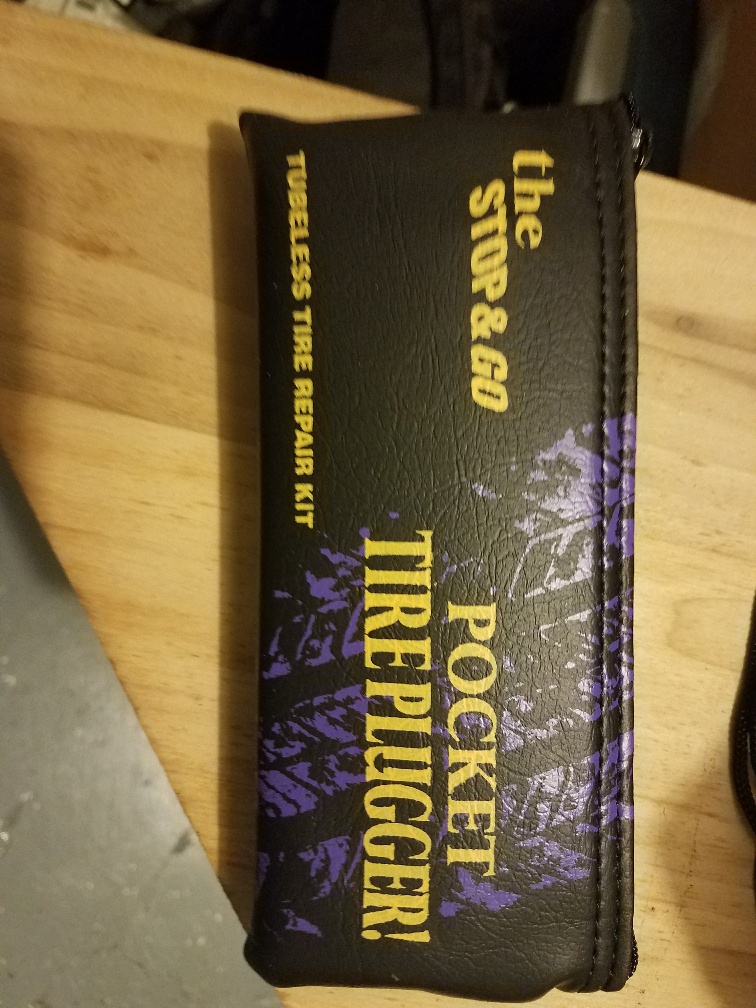

I got one of those stop and go kits too. I suggest trying all of the parts before you trust it on the road. Mine came with the threads poorly tapped/mangled. After that, I used it with great success. Those mushroom plugs work mint. | ||

Tootal |

I like Rat's idea with the paint on the torqued fasteners. One thing is I would do a belt change in your garage with good tools and break the red loctite the factory used. It's too much for the fastener size and is very hard to break loose with the stock tool kit. Use the used belt for a spare and then use blue loctite to assemble everything. This will make that road side repair so much easier because you know it's going to be at night, on a lonely road...in the rain. | ||

Anaconda_jiu_jitsu |

get AAA plus, for motorcycles. also carry 4 cheater straps for the tie downs. peace of mind. | ||

Mark_weiss |

I've found my Ulysses (08) to be highly reliable and relatively trouble free. I take with tools to remove either wheel and a spare belt (because now you can't pick one up just anywhere). Beyond that, my pre-trip prep simply involves washing the bike. Not because it needs to be clean, but because during the cleaning process I take the time to check all of the bike's details and adjustments. | ||

Anaconda_jiu_jitsu |

always mosquito repellant also. ever got stuck on side of road with mosquitos, not fun | ||

Ourdee |

I usually have water, 1/2 gallon of fuel, charged cell phone, and cash. Lucky, the time I lost the wheel bearings. I had iced tea, a foldout chair and a sketch pad. | ||

Ratbuell |

Oh yeah, for people supplies...I have an operators manual tube under each saddlebag. One is an MSR fuel bottle holder; the other has first aid stuff. They live on the bike.  And an edit to my earlier post - upon reflection, I carry the roll-up toolkit; THAT's what I used for the belt change, not the blue factory pouch thing. Sorry! | ||

Ourdee |

upon reflection, I carry the roll-up toolkit +1 My first aid kit has migraine pills and super glue. | ||

Hoover_uly |

Thanks again to all that responded. Lots of good info and suggestions. I will have most of the items suggested along but I cannot locate the thoracic coupling so I guess I will have to wing it there. For the Buell tool kit, it is a good kit but the 3/16 allen will not fit the 3/16 hex head bolts that are stamped HD 8 but another brand 3/16 allen pops right in. The wobble end fits but the other doesn’t. There may be some other issues but they escape me at the moment. Regardless of my experiences, I suggest that anyone that has not done so, attempt to repair their bike with their kit at home before they need it on the road. I will definitely supplement the kit with a few more items. The swingarm is back in. As stated earlier, I did not see or feel any wear on any components. Bearings are tight in the swingarm and turn smoothly. The clearance, or what I can see or feel is between the shaft and the inner bore of the bearing. I did not attempt to measure the play at the end of the swingarm but it was considerably more than .010. This is an odd design in my experience. I am accustomed to a swingarm that has the pivot bearings at the outer edges of the swingarm. On the Uly the bearings are closer to the center of the swingarm. So, any play in the bearings or shaft is multiplied in the front and even more at the rear. Check out the manual for an illustration, Again, yours could be different but I expect that I could spend $100 bucks or so for bearings/shaft/shipping and have the same problem. These are fairly stout bearings. However, installed and torqued, I cannot feel the play I reported earlier but the shaft is liberally coated with anti-seize so this may be temporary result. Perhaps the reason for the play between the shaft and bearing is because there is a possibility for corrosion and since the shaft is only accessible from one side, it could be extremely difficult to get the pivot shaft out if corroded. I remember having to hammer out my severely corroded rear axle when I replaced the original bearings. Of course, I could have it all wrong… A plug kit is a no brainer. I’ve not seen the stop and go kit. I learned my lesson with the original tire with the paper thin carcass. Fortunately, my son was at home, I gave him my coordinates and he showed up about an hour later with the truck and trailer. I’ve carried a kit ever since but only needed it for one of the cars. Someday it will come in handy. I also carry a pump but it is larger than Ratbuell’s. May have a space issue and have to reconsider the brand. Blue locktite on everything. Marking is a good idea. Kuryakyn volt meter is installed but being color blind makes reading it more challenging. Don’t know where I could stow a folding chair but heck, it could come in handy along with skeeter repellent. Thanks again to all. | ||

Ourdee |

Trick to pump size: You do not need the plastic the pump is in, if you don't touch it when running. it gets hot. |