| Author | Message | ||

Upaero |

Hello everyone. Today has taken a turn for the worse for me. I have a 2009 1125CR with 13K miles, KEDA RT3, Race ECM, Twin Motorcycles intake stacks, Mobil 1 20W50 V-Twin Oil (I was just switching to 10W40 since I found out that's what these engines were actually designed for) and K&N air filter. I bought it stock with about 4500 miles on it and have taken to it about seven track days including one a week ago. The other day I started to notice what I thought was a bit of a knocking sound at idle, but wasn't real sure because the exhaust is so loud. It seemed to run fine too. Well, today I do an oil change and see a big sliver of metal on the drain plug plus colorful bits and sparklies on the oil filter. Bad news! This seems terminal and am now searching for solutions. I have the following questions: The big sliver piece is steel so I assume it's part of an engine bearing. Could is also be from the transmission? I don't always use my clutch (but I do let off throttle) on the upshifts during track days and am wondering if that could have caused a failure. Shouldn't these engines be able to withstand the occasional track day better than this? What are my options for getting the rebuild parts? At this point I would really like to go with the 1190 kit that EBR had. Does anybody know if I could get my hands on one of those now that EBR is done? Another option is to just swap it with a used engine I found for $1000 with 9K miles, but I know the risks involved with that. Either way, what should I do to prevent this from happening again? Of course I don't want to stop going to the track. That's that main reason I bought this bike. Any helpful suggestions and/or insight is greatly appreciated. Dave Boynton Beach, FL  | ||

Panshovevo |

I would check the oil pressure before I assumed the engine bearings are bad. This is a plain bearing engine (far as I know), and if the bearing clearance is out of spec, the oil pressure should be low. I wouldn't expect to see a piece of ferrous metal like that from an engine bearing. Not sure where that might have come from. Did you check the screen? This is one of the reasons I don't care for common sump drive trains...when you find metal, it's hard to determine where it came from. Hopefully, someone with more 1125 experience than I can be of more assistance, but I wouldn't jump to the conclusion the engine is failing. Edited to ask how you determined the engine was designed for 10W-40 oil? (Message edited by Panshovevo on June 19, 2015) | ||

Upaero |

I didn't get an oil light, but it probably has to be close to zero for that to happen. If I put oil in and run it does the ECM show oil pressure via usb cable, or would I have to put a pressure gauge somewhere? I didn't know about the screen until now. Thanks for enlightening me. What I found there is whole array of parts. Orange, green and some metal. It keeps getting uglier...  | ||

Reepicheep |

So sorry. Dang. | ||

Shawns |

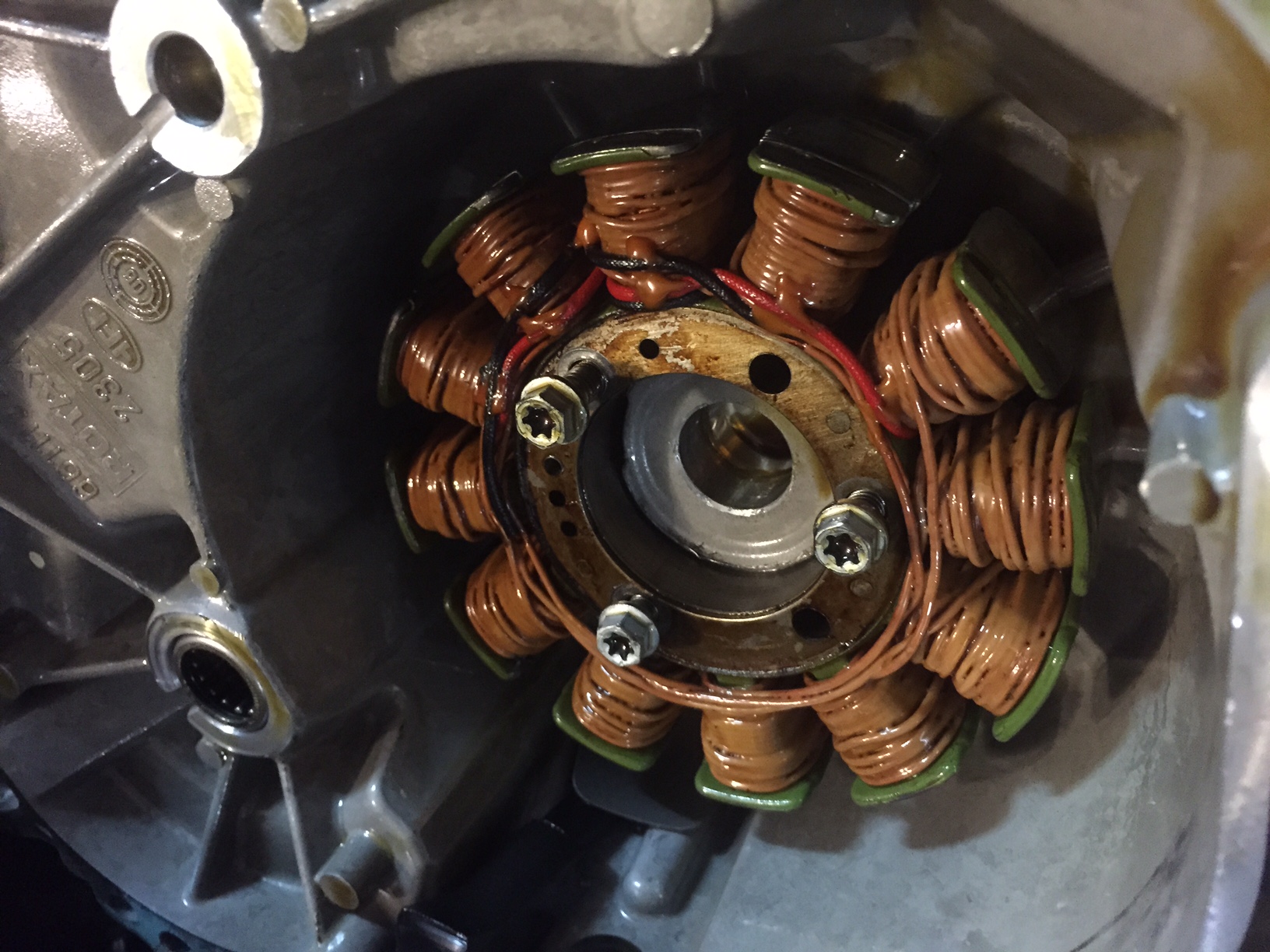

Does this look familiar?   If so, my rotor nut came loose and ended up looking like this  | ||

Dennis_c |

could that be a lot of stator parts? I would look there first with no better idea I do know that there is thin metal part on the rotor | ||

Dennis_c |

Shawns rotor you can see the thin metal part I was talking about | ||

Shawns |

Most of it may be the epoxy that joins the 2 pieces of the rotor together. I was really worried when I found pieces in mine. It took another 1000 miles or so before it came apart. I pulled both sides off and at that time it wasn't evident. Lets put it this way, our bikes are noisy when this happened it was really noisy. In a way, I hope this is your issue not a sign of major damage. It's easy to pull the cover off and give it a look. (Message edited by Shawns on June 19, 2015) | ||

Upaero |

You saved my day Shawn! I took the cover off and found that the rotor was tight, but the three bolts holding the stator were almost ready to fall out. That caused the rubbing of the two. The stator looks pretty good considering. The rotor doesn't look great, but I am comfortable running with it for now, especially since it is an EBR rotor. It looks like my motor will be ok and that I was jumping to conclusions. I think I will put oil in, run it for a bit and then drain to try and flush out any remaining bits. I still would like to know if I could get my hands on an 1190 kit from the EBR inventory. Does anybody know what's going on with that situation? Is somebody currently liquidating the assets?   | ||

Shawns |

I myself wouldn't run it that way. All you need is for one of those magnets to work free or another piece to get free. You might be able to sand it down a bit and coat the surface with an epoxy. I wonder if you could powder coat it or some thing along that line to seal it up. At least my experience with this was able to be beneficial for another Bueller. Odd that you didn't get voltage error.  (Message edited by Shawns on June 19, 2015) | ||

Upaero |

Yeah, it is ugly. I'm wondering if I could get a thin coat of JB Weld to adhere to the surface after sanding it. Of course, then I run the risk of the repair failing and going all over the place too. This has been an enlightening experience. When I thought I had a failed engine I couldn't easily find sources for rebuild kits, or any new internal parts for that matter online. Is HD the only source in the USA now that EBR has closed it's doors? I was really leaning toward a used engine since it seemed like the only viable option. | ||

Shawns |

The epoxy that holds the 2 together seems tough enough. I would gather if you ruff up the surface to give better adhesion you'd be ok. | ||

Panshovevo |

Dave, one of your questions never got answered. If I was going to check the oil pressure on my engine, I would remove the pressure switch and put a tee in the hole. Put the switch in one side of the tee, and hook up a gauge to the other side. In other words, to my knowledge, the factory switch is just that, an on/off switch that is activated by some preset pressure. If anyone has contradictory knowledge, feel free to educate me. PM sent. (Message edited by Panshovevo on June 27, 2015) |