| Author |

Message |

Puzzled

| | Posted on Wednesday, August 11, 2010 - 07:41 am: |

|

No more gaps/space differences.

|

Puzzled

| | Posted on Wednesday, August 11, 2010 - 07:42 am: |

|

The original center piece of the compensating sprocket.

Cut the flange off.

|

Puzzled

| | Posted on Wednesday, August 11, 2010 - 07:42 am: |

|

Turned down to maintain the original thickness of the compensating sprocket as well as maintaining stock bolt length.

|

Puzzled

| | Posted on Wednesday, August 11, 2010 - 07:44 am: |

|

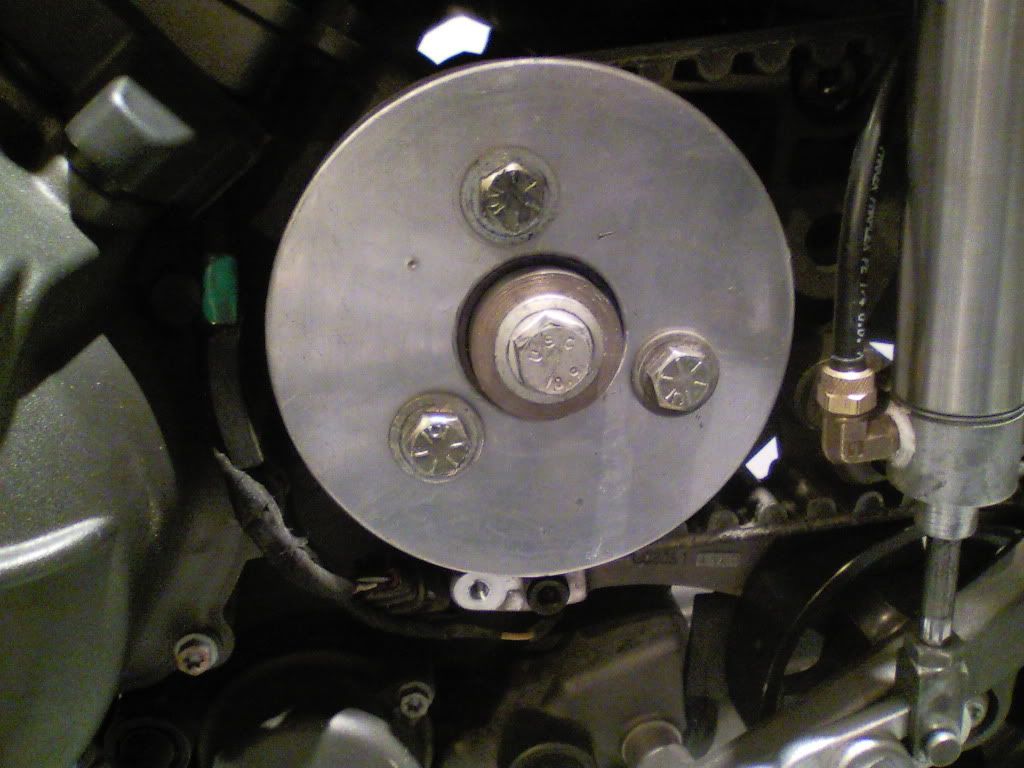

The aluminum piece on top is the belt retaining ring. It will get drilled along with the flange which also gets tapped and drilled for 7/16" dowl pins. So I'll have 3 bolts holding the assembly together as well as 3 dowl pins to drive the pulley.

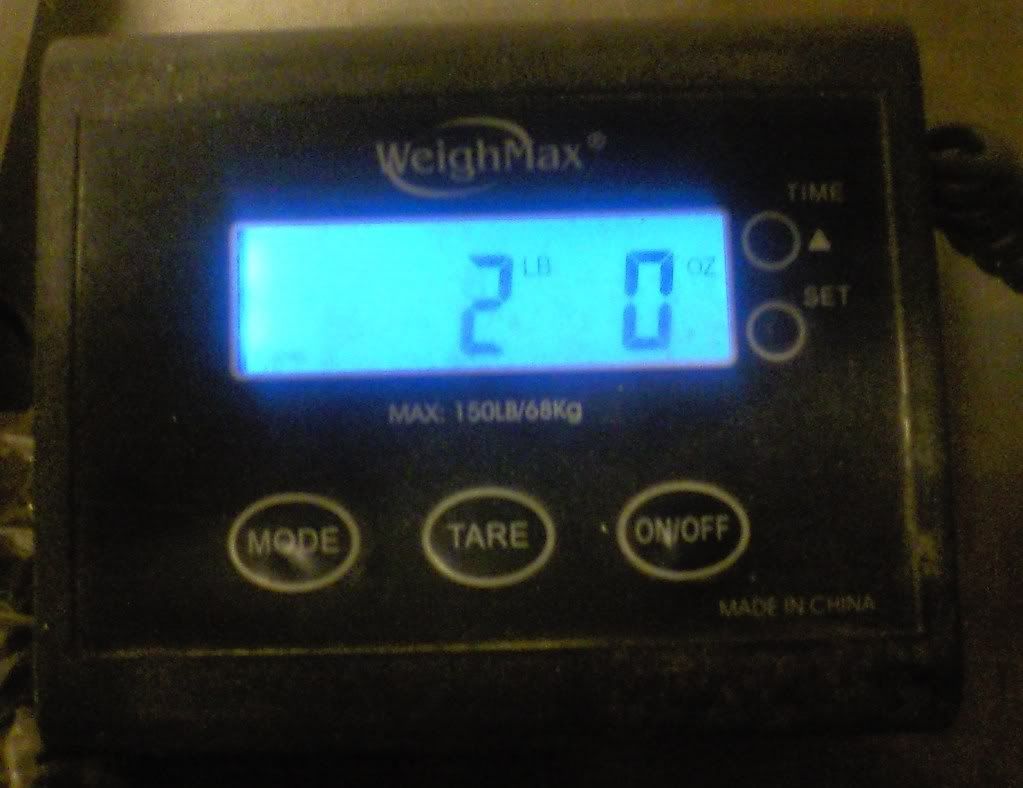

The new assembly with the 27 tooth sprocket weighed in at 2 pounds 6 ounces. That is 2 pounds 8 ounces lighter than stock. What affect do you think that will have on the motor spooling up? Rotating mass!

|

Puzzled

| | Posted on Wednesday, August 11, 2010 - 07:44 am: |

|

The 25 tooth magnesium pulley weighed in at 2 pounds even. 2 pounds 14 ounces lighter than stock!

|

Puzzled

| | Posted on Wednesday, August 11, 2010 - 07:47 am: |

|

I machined all three pulleys so I can maintain stock gearing as well as dropping two teeth in the front. I may consider machining one more pulley, a 28 tooth. This may help with some top end for the MPH runs.

27/70 = 2.59 to 1 Stock R gearing

26/70 = 2.69 to 1 (4% change) 1 down on trans sprocket

25/70 = 2.8 to 1 (8.3% change) 2 down on trans sprocket

After drilling and pinning the the hub next up is seeing how the belt and tensioner will take these changes. If there isn't enough movement on the tensioner to take up the two tooth change I may make a slightly larger idler pulley.

I ordered my hardened pins and grade 8 hardware last night. Just to be sure I also ordered a tap and drill bit for hardened material. I should have the material in a few days. |

Boogiman1981

| | Posted on Wednesday, August 11, 2010 - 10:59 am: |

|

so it looks like the the need for chains just went away. if you were to make those for sale any idea on what you'd charge? |

Jdugger

| | Posted on Wednesday, August 11, 2010 - 12:03 pm: |

|

I'd actually be interested in lightweight rear pulleys. On my 16.5 forged mg wheels, the pulley ways more than the wheel! |

Motorhead102482

| | Posted on Wednesday, August 11, 2010 - 12:07 pm: |

|

A billet anodized drive pulley would be awesome. The problem is that we don't know what the effect is of driving without the compensator part of the pulley in there. Will there be any harm to the driveline without that cusion? |

Chevycummins

| | Posted on Wednesday, August 11, 2010 - 12:15 pm: |

|

So what was the reason for the engineers to design the compensating sprocket in the first place. Is it to dampen engine pulses to increase the life of the belt, or some other reason? Love the machine work on the parts Puzzled, I can't wait till I get my metal lathe. |

Puzzled

| | Posted on Wednesday, August 11, 2010 - 12:44 pm: |

|

A billet anodized drive pulley would be awesome. The problem is that we don't know what the effect is of driving without the compensator part of the pulley in there. Will there be any harm to the driveline without that cusion?

I would say there is no adverse affect by removing the compensating sprocket. My reason behind this is that the chain drive kits eliminate it.

The compensating pulley or similar cush drive I believe is put in place to soften the initial hit of the clutch engagement. without it bikes can tend to be a bit more "jerkey" upon clutch release. I can only base this on my first hand knowledge of the several bikes I own. For me this is not an issue.

(Message edited by puzzled on August 11, 2010) |

Puzzled

| | Posted on Wednesday, August 11, 2010 - 12:51 pm: |

|

So what was the reason for the engineers to design the compensating sprocket in the first place. Is it to dampen engine pulses to increase the life of the belt, or some other reason? Love the machine work on the parts Puzzled, I can't wait till I get my metal lathe.

I believe you are thinking along the correct lines. My one bike does not have "dappening" anything. I"m able to hole shot that bike without breaking or skipping the belt. The Buell offers the tensioner which makes it all that much better as it will attempt to eliminate belt slap.

Owning a lathe is nice. It certainly opens a lot of possibilities. The mill is equally important to have.  } } |

Puzzled

| | Posted on Wednesday, August 11, 2010 - 12:54 pm: |

|

I'd actually be interested in lightweight rear pulleys. On my 16.5 forged mg wheels, the pulley ways more than the wheel!

I found 72 tooth rear pulley blanks made of aluminum}. Combine that with the front 25 tooth and that should make it a 2.88 to 1 ratio. That would be a several gear wheelie bike! |

Puzzled

| | Posted on Wednesday, August 11, 2010 - 12:58 pm: |

|

so it looks like the the need for chains just went away. if you were to make those for sale any idea on what you'd charge?

A chain is pretty dam strong and very common. The belt even with pulley choices won't run the chain out of town. The 2K conversion is a bit pricey. The odd color arm is a point I can't get past. Offer me a blue arm and maybe..... (no interest in changing the color on my end, it should come that way!)

As for reproducing this? Let me test it first. I don't see }a demand for such a thing for street guys. Various forms of racing?, yes. |

V74

| | Posted on Wednesday, August 11, 2010 - 02:40 pm: |

|

i cannot believe that the 1125 front pulley weighs so much,i recently got a 27 tooth front pulley for my 99 M2(not installed it yet)to swap from the 29 thats on it,it weighed 1261g,i have drilled/ground off 170g(now making it 1091g)i thought i was doing well but you have done better but i would have expected the more modern 1125 would have had a lighter pulley than mine ??? |

Boogiman1981

| | Posted on Wednesday, August 11, 2010 - 05:59 pm: |

|

by all means test away man. i don't have that kind of machining ability or tools. the no chain comment was more for those of us that are casual and or like the stock look but would like to play with gear ratios a bit |

Puzzled

| | Posted on Wednesday, August 11, 2010 - 06:22 pm: |

|

^^^^ I understand. I like the belt also so I hope this works as planned. I should get to bolt it on in the next day or so just for a test fit. |

Skntpig

| | Posted on Thursday, August 12, 2010 - 12:41 pm: |

|

Do you have the chain swingarm to adjust the length?

How are you going to "compensate" for the diameter difference? |

Puzzled

| | Posted on Thursday, August 12, 2010 - 01:30 pm: |

|

Do you have the chain swingarm to adjust the length?

How are you going to "compensate" for the diameter difference?

I'm working on that as I type this. My intentions are to replace the idler pulley with a tensioner pulley. I have some preliminary belt tension readings from the stock set up and now I'm trying to convert them over to what the tensioner industry uses.

As a quick test I bolted a manual XB chain adjuster to the bike (with the sprocket removed). That will definitely take the slack up. Now it is a matter of getting the tension correct with either an elastomer or spring type self adjuster. For my application a manual adjuster is just fine as my suspension is strutted for drag racing hence no swing arm travel. However I would like something that will adjust on its own for the various pulley sizes while maintaining sufficient tension}. |

Dannybuell

| | Posted on Friday, August 13, 2010 - 11:35 am: |

|

Nice work! I am very excited to see things evolve in this direction. |

Puzzled

| | Posted on Friday, August 13, 2010 - 04:06 pm: |

|

I have the 27 tooth light weight version on the bike now (2 1/2 pounds lighter). Provided UPS gets here at a reasonable time I'll get to the track tonight and test the pulley. |

Puzzled

| | Posted on Saturday, August 14, 2010 - 09:57 am: |

|

Here is the 27 tooth pulley pinned and bolted with the belt retainer in place.

|

Puzzled

| | Posted on Saturday, August 14, 2010 - 10:18 am: |

|

My intentions are to replace the idler pulley with a tensioner pulley. I have some preliminary belt tension readings from the stock set up and now I'm trying to convert them over to what the tensioner industry uses.

As a quick test I bolted a manual XB chain adjuster to the bike (with the sprocket removed). That will definitely take the slack up. Now it is a matter of getting the tension correct with either an elastomer or spring type self adjuster. For my application a manual adjuster is just fine as my suspension is strutted for drag racing hence no swing arm travel. However I would like something that will adjust on its own for the various pulley sizes while maintaining sufficient tension.}

|

Puzzled

| | Posted on Saturday, August 28, 2010 - 12:06 am: |

|

I finished my tensioner project this week. The first one wasn't quite strong enough so I used the next one up which seems to be just fine. With 11 runs on the bike tonight everything is working as it is suppose to.

|