| Author | Message | ||

Loose1 |

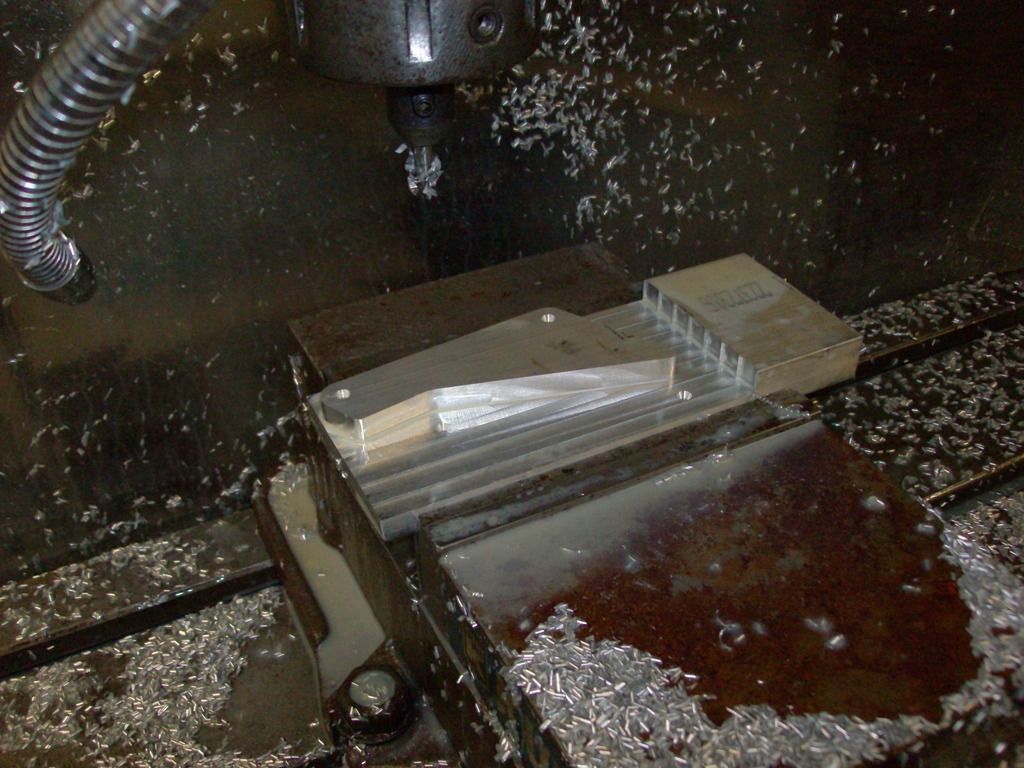

I put that shock on it. It came with a 14" shock on a 16.5 bracket and a extension on the shock. Ralph, I'll do it on my mill with a boring head. I can indicate off of the rotor and pulley bosses to get my location. I'll use 6061 for the sleeve. I did the same thing with a xb wheel last year. Nothing too difficult with the proper equipment. I'll post some pic's Matt | ||

Lornce |

Ralph, I had access to a friend's killer huge lathe when I made my last PM wheel sleeve repair. My buddy has since retired and sold off all his equipment so now I'm looking for access to another to fix my new used PM's. I sweated the sleeve with a 0.003" interference and final cut the bore after the sleeve was shrunk in the hub. fwiw (Message edited by Lornce on November 15, 2016) | ||

Johnod |

So does the 16" or 14" shock get the sleeve? | ||

S1owner |

Matt This is just me asking because I do not know and I am curious? Would it make sense to do the sleeve out of say chromoly? Would it make sense to just use a bigger bearing? | ||

Loose1 |

You could run into issues with using dissimilar metal/alloys. They have different expansion rates and amounts. If I was to use a steel for the sleeve I would be worried about the bearing rusting to the sleeve and pulling out the sleeve when replacing the bearings. I could use a bigger bearing but I like to keep things close to original for the ease of finding parts down the road. When I built my blast people wanted me to use a aftermarket FI system instead of retrofitting a buell one. But what do I do when that system as an issue and the company is no longer in business? With the Buell system I can get parts at the local auto parts store. Matt | ||

1313 |

So does the 16" or 14" shock get the sleeve? The SRP only fits the long Showa shock, but is not required on all tubers. Go, Matt, Go! 1313 | ||

Ralph |

Matt (howdy Lornce), many years ago I tried knurling the wheel to hold the bearing in place. Didn't work, just not enough metal to hold that bearing tightly. I ended up using a friends monster lathe to bore the wheel for the sleeve (great minds think alike, eh Lornce?). But, that's no longer an option. You know, now that I think about it (it's been about fifteen years) I think to indicate the wheel in I used the inner bearing surface (the inners are usually okay). That would be the way to do it for a sleeve - or at least another option. Matt, bi-metal reaction is not a reason to skip steel as a sleeve material. The bearing is steel so you already have steel in contact with the aluminum. Just for the record, I used 6061 for my sleeve. Ken, I can't think of a good reason not to use steel, offhand. I can't really think of a good reason use it either  What I've always wondered about is the set up for the bearings from the get go. As far as I know it is ALWAYS the drive side of the wheel that fails. Evidently, the Buell engineers saw a potential problem and solved it by utilizing two bearings rather than one. But, it seems to me that aggravated the problem. The outer bearing is taking virtually all the load while the inner bearing is just along for the ride. More to the point, the pair of bearings are narrower than the single bearing on the opposite side of the wheel. Wider in tandem, but narrower individually. That means that virtually all the stress is being placed on a single bearing (the outer) that has a comparatively small amount of material in contact with the wheel. So, when the bearing wears and places load on the outer race the wheel material gives and the bearing spins. Yesh, that's to much typing. To finally make my point, I've always wondered about finding a wider bearing or even just simply installing the same bearing as the opposite side. Either way would get more wheel material in contact with the outer race and reduce the possibility of the wheel being trashed by the bearing spinning in it. Or maybe not. | ||

Lornce |

Ralph, I'm not sure about other's experience (obviously) but the PM wheel that got toasted on my old S3 happened very soon after I got the bike. Before I learned things stayed a lot healthier if the drive belt was set nice and loose. I haven't lost a rear wheel bearing since I started running the belts loose. I believe the problem was exacerbated all those years ago by HD techs setting belt tension similarly to a Sportster, which has a completely different pulley centreline to swing arm pivot relationship. fwiw | ||

Ralph |

Lornce, I've always thought of it as a design flaw. I'd never considered belt tension as a contributing factor. That makes a lot of sense. It's also reassuring since it means that failure is avoidable. Sorry for the hijack, Matt! | ||

Loose1 |

Forks are rebuilt and installed. Rear wheel is repaired. Brake adapter is made and ready to be installed. The headlight bucket adjuster holes were damaged, I fixed them. Need to get new adjusters. Faring stay painted. I'm going to make a bag bracket and probably handle bars. Working on designing a new dash. I'm going to take a day this week and clean and reorganize the shop. It's getting to be a hole. Matt      | ||

Johnod |

PM sent re bag mount. | ||

Jolly |

What kind of bags are you planing to use when you design your custom mount? S3 and S2 bags are obsolete.... I have a bag mount for S3 bags on an S2... Buell part #... however S3 bags are... obsolete... I've been contemplating developing a mount system for Hepco Becker journey bags onto an S2...... | ||

Loose1 |

I have S2 bags with narrow lids. My tubing bender will be here next week. Matt | ||

Loose1 |

I got the bag mounts roughed in. Just need to make some tweeks, and finishing. I got my dash mostly done just need to mill the back and assemble it. Matt  | ||

Brother_in_buells |

Wooow that,s beyond awesome!  | ||

Court |

My compliments for using a "#226 correct" Pegasus. That was about the time of the big fight. HD came along and collected all the S2 dash badges with the "real" Pegasus and changed them to the "revised" badges . . . #226 would have been roughly about that time . . . . | ||

Williamscottrobertson |

Court, I was trying to find your write up on the logo debacle in the archives. Would you please link me to it? Id love to read about it. -- William | ||

Court |

I don't think . . . . I ever put anything on Badweb about it. But in the book "25 Years of Buell" we did a sidebar about the S2 badges. I'd slipped one out during La Purga when Harley-Davidson was removing any mention of HARLEY-DAVIDSON on the Buells. They seized the original "Powered by HD" badges and replaced them. They missed 2 HD references on the 1995 S2 Thunderbolt. | ||

Blks1l |

Court my 96 S2 tank has the "Powered by Harley Davidson" stickers on it, were they originally installed on the earlier S2's? | ||

Court |

Are you talking about the tank stickers or the instrument panel medallion? Put a pic up if you can and I'll take a look at it. | ||

Williamscottrobertson |

Thanks court, I ordered a copy of the book. --William | ||

Loose1 |

Got the gauges installed in the new dash. If I was to make it again I'd use a thicker piece of Alu. and make the gauges flush. The bag mounts are almost done too. Work on this project is going to slow with snowmobile racing starting up on the 31st. Matt  | ||

Jolly |

VERY NICE!!! Outstanding job on the dash!!! | ||

Ratbuell |

...I still want one of the unobtanium/forbidden "powered by HD" dash badges... | ||

Johnod |

What are the three gizmos in the top left? | ||

S1owner |

Acc switches maybe lights heated grips? | ||

Loose1 |

Yep, their acc. switches. One is for driving lights and I'm not sure what I'm going to use the other two for. | ||

S1owner |

One could be for a marble droper for those crazy drivers | ||

Blks1l |

Court, here is that tank picture.  | ||

Court |

Thanks. That was added by someone. Thanks . . . I thought i was loosing my mind. There were only 2 references to HD on the 1995 S2. One was on the engine cases and the other eludes me . . . i think it was on the VOES or the module. |