| Author | Message | ||

S21125r |

Saw this in another section of the board. A little old but... http://www.badweatherbikers.com/buell/messages/253 912/608165.html?1293892402 ..it lead me to think of this crazy idea for an internally finned brake rotor. Conceptually the best way to describe it is to take to 2 standard thickness rotors. On one you machine shallow channels into one rotor face so that there are - arbitrarily - 36 radial bosses left over (every 10 deg). On the other rotor you do the same thing except you index the channels 5 degrees. Stack the 2 so that bosses of one rotor mesh with channels of the other and visa versa. Resistance weld them together and then surface grind the whole stack back down to stock thickness. Probably get creative and curve the channels so that they scoop air like a centrifugal air pump to promote air flow through the channels. Probably be pricey considering the amount of machining but you might be able to cast the two halves up to minimize some machining. Also not entirely sure if this is sound thinking from a thermodynamics perspective... My guess is that at a minimum the two halves would have to be resistance welded to ensure even and consistent heat transfer, but I would be worried about the 2 halves "delaminating". Not that I ride hard enough to need a finned rotor, but I come up with these crazy ideas every so often and need an outlet for them.  | ||

Stirz007 |

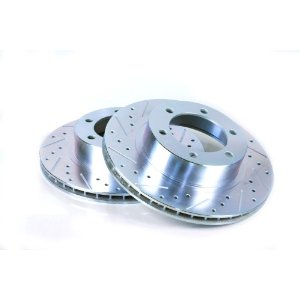

Ya mean something like this?  | ||

S21125r |

Exactly - just thinner for motorcycle applications. Probably too thin to cast directly, hence the need for 2 pcs, machining then welding. | ||

Gunut75 |

We had this idea when developing a disc brake for cart racing. The problem we ran into was that the welding created hard spots in the disc. It brought a quick end to the project. A new manufacturing method was needed. | ||

Boogiman1981 |

cast thick enough to drill then cut down to desired thickness | ||

Sprintst |

the question is: is this a solution looking for a problem? Car wheels impede airflow to the rotors - hence some high performance cars, like the 1985 Corvette, features wheels designed to pull air into the rotor area. Club racers run ducts. Motorcycles don't have that impediment. Additionally, the ZTL rotor has so much swept area, I wouldn't think heat would hardly ever be an issue | ||

Jdugger |

> I wouldn't think heat would hardly ever be an issue Bwa ha ha ha ha ha ha ha ha Heat is a HUGE problem with the ZTL2 system. | ||

Sprintst |

wonder if the rim impairs airflow then so much area...... | ||

Boogiman1981 |

i was gonna say you might wanna go look at pics out there of rotors that have been used at track days and on race day talk about HEAT it's amazing those things can stop at all after looking at some of them. there's a reason that they use brake fluid circulation systems with large reservoirs and even coolers plumbed in | ||

Sprintst |

race cars have fluid cooled rotors try that! | ||

Aseecobra |

Erik Buell Racing shows a finned front rotor. Finned rotors for karts have been around for a long time. Fluid cooled rotors? Fill me in on that. There are fluid cooled calipers with internal cooling passages. | ||

Usanigel |

You're a little late! Honda CBX 1000 in 1982 had them. I'm sure a few others too. | ||

Sprintst |

Might have been a Pop Sci article on it a few years back, as I remember. not sure if they ever made them, but they ran coolant through the hub up into and out of the rotor | ||

Drawkward |

| ||

Anonymous |

I know, I know, heat is such a huge problem with the ZTL system. It's a good thing no one told Geoff, Danny, Pat, Harald, etc... BTW, Honda and others already made brake discs just like the OP suggested. Has more problems than it solved, but obviously not a bad idea since they tried. | ||

Jersey_thunder |

ZTL2 HAS HUGE HEAT PROBLEMS?...  , DO TELL... , DO TELL... | ||

Jdugger |

Who is this anonymous person? With the ZTL2 design, heat is definitely a problem. It's why racers almost universally need RBF600 or other high performance fluid. It's why the rotors turn dark blue, purple and black. It's why rotors are a major wear part on the 1125r in racing applications and require servicing more frequently than dual disc designs. One of the Pegasus bikes actually had a fluid circulation circuit in the caliper to help with the heat. And, the new brake hardware, along with the 5mm finned rotors is specifically intended to cool the rotor by exposing more edges and surface area to the air as well as increase contact with the wheel to help dissipate heat. I'm a huge fan of the ZTL2 system, but the facts are heat is one trade off in the design of that braking system. Better MCs, fluid, pads, mounting hardware, vented front fenders, and so on for this system all exist for a reason guys. | ||

Dktechguy112 |

Jdugger, It is usually Erik Buell Racing that posts up as anonymous around here. If you do not race the bike, then the brake system lasts a long time and works great. If you race, you should be able to frequently service the brake system and change out the rotor and pads. It may go through pads and rotors quickly, but anonymous's point is that on the race track it doesn't overheat to the point that it fades. Watching geoff this season you could tell that he was late braking and flying into the corners, you can't do that if you don't really trust your brakes. | ||

Ducxl |

Not finned.....CERAMIC | ||

Jdugger |

> It is usually Erik Buell Racing that posts up as anonymous around here. In this case, I don't think it is. And, here's why: I have had heat problems with braking fade and heat, and it's specifically talking with the Erik Buell Racing guys that led me to the new hardware, 5mm finned rotor, etc. Those guys know the stock system isn't race ready. I'm not saying you can't race the ZTL system. (I do, in fact) I'm saying heat is a problem with it and many steps have been taken to remedy those issues. To say heat isn't a problem just because some racers are successful on it isn't the whole story. The original post was someone who couldn't imagine the ZTL system having a heat problem. Well, it does. Yes, it can be remedied, but if you take the stock system out to the track and you are good on the brakes, you are GOING to fade it. Also, the Pegasus Superbikes and I presume the 1125RR that Geoff rides are using the ZTL2.5 caliper, not a stock caliper. For this, the stock caliper is milled to allow greater airflow around the caliper, the outer dust deals removed, and the pistons upgraded to higher quality material which is exposed to more cooling air. So, let's see here. The ZTL2 system works perfect in race situations in top racing leagues when you: * Replace the caliper with one modified for better cooling air flow * Replace the rotor with one designed for better cooling * Replace the mounting hardware with new parts designed to dissipate more heat into the wheel * Replace the brake fluid to a high performance, high boiling point fluid ... and y'all wanna tell me heat isn't a problem? | ||

Blake |

Which competitive Superbike team runs an OEM front brake system? Answer: None. Why is that?  Heat is an issue for every OEM superbike braking system on the grid. On some tracks, the leading superbike racers routinely adjust their front brake lever travel in order to compensate for brake fade during a race. OEM brakes on repli-racer superbikes have been continuously and repeatedly re-engineered over the years in order to address exactly the same type of issues that Erik Buell Racing is also having to address on their racing machines. Announcing that front brake rotors get hot and suffer accelerated wear on a superbike in racing as if the same is not also true for all other competitive superbikes in racing is unfortunate and certainly not an honest portrayal of what goes on at the track. Braking from near 160+ mph is going to heat every single front brake rotor on the track to extreme temperatures. There is no free lunch. Here's a news flash: The Erik Buell Racing machines also require tire changes every race! OH MY! Tire wear is a problem for racing Erik Buell Racing motorcycles! This is outrageous! Erik Buell Racing needs to come clean on this problem and find a way to make tires last longer! To deny that tire wear is a problem is outrageous!  Everyone wants to be an expert critic. | ||

Blake |

To clarify, I totally dig discussion about ideas to improve stuff and potential new technology. I just don't appreciate making out like Buells are the only bikes having to deal with brake heat issues on the track, or the ludicrous notion that only Buell rotors get extremely hot when exposed to racing conditions, or that Buell racing machines are the only bikes to benefit from aftermarket brake parts. Red hot is red hot, whether two conventional or one ZTL type rotor. (Message edited by blake on January 11, 2011) | ||

Jdugger |

Blake, I didn't make out that Buell is the only one. I said it has heat issues. Even ME, a NOVICE racer, has had to do some decent upgrading on the ZTL system to get it to perform well and not suffer heat related issues. On our Honda race bike we were able to get by with just a fluid upgrade. Oddly enough, because of a crash on the Honda we are actually using the OEM Buell MC for the front brake there -- I had an extra lying around after my RCS19 upgrade on the Buell.  The Dual Disc systems simply have more disc and more mass to take the heat. Yes, they still have problems, but the ZTL system is somewhat more prone to heat related issues by the nature of it's design. As you said, there's no free lunch. Remember, you are talking to someone who loves the ZTL brake, who races a Buell at the club level (like you did at one time) and who probably has more track miles in the seat of an 1125r than just about anybody. Buell made some legitimate engineering trade offs with the design of the ZTL2 and more heat relative to a dual disc system is one of them. (Message edited by jdugger on January 11, 2011) | ||

Court |

>>>but if you take the stock system out to the track and you are good on the brakes, you are GOING to fade it. Tough to argue with that . . .it happens to Honda CBR Yamaha R1 Buell 1125 Arillia Ducati Rousch Mustangs Good point. | ||

Jules |

So just to summarise: If you're going to competitively race the 1125R you need to upgrade the brakes.. but if you're just using it as it was originally sold to be used (riding on the street) all is well in the world.. The same appliues to pretty much every bike out there I believe.. Umm, did anybody learn anything new today? | ||

Jdugger |

Jules, I would say the need to upgrade the Buell brakes came sooner. Our endurance race bike (a dual-disc, UJM) is essentially bone stock. | ||

Skntpig |

Turns out CTS-V Cadillacs have this problem too. I just put new rotors, street/track pads, Motul RBF600 and Stainless Steel brake lines on my ummm car. Now it squeaks when I stop easy. Wooah is cheaper than Go | ||

Blake |

Jim, >>> The Dual Disc systems simply have more disc and more mass to take the heat. You sure about that? I think the advantage may be more total pad area and especially having the calipers' openings facing into the oncoming (cooling) airflow. The ZTL caliper with its open side facing rearwards impedes cooling airflow from circulation between pads and rotor. >>> Yes, they still have problems, but the ZTL system is somewhat more prone to heat related issues by the nature of it's design. As you said, there's no free lunch. Well said. I agree. I appreciate your now thoughtful tone. Your orignal comment... Bwa ha ha ha ha ha ha ha ha came across as VERY inflammatory and antagonistic. (Message edited by blake on January 11, 2011) | ||

Jules |

Our endurance race bike (a dual-disc, UJM) is essentially bone stock. OK I did learn something new today - thanks  I love this place  | ||

Blake |

Devin (Dktechguy112), >>> It is usually Erik Buell Racing that posts up as anonymous around here. Pretending to know who may or may not be posting anonymously here indicates a willingness to proclaim that which you in fact do not know. That's a bad habit to adopt. |