| Author |

Message |

Teeps

| | Posted on Sunday, February 08, 2015 - 02:33 pm: |

|

53 ECM failure is most likely caused by cracked solder joint on the ECM PCB. And, most likely the cause of the other codes and the bike's running problem....

Cut that sucker open, repair the cracked solder joints.

Relocate the ECM.

Then clear the DTCs and retest for the problem.

This thread: http://www.badweatherbikers.com/buell/messages/142 838/673617.html?1333122196

used to have more photos showing more cracked solder details, but you can get the idea... |

Screamer

| | Posted on Sunday, February 08, 2015 - 06:45 pm: |

|

You may want to check to be sure the "seat bumper" block is installed - mounts on one of the ECM mounting screws. If it's missing you may have contact between the seat and one of the ECM connectors which could damage the ECM. |

4sons5678

| | Posted on Sunday, February 08, 2015 - 07:00 pm: |

|

I have moved the ECM as a starting point, like I alluded to earlier, at this point it's a see if the problem happens again type of situation because as it stands right now, short ride and close to home the bike performs phenomenally. One possible solution at a time. I appreciate all the suggestions and tips, I am a previous buell owner of a Daytona thunder race made legal in California Xb and this website was huge in helping then as it is now. Thanks a bundle

(Message edited by 4sons5678 on February 08, 2015) |

Fotoguzzi

| | Posted on Sunday, February 08, 2015 - 07:30 pm: |

|

shot of seat bumper,

|

Steveford

| | Posted on Sunday, February 08, 2015 - 07:51 pm: |

|

there is slight hairline crack on the female connector at the base

You found your problem, all right.

It'll run fine until the bike gets hot and then it'll shut off the fuel pump amongst other things. |

4sons5678

| | Posted on Sunday, February 08, 2015 - 07:59 pm: |

|

Notice the altered metal tab of the battery tray, and the piece I removed where the spacer you speak of used to mount.

ECM mounted 3/4" lower and closer to the space in the subframe hopefully catching the air it needs to stay cool if heat getting to it is an issue (Steve).possible fixes to reveal it would be appreciated. No spacer needed, tons of clearance. And no it doesn't contact or is it hampered by the coil that appears so close :-) |

Reepicheep

| | Posted on Sunday, February 08, 2015 - 09:59 pm: |

|

The heat isn't the problem, it's the mechanical load on the connectors and wires that cracks the solder joints.

It has been successfully repaired before by others, you have to dig out the potting and resolder all the pins.

It might have been relocated by the previous owner *after* it was found to be cracked and problematic. |

4sons5678

| | Posted on Sunday, February 08, 2015 - 10:17 pm: |

|

No no, I have done the discovering of the cracks and relocated it earlier today. The previous owner sold a flawless bike with no issues :-) I am not naive to 'most' (<-----disclaimer lol) buells having some gremlins to chase down, the nature of fun it is! |

Steveford

| | Posted on Sunday, February 08, 2015 - 11:00 pm: |

|

The heat brings the issue to light, so to speak. I've got a cracked ECM and I can ride all Winter with no problem but as soon as the weather hits 60 degrees out things get hot enough under the seat to make the damned thing conk out after about 20 miles.

A couple of good raps with my knuckles gets me going again.

A new ECM is in order before the riding season hits. |

Reepicheep

| | Posted on Monday, February 09, 2015 - 09:24 am: |

|

If it were me, based on what I could gather from this thread, this would be my schedule for next weekend:

1) Remove ECM, carefully pick out potting to get down to the solder joints for the ECM connection, and reflow the solder on them.

2) Dissect the wiring harness where it goes under the steering head and run each wire through my fingers feeling for internal cracks in the conductors. Splice in any wires that seem stressed. Make sure other farkles stuffed under flyscreen aren't stealing "float room" from that wire harness when bars are at either end of a lock to lock sweep of bars.

3) Put a $79 digital scope on the CPS output (signal picked up right at the ECM, don't need to do anything but remove seat and put a paperclip into the back of the right wire on the ECM connector. Watch it as the engine gets hot and see if you are "missing teeth".

Step 3 is perhaps a bit much if you find obvious damage in steps 1 or 2. If you don't mind rolling the dice a little, you can just ride for a while and see if the problem is gone. But it's also really cool to do and a great excuse to buy a $79 digital storage oscilloscope.  |

4sons5678

| | Posted on Saturday, February 14, 2015 - 08:34 pm: |

|

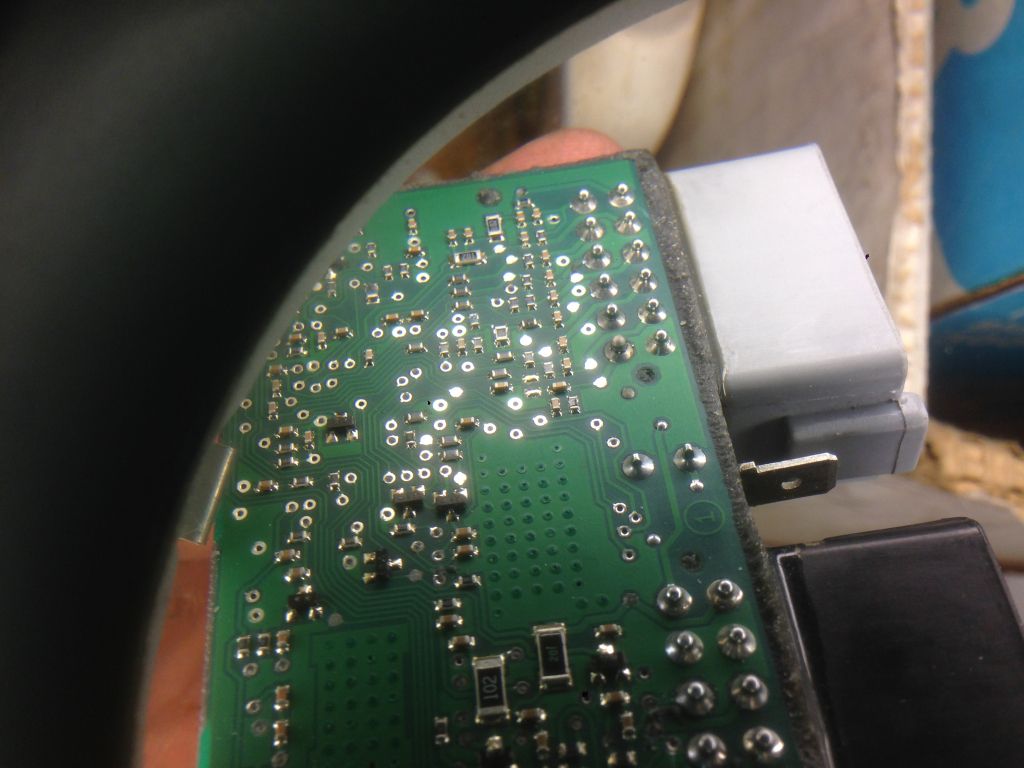

Ok, so Tuesday I rode to work in the chilly morning, no issues. Home in the afternoon, not so much! It didn't quite stutter as bad but I did move the ECM so I figured it was an improvement but next on the list was CPS! A mile from the house, blammo, same set of crappy circumstances as before except, it never threw a code light or did it die. So here, (disclaimer, thanks to all) you may get nine guys who potentially know nine problems for the circumstances you are experiencing, so I was wadded up about what to try next. Hell, I'm going for it, fein tool from the shelf, feel a ECM under your blade, the results

Notice the very visible cold solder joint that is also noticeably cracked all the way around the pins circumference. As well as hairline cracks on several others.

This is where she lay, lowered with a makeover!

I'm happy to report I have had no issues since I cracked her open and re-flowed all 24 pins. The bike is running great with extensive tests under way! It was 76 degrees today. Thanks for all the tips guys.

~ride slow and thoughtful~ :-) |

Reepicheep

| | Posted on Sunday, February 15, 2015 - 12:32 am: |

|

Nice work! And good advice. |

Teeps

| | Posted on Sunday, February 15, 2015 - 10:28 am: |

|

You're welcome 4sons5678.

What is your secret for getting the pcb so clean? |

4sons5678

| | Posted on Sunday, February 15, 2015 - 11:26 am: |

|

No secret, the potting peeled right off! Of course I didn't just slice a notch in the case to reveal the problem area. I removed it entirely from the case (it just worked out that way) there wasn't a plan going in. Im incredibly stoked to have solved the issue, it brings a sense of triumph to realize i got a great low mileage bike for such a good price. AND ITS A ULY, ARE YOU KIDDING ME, MY ALL TIME WANT ONE :-)

~just go slow and don't be stupid~ :-)

(Message edited by 4sons5678 on February 15, 2015)

(Message edited by 4sons5678 on February 15, 2015) |

Teeps

| | Posted on Sunday, February 15, 2015 - 05:46 pm: |

|

No problem, did mine a couple of years ago.

The potting was seriously adhered to the pcb, on my Uly's ECU. The stuff came off in pieces not much bigger than large sand grains...

This is one of the more triumphant repairs, considering the cost of a new ECM. Though, many have reported a much better running engine with the EBR Race Ecm. |

|