| Author | Message | ||

Xbimmer |

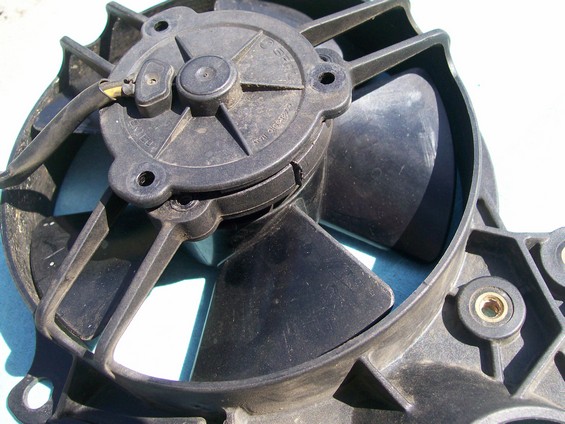

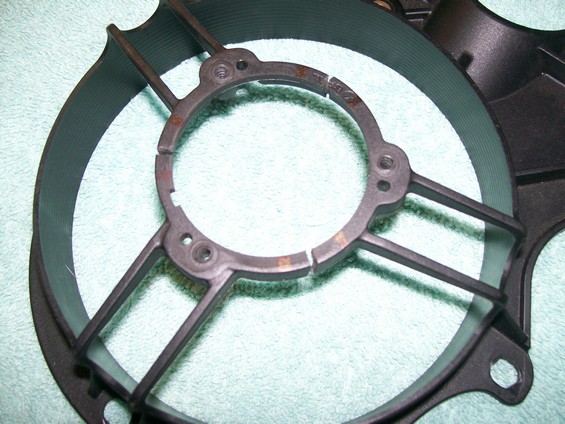

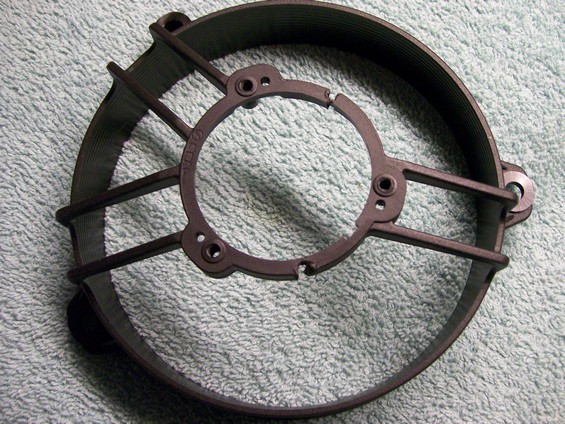

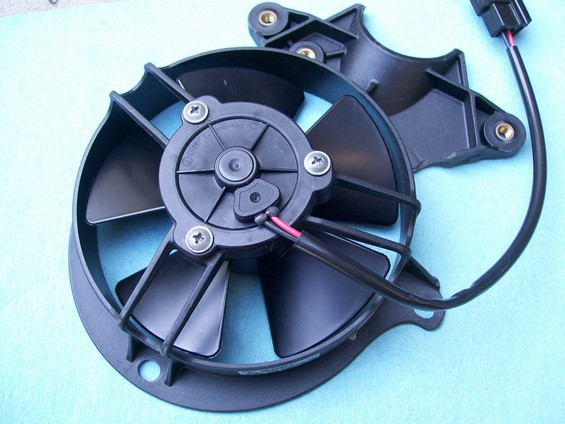

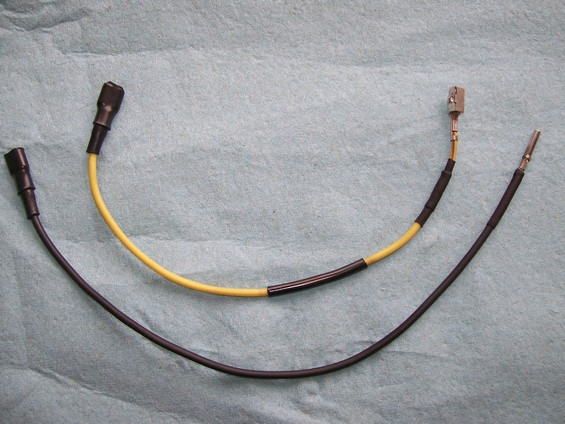

Sooner or later our fans die. Sooner or later HD will pull the plug on XB-specific parts. The idea has been tossed around in the past on suitable replacements for OEM parts, I've been looking into this for a long time and decided to try an alternative to our stock fans. Teeps pointed out long ago a SPAL 5.2" that looked suitable, SPAL has a pretty comprehensive site and I decided that the VA31-A101-46S looked good, the numbers are similar to those on our stock fans and I figured the VA31 part was housing/shroud model. Cheapest one I could find was here http://www.amazon.com/Spal-30103013-Paddle-Blade-Pusher/dp/B009OBP182/ref=sr_1_1?m=A38MU6SGX38CBN&s=merchant-items&ie=UTF8&qid=1431279200&sr=1-1&keywords=spal+5.2 so I bit the bullet and ordered one. Before it arrived I decided to try out my idea first. My first fan died about 50K and was replaced by a '07-built unit, I ran that until a couple years ago then pulled it to keep as a spare and replaced it with a '06-built new one I'd bought when the bike was new. Something not right about those '06 fans because the second one (my 3rd fan) started failing recently. I retrieved the '07 spare and used it as a test mule, removing/reinstalling the motor/fan in the shroud and putting it back into the bike. It's been working great for a few weeks now so I guess my idea is good. Time to "rebuild" the failing (bearings gone) '06 fan. The SPAL replacement:   Seem to match fine:   The longer pigtail will work to my advantage, I intend to build a jumper straight to the ECM:  Here we go. I unscrewed the motor from the shroud so I could move it around for Dremel room:    This is what you're after, 3 cuts through:  The next steps I would only do on a room temp or sun-warmed shroud. I did break one support arm at the shroud on my experimental unit by rushing it. You want the plastic to be flexible and you work patiently and it's no problem. Carefully push the motor housing down at one point and get it started under the shroud ring:  While using the flexibility of all the separated arms, slightly rotate the motor until you can slide it down and out from the shroud:    And out it comes. Next after practicing on the bad one you get to remove the new SPAL from its shroud, same technique but the SPAL shroud is much more flexible so I only made two cuts:  Motor/fans look to be the same except for the lead:  Reverse the procedure and there you are:  I'll post more pics and a performance report once I get this one into the bike. | ||

Electraglider_1997 |

Xbimmer, I'm very interested in what you are doing as I'm sure others are. You've left out much of your thinking about why you have to make cuts instead of just unscrewing the fan from the new unit's shroud for putting into the ULY specific shroud. The only time I've handled the fan on my 06 ULY is when I had to jockey it out of the way to change the O2 sensor. Haven't experienced a fan failure yet but probably am due since I've got 48,000 miles on the original fan. | ||

Hughlysses |

Nice! And at about 1/3 the cost of a stock replacement, right? | ||

Airdale |

Why didn't you just remove the fan blade and unscrew the screws and remove the motor that way? Instead of cutting the motor support housing. | ||

Xbimmer |

Eglider the flange on the motor won't pass through the intact ring, and Airdale I remember Teeps telling me the blades can't be extracted from the motor without damage. I seem to remember an old thread with a disassembled fan mentioning the same. I suppose I could experiment with the failed one, but I wasn't eager to start pulling apart a new $55 fan. Hugh yeah about 1/3 of new OEM, and when finished fan r&r will be easier without that short lead hidden in there. | ||

Electraglider_1997 |

Naturally Buell engineers couldn't of just designed the fan mounts to just use the Spal bracket as is. Xbimmer, I'm hoping you do experiment with one of your shelled units to see if there is a way of taking that fan apart without ruining it. Please take some photos and don't spare the verbiage because I for one like to understand exactly why something was done so that I don't have to ask. Many times things are clear as mud to me. Thanks. | ||

Hughlysses |

Naturally Buell engineers couldn't of just designed the fan mounts to just use the Spal bracket as is. Another approach to using the fan would be to make sort of an adapter plate to bolt to the frame opening; then bolt the standard fan to the adapter. | ||

Electraglider_1997 |

Xbimmer, By the way, thanks for doing this because when my fan decides to give up the ghost I will do as you've done and just buy the fan and reuse the OEM bracket. I don't like paying any more than I have to for anything especially replacement parts for a close to 10 year old bike. | ||

Buewulf |

"Another approach to using the fan would be to make sort of an adapter plate to bolt to the frame opening; then bolt the standard fan to the adapter." 3D printer time! | ||

Uly_man |

This is most excellent work Xbimmer/ Teeps and goes to show that with a little effort (actually a lot I suspect as they have done all the hard research for us) there is no reason to worry about keeping these bikes on the road for many a year to come. You do, of course, have to make some effort yourself to benefit from these guys input. People need to understand that modern bikes/ cars are NOT made the way they used to be. Many parts are "out sourced to a build specification" and then fitted in the factory on the production line. A classic example of this is that three of my past/ present bikes IE MZ Baghira, Buell XB12X and Aprilia RSV-R all use the the same Italian made ZADI steering ignition/ lock system. It is a modular system and used on many bikes and scooters on the market today. Someone tried to steal my MZ and damaged the lock. I replaced it with a used, same as, part from a Aprilia RS125 for $15, inc shipping, off of E-Bay. Nice. Thanks again guys for your efforts. It is something I will keep in mind for future reference. | ||

Nillaice |

GENIUS!!! | ||

Motorfish |

Great job! Thanks for the time, research and effort. | ||

Xbimmer |

You're welcome and thanks for the compliments guys. My original thought was to build an adapter. Then I thought to cut up the original shroud and use it as an adapter. Once I started looking closely at how strong the plastic is, I figured the arms would still offer plenty of support after the cuts since the flange on the motor ties them all together again. I suppose one could ensure a semi permanent tie with some high temp silicone seal under the flange also. If you look at pic 9 you'll see the marks on the ring of Teeps's loaner. Those are from my original idea to leave gaps big enough to rotate the motor flange and simply drop it through. I decided instead to try the single cuts first, it works fine and leaves more support area under the flange. Easy job guys with some care and patience and leaves you money to spend on other things you need. Teeps you can have your loaner back, thanks!  | ||

Big_island_rider |

| ||

Teeps |

Thanks Xbimmer & guys. I got as far as finding the fan, but didn't have an extra $50 (or the immediate need) to go the next step. After some in person discussion on the project, with Dean. He, took the leap of faith for trying to adapt the off the shelf fan. My original thought was to attach the off the shelf fan, as is, to the Buell bracket. Dean's solution is simple (why didn't I think of that?) and makes better sense. I have removed the fan from a couple of Buell fan motors, the outcome is not pretty or reusable. They are crimped to the shaft, so it is not a serviceable part. And even if the fan could be removed and reinstalled. I would be concerned about balance and run out of the blade if reinstalled. I think everyone should bookmark this post. (Message edited by teeps on May 12, 2015) | ||

Nillaice |

could it be added as a sticky to the BBD board? and then ... once amazon sells out of the available stock of these SPAL fans, these 'pearls can be thrown to the swine' and add the sticky to the XBoard  | ||

Djohnk |

Thanks for the how-to, I will remember this post if I ever need a new fan. | ||

Teeps |

For the curious here is what the inside of my Uly's fan motor looked like. Note: it was dry... Commutator wear  front & back side of fan blade: note the 5 point crimp stamp on the front side of the blade.   The blade side bearing was seized, for many many hours of operation. The step in the shaft is wear!  | ||

Teeps |

I suspect that early failures are due to imbalance of the fan blade. Either from manufacture or more likely debris that makes it's way and sticks to the blade... It wouldn't take much weight to cause imbalance problem considering the fan blade speed. | ||

Hughlysses |

There were a few fan failures in the early days of Ulydom (2005/2006) and at that time, we were pretty sure it was due to bearings/lube failing from high temperatures. One Uly owner actually measured temperatures, determined the temp limits of the factory lube, etc. and was pretty confident this was the cause. (You can find the thread if you're interested.) We guessed that later fans had uprated lubricant because failures seem to be much rarer now. | ||

Odjoe |

thanx for the info | ||

L84dinr |

Thanks a bunch for this Info. Great work. Raymond | ||

Xbimmer |

Update. Found the time today to install the new fan mod. The test mule I've been running works but sometimes runs slowly which come to think of it is probably the reason I replaced it before. The new SPAL/Buell combo works great, it's in the high 80's today and it's been cycling as it should and shutting down when it needs to. I'll post some pics of the way I connected it as soon as I find my camera cord... | ||

Xbimmer |

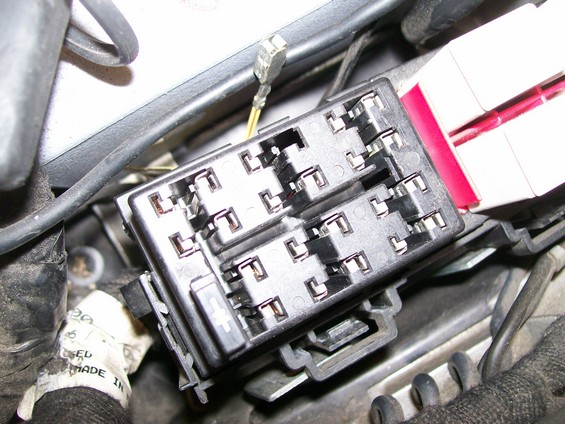

I wanted to take advantage of the SPAL's long lead so I built some pigtails to bypass the stock harness:   R&R'ing my fans is easier since I relieved the frames:  You can see the larger gaps I cut in the ring of my test fan on the right and where I snapped an arm rushing it before, but it still remained strong with no issues the last several weeks:  I rotated the new motor ccw to get the lead to the top:  This is where I like to start the install, for those who haven't done this before:  Fan's in, turned my attention to the fuse box. Took my time and eventually got the yellow/brown fan power connector out. I dislike making things irreversible but the local dealer had no connector terminals so I cut this one away to use for my pigtail:  You can see the tang in there that will snap back into the terminal when replaced:  Snapped the fuse box all together, plugged in my leads. The black lead from the fan plugs into socket #6 on the gray ECM plug, easy to do. Done, and it works great:  | ||

Etennuly |

I have a question for the fan logic scientists.....Is this SPAL unit an actual multi speed fan? I recall my original '06 fan running at a low speed and a high speed per ECM control. Would this not mean that the low speed runs on a lower voltage/amperage? If so could that not cause arcing that could use up the commutator brushes and shaft? Just curious, I have been running my Buell warranty replacement fan on a manual switch only "on all of the time", and only in "high speed" mode for many years. Somehow I feel that the low speed starting/ arcing as well as the frequent on/off electric motor load spike arcing is a possible cause of "Uly fan death". The ECM turns the fan on and off, and between low and high, possibly hundreds of times in a long ride day. Mine only turns on and off once per ride. These are the ramblings of a simple bodyman/painter who has had to change the start contacts on two bigger electric motors so far this year, one on my shop air compressor, the other on a pool pump motor. Both of these motors have very frequent on/off cycles and were otherwise in good shape. | ||

Teeps |

Etenn, Fan speed is controlled by the ECM, via a duty cycle on the ground circuit. I did the "Etenn" fan switch mod on my bike not long after you posted the mod. However, I left the fan wired to the ECM. So the fan still runs after the ignition is turned off. What I discovered when running the fan via switched (bypassed ecm) path to ground is no more premature skip spark! One drawback of this is the check engine is on when the fan is run bypassed. Since doing the "Etenn" fan mod, my Ulysses has only skip sparked one time. That was going up Mount Baldy with ambient temp in the 90s(f.) | ||

Hughlysses |

I have a question for the fan logic scientists.....Is this SPAL unit an actual multi speed fan? It only has 2 wires, so I'd say it's just a single-speed motor. It's a DC permanent magnet motor, so the speed is proportional to the voltage- the more volts you put to it, the faster it runs, within reason. It's probably rated for a certain RPM at 12V DC. I don't think operating it at low speed/reduced voltage would make the arcing any worse. Frequent starts might be the culprit. That commutator does look pretty rough. I wonder how much of the brushes had worn away? Then again, I'm a mechanical engineer, so I'll defer to anyone with more experience keeping the smoke inside the wires and components. | ||

Uly_man |

Both the 06 and 08 fans are two wires and the speed is controlled via the ECM. The 06 bikes run two speeds a lot but the later bikes seem, or my 10 bike anyway, to run at low speed only but I guess it would run at high speed if needed. Mine has yet to do so but then again it never runs as hot as my 06 bike did. That thing was like a furnace. The fan is not in a good place for heat and the bearings/ commutator will suffer over time. Dirty blades from oil contamination, etc will damage the bearings as it will become out of balance. | ||

Teeps |

Hugh, If you're speaking to the photos, above, of my Uly's fan motor. The brushes were worn to the point that they no longer made contact with the commutator, when the axle was askew (at rest) from the wear on it. I was on a ride on a warm day and the fan did not run when I switched the ignition off. Puzzled at that, I switched on the bypass circuit and the fan still did not run. Further puzzled I banged on the frame with my hand a few times, and the fan came on... sounding more sickly than ever. It was at that moment that I decided it was time for a new one. Not long after replacing the fan, did I find the Spal fan that is subject of this post. Dean volunteered to be the guinea pig on the adaptation of this off the shelf fan to the Ulysses installation. A big success for Dean and Buell XB owners everywhere, and a bid saving of money, too boot! | ||

Etennuly |

Teeps, so in reality your fan motor was literally worn out. Not a bearing failure. This is what I suspected my original one did also, but it was replaced under warranty so I did not get to do a forensic exam on it. |