| Author | Message | ||

Lospice1 |

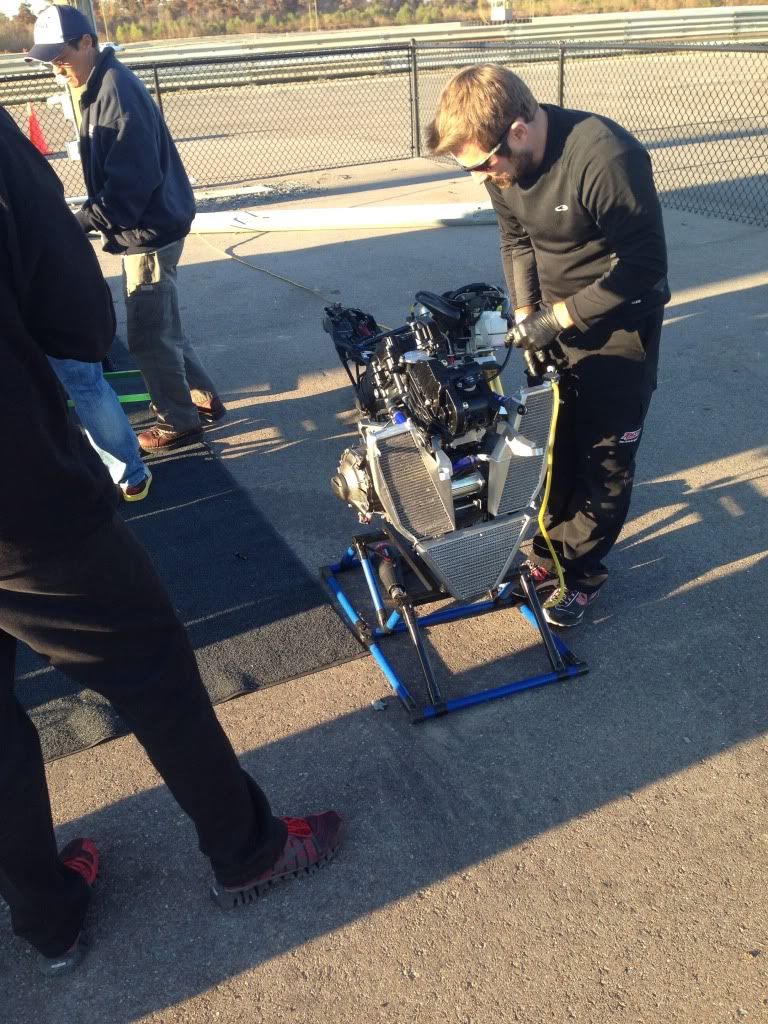

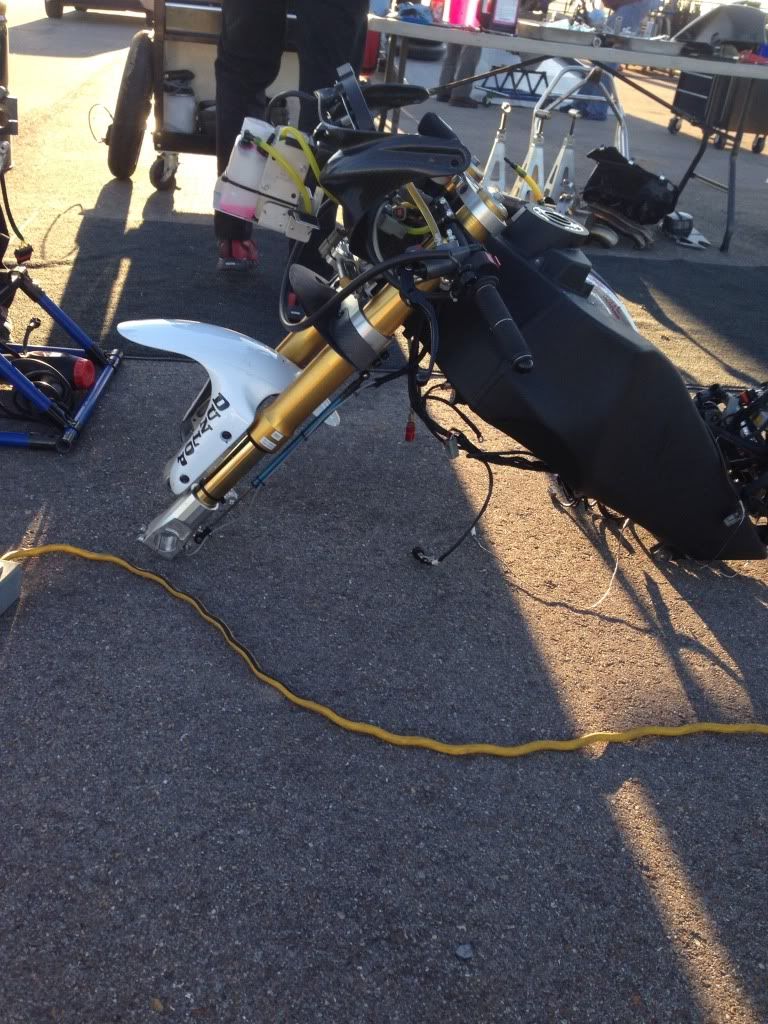

I was at a member's track day at NOLA motorsports a couple of weeks ago and to my surprise Blake Young and the EBR Hero crew were testing! Whats-more, Larry Pegram was testing as well...It was fun to be on the track with those guys and validated what I already knew...they are in a different league! Truly great to follow them..albeit for a nanosecond  Of course I forgot my go pro, but was able to take some crew pics! My attempt at being artistic:       | ||

Lospice1 |

Goody table:      | ||

Firemanjim |

I like that way of working on the motor! | ||

Dannybuell |

that front tire close up is poster grade!!! | ||

Shawns |

Awesome | ||

Mackja |

Pegram keeps denying he is riding an EBR this year. Strange to be testing in January on a bike you are not going to race? Time will tell. | ||

Trojan |

Did they do any testing or spend the entire time bike building? That does not look like trackside fine tuning to me! | ||

Hootowl |

Neat to see all the tidbits that are normally hidden or otherwise obfuscated by body work. | ||

Reepicheep |

While the bike looks really taken apart, the "table of parts" doesn't look that daunting. Maybe a company that is building street legal track bikes built a machine that is really easy to take down to an exposed motor, particularly when it is in race trim. | ||

Hootowl |

What you don't see is the blindfolded mechanic field stripping the bike while his buddies hold the stopwatch. This is my motorcycle, this is my gun... | ||

Jdugger |

The only thing that makes motorcycles complicated in street crap. In race trim, the 1125r was easy to service, too. I could pull the chassis off the motor in about an hour, leaving cooling system and other bits in place. When you get the wiring harness down to just what's necessary, eliminate all the superfluous EPA crap, and it's just a bike... they are refreshingly uncomplicated. | ||

Rodrob |

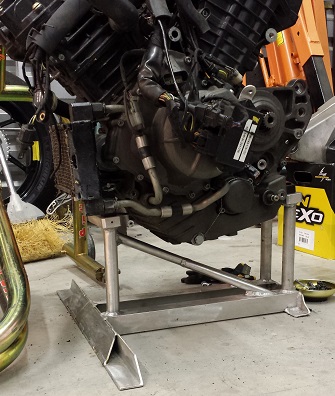

Great pics. Especially interesting for an 1190RS owner/racer. The air box assembly is not the same as my 1190RS. My guess is that it is from the new 1190RX. I wonder if they are using the the RX heads and/or throttle bodies, if they are any different. I've been trying to get one of those engine stands since I bought the bike. no luck so far. This is what I made for the time being.  | ||

Two_seasons |

Those engine stands are made from the same material that GE uses to mock-up and build working kits for the production lines inside our factories. I could find out the material for you and the attaching black interlocks if you are interested. Let me know! | ||

Smoke4ndmears |

There is probably a small market here for those stands. Would love one myself. Thanks for the pics! | ||

Hybridmomentspass |

Im wondering if Pegram was just doing some riding on the bikes for fun like other riders have in the past? I'd love to see him on an EBR though! | ||

Blake |

Nice photos! | ||

Lospice1 |

Thought y'all would like them...It was interesting talking to the crew...they said a lot of parts were being absconded by the WSB team! will | ||

Ron47 |

Did you ask them to do a quick valve adjustment for you? I mean, they already had their tools out and all. :-) | ||

Jdugger |

> There is probably a small market here for those stands. Would love one myself. Something like this?  I could make more, but they would be quite expensive, somewhere in the $350 range. Hand-fabricated, TIG welded construction out of Aluminum. I use mine a lot. So many jobs on this bike are made so easy with a good motor stand. | ||

Rodrob |

I could find out the material for you and the attaching black interlocks if you are interested. Thanks. I believe that they use this system - http://www.americanpropipe.com I have confirmed that I can order the components needed. What I would need from EBR, or somebody, is the custom made top section,upon which the motor sits. Everyone who works on an 1125R or 1190RS or 1190RX, needs one of these. Nice Work Jim! I wish I had that capability. | ||

Vtpeg |

What are the red dots on the brake rotor? | ||

Craigg |

"Pegram keeps denying he is riding an EBR this year. Strange to be testing in January on a bike you are not going to race? Time will tell." There is an article out that EBR isn't participating in AMA this year. | ||

Mackja |

While I know EBR Hero is not participating in the AMA, I a sure Erik would like to have privateers on his bikes. RSR Racecraft, Pegram Racing, etc... | ||

Stirz007 |

What are the red dots on the brake rotor? Maybe heat-sensitive paint (?) to see if rotors are getting above a certain temp. The blue sticker on the caliper appears to be for that purpose. Or it could be just to keep track of what rotors were on which bike for post-mortems. | ||

Dhays1775 |

Stirz, if you look at the edge of the red dot, closest to the edge of the pads, you can see that the color is more yellow than red. I think your on to something...  | ||

Jdugger |

> Maybe heat-sensitive paint (?) That's my guess, too. I have a whole box of heat-sensitive "crayons" here. It's something of a waxy/greasy substance. The different colors are for different temps. They are meant to use with welding prep. You mark the piece of metal and then pre-heat around it until the crayon melts, then you know you are good to go. If one were studying heat dissipation at the track instead of on the brake dyno, this would be a way to take consistent measurements and see if a change were happening. That said, the picture above seems to show "stock" steel hardware. I need a picture looking down into the drive bushings to tell if there's anything unique about it. | ||

Hybridmomentspass |

Or maybe they mark with the paint after its torqued down, so they know they did it wouldnt want THE front brake rotor coming off in a race or testing situation. Maybe. | ||

Hughlysses |

Pegram keeps denying he is riding an EBR this year. Strange to be testing in January on a bike you are not going to race? Time will tell. In the quote I saw (on Stuporbikeplanet), Pegram said he is not riding a BUELL this year: http://www.superbikeplanet.com/2014/Jan/140106a72.htm He may have been being cleverly 100% accurate in his statement. (Message edited by Hughlysses on January 11, 2014) | ||

Riohondohank |

Actually there were 3 riders testing at NOLA for EBR. | ||

Two_seasons |

As Hybridmomentspass said, those red marks at the rotor mounting bolts are probably to indicate they were torqued. Did you know that Loctite removes that torque paint? |