| Author | Message | ||

Spiderman |

No one has mentioned this an I think It may explain a little bit. Jersey, You said you Polished the stack right?? Smooth air flow would not mix the fuel an Air as well as turbulant air flow. Now I bet if you were to add some vortex generators in that stack I bet you would gain a few ponies. Or at the least a better, more efficent burn. | ||

Jerseyguy |

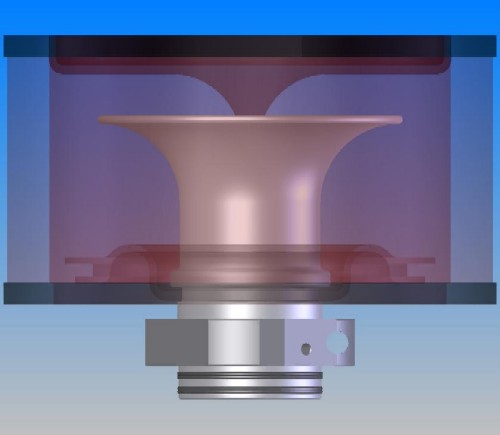

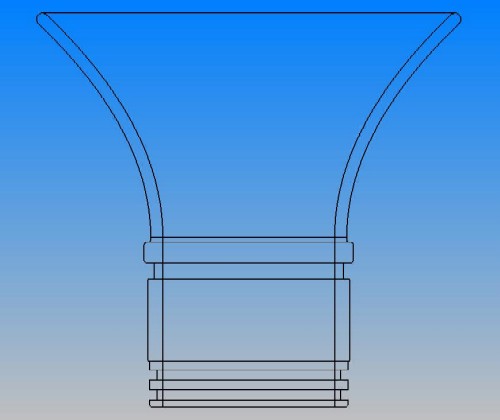

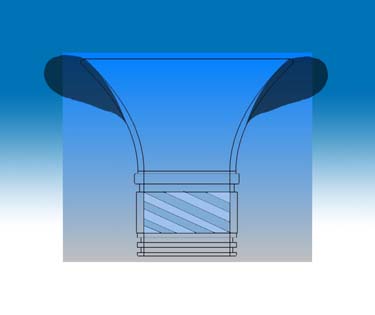

Here ya go  | ||

Jerseyguy |

Spiderman - I dunno. I'm assuming more air is better and for more air you need laminar flow. | ||

M1combat |

Maybe a rifling so to speak. I would imagine the the "polygonally" rifled system used in an H&K USP/SOCOM barrel would be best as there are no lands and grooves. I wonder if mounting thin pieces of lexan or something equivalent to the top of the airbox at a four to seven degree angle as the air comes over the lip of the stack to promote a vortex in the velocity stack would do anything? I would try it, but I don't have any place that will offer me free dyno runs... | ||

Spiderman |

Actually I wouldn't do it on the lip. I would do it further down. Right on the inner tube just before it reaches the throttle body. | ||

Jerseyguy |

This profile is an attempt at having the stack geometry such that its area is decreasing at a constant rate. The theory being that the air will see constant acceleration. It is the same height and OD of the stocker. For my fellow geeks, the equation is Radius=C*y^2+ri. It doesn't address the rolled inlet edge very well. Steve  | ||

Spiderman |

Now imagine putting a twist on that acceleration... | ||

Fullpower |

yeah sort of a flushing motion. i think ross perot used that concept in a speech back in '92 | ||

Glitch |

| ||

Stot |

Yeah its called swirl and could aid vehicles with 1 carb per cylinder mainly. Reason being that the swirl around 2 cylinders might be in contradiction to each other and adding a clockwise swirl would hinder a counterclockwise swirling cylinder. I would expect that back to back cylinders would swirl in opposite directions. Cya Stot | ||

Buellsnblondes |

Yikes....was hoping this solid stack would have improved things a weeeee bit. Nice job though, beautifully done, and nice install. Azfirebolt- tried to get up your way last Saturday but that damned parade had all the roads closed. Might be out at the Pavillions this Sat. night... keep in touch, perhaps a ride in the not so distant future! Bubba- did the airbox swap on my Buell Race kitted 9R, biggest difference for me was in the mid-range. It's good having people like you in the midwest with the interest and time to improve the product. With such nice weather here year round, I doubt I would have ever experimented with some of these changes..too busy riding! Regards, Ed | ||

Buckinfubba |

ed you call north carolina the midwest....damn I wish it was....but with all the mountains the corn wouldn't grow as well..... now dave is in the midwest...snow and Ice and cold...south ain't so bad | ||

Hootowl |

Turbulent air only helps with carburetors, as it helps keep the fuel suspended in the air. EFI intakes are dry. Smooth is best. Though I understand dimpling makes the air not "stick" so much to the walls. | ||

Spiderman |

>>>Turbulent air only helps with carburetors Yes cause helping to atomize that fuel even more would not help... Any way you can mix that air more with that fuel more eficently the better the burn FI or Carb. | ||

Wyckedflesh |

Turbulant air helps FI but you have to remember where it is the fuel mixes with the air. The turbulance needs to be after that point. | ||

Opto |

I don't get this. The closeness of the lid creates a restriction, yet the 12's airbox lid improved HP. Maybe someone can explain this. Jersey, wouldn't the closeness of the lid simulate the effects of a longer stack? Instead of being a tube though, it has the shape of a mushroom. | ||

Steveshakeshaft |

Forgive me if this is gibberish but........ seeing as there is a bit of brain storming going on here. Regarding the wave tuning of the inlet tract. The Buell engine will suffer to some degree from the unevenly spaced induction strokes? Is there enough room in there to make two seperate runners, front and back cylinder, with an injector squirting into each runner? You can then tune the inlet without the "crosstalk" between the cylinders? Just an idea...... Steve steve_s@ukbeg.com www.ukbeg.com | ||

Jerseyguy |

I really think we are after laminar flow here to stuff as much O2 as we can through the inlet tract. Opto - That's a thought.... I wish now we had dyno'ed without the airbox on - just for comparison sake. Steve's - Might work, but it's outside the scope of this project. We have a bit of a consensus here and elsewhere that a heavily rolled upper edge would help. The problem with this is that you can't assemble the stack to the throttle body without lifting the airbox base to get the screws in (If you never removed the stack you might not understand what I'm saying). So there is a limit on how much return you can put on the mouth of the stack. If you look at the model above you can also see that the stack sits too high into the filter. I guess this is a cosmetic thing as the "tank" cover would look bad if it was higher. I have an idea that I need to work out "on paper". I can make a two piece stack where the top half screws into the bottom half. That way I can make different shape uppers for testing and the bottom below the filter cover stays fixed. It also eliminates the assembly hassle. It ain't gonna be cheap..... $hit, I need a sponsor... LOL. Steve | ||

Hootowl |

"Yes cause helping to atomize that fuel even more would not help... Any way you can mix that air more with that fuel more eficently the better the burn FI or Carb. " "Turbulant air helps FI but you have to remember where it is the fuel mixes with the air. The turbulance needs to be after that point." Yes. The turbulence needs to be IN the head, as most injectors spray the fuel almost directly into the intake of the head. At that point though, turbulence in the head would only serve to detract from laminar flow I think. The separation of fuel from air traveling the distance from the injector to the valve is miniscule compared to the separation that occurs from venturi to valve in a carb'd motor. Jeff | ||

Hootowl |

steveshakeshaft. I have often thought about that two runner idea. Makes perfect sense. To me anyway. Makes me wonder why no one (that I know of) has tried it yet. | ||

Daves |

Oh, it's nice in Iowa today, nice and cold! 6 more inches of snow coming. Yes, Bubba, the south ain't bad. But it gives me time to carb the XB! Ride to the edge! I've lost 12 lbs now! Dave Iowa HD/Buell (Buell Cycle Center) | ||

Cyclonecharlie |

Hootowl, Doesn't Aprilla use two throttle bodies (like 50mm)? Don't know if their lenghts are identical..Later Charlie | ||

Buckinfubba |

charlie where ya been hidin out ya big lug | ||

Buellsnblondes |

Sorry Bubba, got yours and Daves geographics switched.. After 10 years in Omaha I know the difference! Anyhows... do you know where I can get a quality single seat cowl for my 9R. Thanks, Ed  | ||

Buckinfubba |

do you mean the stock cowl. if so I could get that for ya buckinfubba@hotmail.com | ||

Hootowl |

Charlie, I don't know. I was thinking about HD and Buell specifically. Maybe there's not enough room in the V for two intake runners? Maybe the heads could be redesigned so that the intake mounting bosses were angled away from each other? I think it's possible. It would make tuning them easier, as you're only dealing with the pulses from one cylinder. That would mean two throttle bodies too. Might be easier to do on an XB due to the downdraft configuration. Jeff | ||

Blake |

Jerseyguy, You might be surprised to learn about the effects of a turbulent versus laminar boundary layer, not wrt the airflow in general, just the boundary layer, big difference. Turbulent boundary layer = very thin boundary layer. Laminar boundary layer = progressively thicker boundary layer until fully developed. Boundary layer = lost area supporting free flow. Boundary layer bad.  Big thick boundary layer causes much drag and loss of lift on large aircraft. Some wings have little tiny turbulence generators to make boundary layer turbulent instead of laminar. Some even include little holes attached to vacuum to suck away big thick laminar boundary layer. Big thick boundary layer causes much drag and loss of lift on large aircraft. Some wings have little tiny turbulence generators to make boundary layer turbulent instead of laminar. Some even include little holes attached to vacuum to suck away big thick laminar boundary layer. I think whoever mentioned the effect of the XB12 airbox being akin to a longer intake tract may be onto something, that and by virtue of its shape it provides a significantly lower resistance to flow into the orifice. Yes, sometimes adding material within the pathway of an enclosed compressible fluid duct can REDUCE resistance to flow. Bottom line though is that I just don't see any significant gains to be made through modification of the velocity stack. It is fun to talk about though. | ||

Jerseyguy |

Blake - I hear you. I did actually dig out my fluid mechanics college textbook from the 60s and read up on compressible fluid flow. To think I used to know what all that $hite meant...... LOL. Everything you said is basically true. There are alot of variables here though, that resist calculation and require empirical data. I think my polishing of the stack to a mirror finish may have been a mistake (It sure is pretty though). I'm going to bead blast the next one on the inside. Have you seen that recent car commercial that rotates the car upside down in a wind tunnel? It touts the dimpled undercarriage as a drag reducing technique. Makes you think. Steve | ||

Spiderman |

Wow a greezy wrench was correct a duurrrrr  | ||

Jerseyguy |

LOL Spidy - You'll be glad to know I just glass beaded the hell out of it. Gotta be good for a couple of HP. Steve |