| Author | Message | ||

651lance |

We just did a price book update the other day and just saw that the retail on the front engine iso mounts L1501.02A8 just jumped to $145.80 from $83.74. last time the rear mount L0505.9 was on back order for months retail started at $17.90 and ended at $96.67. I'm not sure if this is the last jump or not. Don't shoot the messenger.  | ||

Nillaice |

is HD price-gouging in an effort to get buell sport-bikes off the road so people buy Harley cruisers instead? | ||

Froggy |

Most likely just supply and demand combined with economics of scale. Harley isn't ordering 10,000 isolators a year anymore, so the cost per unit is going up. I've seen many parts go to 2 or 3 times their original price since mass production ended. | ||

651lance |

This also a new supplier for this part. | ||

Court |

It, more likely, is the reality of producing 100 instead of 10,000. | ||

Teeps |

Not what we wanted to hear, and I don't like it... But, I was expecting just that, a massive price hike. However, it's still cheaper than a new bike. (Message edited by teeps on December 22, 2016) | ||

Livers |

I'd rather have a jacked up price, than have the parts become unobtainium. These parts are typically once in a lifetime replacement - either a long term failure or the bike was wrecked. | ||

Cbig |

I do have an extra isolator if anyone needs it. | ||

Court |

>>>These parts are typically once in a lifetime replacement - It's also one of the few parts that . . if you loose it . . the bike is a paperweight. | ||

1313 |

>>>These parts are typically once in a lifetime replacement - It's also one of the few parts that . . if you loose it . . the bike is a paperweight. And then Redneck's business plan finally comes together... Since their frames don't use the front isolator, everyone will put the powertain in their frames and motor on. Yes, this is just some Christmas humor. I must say that, for a place that discusses politics so damn much, this is a tough crowd...  In all actuality, H-D could've been total pricks and just obsoleted the part. But - as they've proven many times before - if H-D can make money off of it, they'll be there for you.  Cutting through the wisecracks and sarcasm, I'm honestly glad there is a more expensive part available rather than no replacement parts available! 1313 | ||

Njloco |

If apart, use linseed oil, make sure to wipe off excess, if not apart, use a GOOD quality silicone spray. One could easily rebuild them, there are many HIGH quality epoxy rubber products of various durometers out there now, make sure to also get the metal primer, this guarantee's the adhesion to the metal, it must be very clean. (Message edited by njloco on December 23, 2016) | ||

Cbig |

I do have an extra isolator if anyone needs it. | ||

Hughlysses |

These parts are typically once in a lifetime replacement Tell that to Etennuly; I think Vern's been through at least 5 or 6 of them on his Uly, but he was mainly doing fully loaded, two up riding when he was getting frequent failures. I think he hasn't had a failure recently since he's mainly riding solo. I mentioned previously that a guy on the Xboard Buell forum was working on a repair procedure for failed mounts. His first try didn't work out, but that's been a year or so ago. I need to try to find the thread and see if he's come up with a better fix. One could easily rebuild them, there are many HIGH quality epoxy rubber products of various durometers out there now, make sure to also get the metal primer, this guarantee's the adhesion to the metal, it must be very clean. This sounds like the ultimate solution if/when the OEM part becomes unavailable. The trick is to figure out what the appropriate hardness is, and take a cast of the rubber section of a new mount so a duplicate could be made easily. | ||

Court |

>>>One could easily rebuild them, No. One can not EASILY rebuild them. There's quite a bit of engineering in that isolator. I suspect that were the need acute, someone would do it. It would neither be cheap nor easy. Fortunately there is now an ample supply so it's a "non-problem". | ||

Teeps |

Njloco Posted on Friday, December 23, 2016 -<snip> One could easily rebuild them, there are many HIGH quality epoxy rubber products of various durometers out there now <snip> That would be great, if it could be done. However, the front mount is a complicated piece of engineering. And, I doubt that a satisfactory repair could be replicated "at home" with off the shelf RTV or other rubberized products. The best we could hope for is the blue prints for the part appear in the trash at H/D. Are recovered and a vendor is found to build the part, (even if it's only the double bonded rubber bushing.) Another thought I've had is finding an off the shelf automotive suspension bushing with the correct O.D. and I.D. specs that could be pushed into the aluminum bracket. But there would still be vibration problems, probably as bad as a solid mount. (anyone here ever replaced supple suspension bushings for high performance "racing" urethane bushings?) | ||

Njloco |

I'm a relative newbie when it comes to Buells but, I've done what you would consider remarkable things with epoxies however, not to be confused with your store bought epoxies. The hardest phase of making it would be placing the center hole and avoiding air pockets and of coarse getting the closest durometer in the first place. The actual shape might not be necessary, in other words, it will end up being a solid donut with a hole and adhesion to the metal housing. Though very old ( might not get the chemical reaction ) I still have some lying around somewhere and would love to do an experiment if I didn't have a broken right wrist and two broken ribs. | ||

Hughlysses |

I imagine a huge part of the mount's ability to isolate vibration comes from the rubber ribs which isolate the inner sleeve from the outer mount. If you can't come close to duplicating that configuration, I think a rebuilt mount won't be very satisfactory. Thankfully we don't have to worry about that yet. | ||

Hughlysses |

I finally found the thread at BuellXB.com on the guy's re-engineered isolator. It's not a repair, it's actually an all-new assembly: http://www.buellxb.com/forum/showthread.php?51131- Buell-XB-high-performance-front-isolator He actually made an entire new assembly: The cool thing about the design is the rubber (actually polyurethane) inserts are easily replaceable. The builder's post in March 2016 states that his design did a great job isolating vibration, but failed after a short time when the polyurethane tubes began to shear off. He had some ideas for improving its durability (including using stiffer polyurethane tubes) but he hasn't posted any updates since his last post in May 2016. | ||

Njloco |

Well you can easily isolate them, hence the donut with adhesion to the outside housing and the inside sleeve, like I said the hardest part is centering the sleeve. One might be able to inject it in while on the bike we used to do that in certain applications. Understand it still has to be taken off the bike first to set it up. If the sleeve is supposed to sit dead center, then it's real simple. The biggest set back I can see, assuming we have the correct durometer, is the cost effectiveness as these epoxies are not cheap. | ||

Court |

I sent that drawing to an engineer once and got an alarming response. With that . . . I'll leave the conversation comfortable that there is no shortage of supply. | ||

M1combat |

Yeah... I think for a "re-Engineered" solution for a part that was originally done with the financial backing of HD I'd require at least one second opinion and some pretty good evidence to assure me it wasn't going to fail mid-corner on some mountain road somewhere. I mean... An engine mount on most vehicles or even most motorcycles goes south and it's not much of a problem... On the XB... More of a problem. | ||

Chazaag |

Glad its still being made.. I think it is also a good sign that they found a new manufacturer rather than obsoleting the part... $145 - still affordable.... | ||

Teeps |

Chazaag Posted on Sunday, January 01, 2017 - Glad its still being made.. I think it is also a good sign that they found a new manufacturer rather than obsoleting the part... $145 - still affordable.... True. I hope someone can secure the blueprint(s) for Buell specific parts. Before they are destroyed by H/D when they tire of dealing with the Buell brand.} | ||

Hughlysses |

Twin Motorcycles posted on Facebook this morning that they are developing their own front mount for the XB's. Apparently the long lead time for the OEM part has been a pain for them recently as they service a LOT of Buells in Europe. | ||

Teeps |

I will be both surprised and pleased if Twin Moto is able to develop a replacement front mount that works good as the OEM part. Without blueprints and engineering specifications it's not going to be easy... or cheap. | ||

Falloutnl |

Yeah, cheap isn't really a familiar concept to TM, but they make good stuff. | ||

Hughlysses |

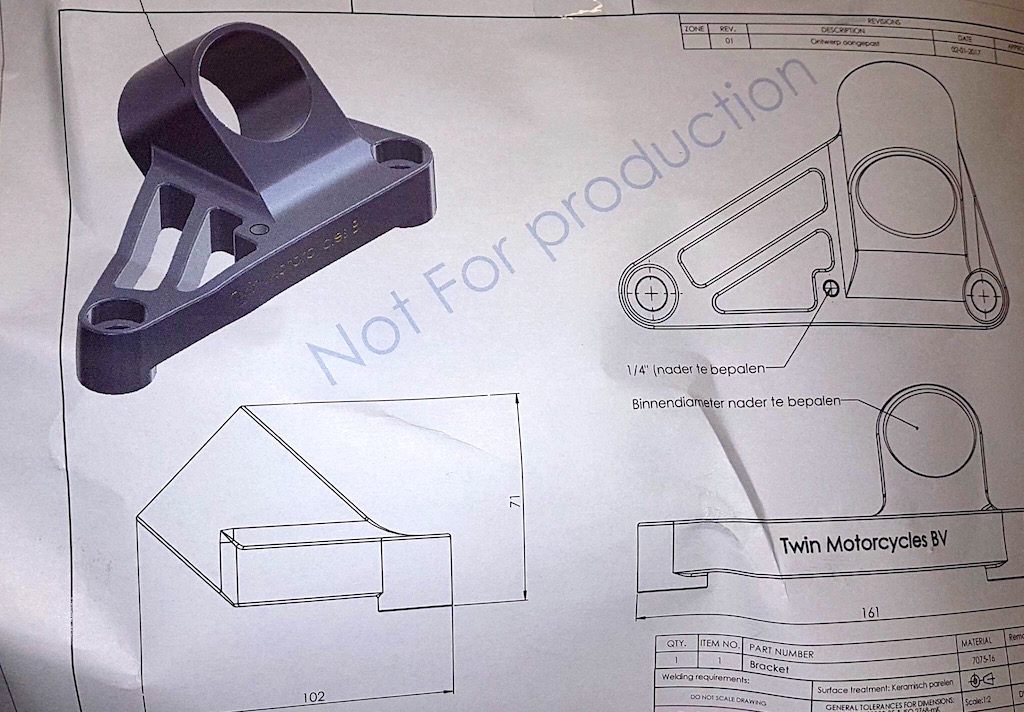

Drawing posted by Twin Motorcycles:  | ||

651lance |

That the easiest part. | ||

Teeps |

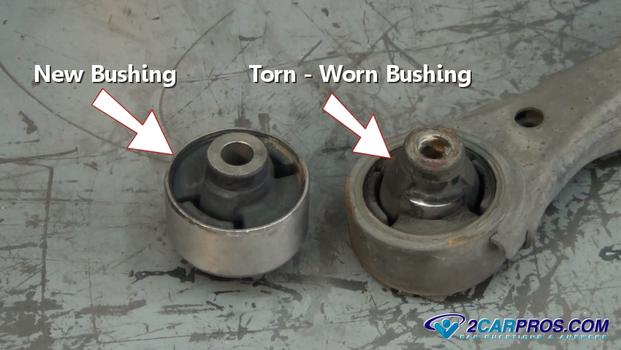

Cool, but the bracket is the easy part, it's the isolator that makes the part functional as a motor mount. I would rather see a replacement isolator developed. Which from what I can determine is a, propriatary, double bonded bushing. Similar to suspension bushings, used, in modern cars. See "new bushing" in photo. There are probably hundreds if not thousands of serviceable brackets out there with bad bushings.  https://www.2carpros.com/articles/lower-control-arm-bushing-replacement Again, I would be thrilled if Twin Moto can reverse engineer the bushing. As was mentioned else where in this post, the bike is a door stop without a serviceable front engine mount. Thus even expensive is better than none... | ||

Falloutnl |

I shall ask about the bushings the next time I'm at their shop. |