| Author | Message | ||

Rsm688 |

Well I got my M2 stripped down to just the frame/suspension/motor/primary/swingarm today. Got all the wiring and brakes and body work and all off. Anyways, tomorrow I am gonna finish the job up and have a few questions. What is the best way to remove the rear isolator bolts? And does anyone know what size bit is needed? Im gonna have to pick one up and would be easier knowing what size I need. Should I use an impact wrench or breaker bar? Also, what is the best way to lower the motor down? Ive got a small floor jack and still have the rear wheel attached. I was thinking maybe just a small piece of wood under the block and then use that jack to lower it. Any suggestions or any other tips on pulling the motor/primary/swingarm out would be greatly appreciated. Thanks, Spencer | ||

Kc_zombie |

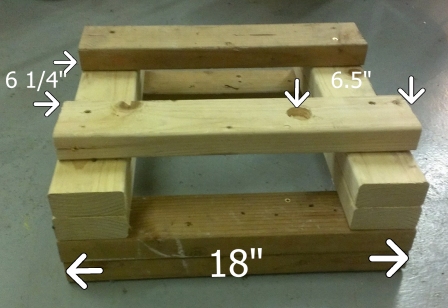

Support the motor from underneath and strap it down then lift the frame off. The frame is allot lighter than the motor. you can leave the swingarm and block on the motor, just undo the isolator bolts. When you think about it, with most bikes the motor goes in the frame, but with a Buell the frame goes on the motor. These pics may help...   | ||

Kc_zombie |

Here is another shot with the frame "on the motor".  | ||

Rsm688 |

Thanks again for all the help KC, the plans for the wood block look perfect I need something to leave it sitting on while I do some work. What is the 6.5" to the hole for? I'm guessing oil drain bolt? | ||

Kc_zombie |

Primary chain tensioner bolt/assembly (I don't remember the diameter of the hole, but I am sure you can figure it out). It will fit in the hole and the motor will sit level. No problem, hope it helps. Good luck and keep us updated, allays like to see a build progress! | ||

Jim2 |

For the rear iso bolts you can buy a threaded-rod "Coupling Nut" from the hardware store. Get a 5/16"-18 X 7/8" or longer. The nut will fit inside of a 1/2" socket and can then be used like a giant allen wrench. | ||

Rsm688 |

Jim, I'm kinda confused about the coupling nut and what you would use it for. I know I would need a bit to for the boots to remove them and I get that it would work in a 1/2" socket (worked at fastenal for years in college so know y hardware). I just dont get what your saying to use for the other end of the nut. Oh wait, as I'm typing this I had an idea. Is the isolator bolt 1/2" Allen? And you just use It like the bit and use the socket to hook to the breaker bar? Thanks, Spencer | ||

Rsm688 |

And KC, got a build thread started just a few threads below this one "Buell Cafe Fighter Build", will keep it updated with pics and progress of the build. Thanks, Spencer | ||

Natexlh1000 |

The coupling nut idea might not be so good. Proper allen wrenches are heat treated and won't round off the corners as easily. I used a huge old allen wrench and cut a segment off for the same idea. LOTS of torque to loosen them up. Best to break them loose while bike is in one piece. | ||

Jim2 |

The coupling nut is just a cheap alternative to the proper allen tool. I had no problem when I used it. I learned about it here from others who have also used it. If you have the correct tool than by all means use it, I am just providing a cheap alternative that I found convenient for me. I used new iso bolts with my new isolators but it turns out that I really didn't need to. The old bolts were on pretty good and I did use a 16" or 18" 1/2" breaker bar to loosen them. | ||

Bluzm2 |

Jim, I've use the coupling nut trick many times with no issues. |