| Author | Message | ||

Brinkba |

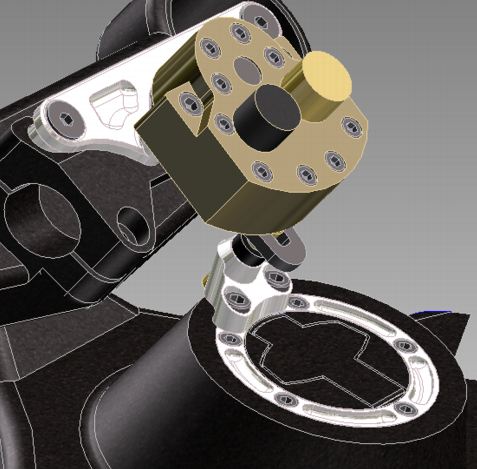

After finding out there is no steering damper for the 1125CR on the market. I made my own bracket for fitting the scotts steering damper on my CR. I think the scotts damper is probably the best steering damper on the market, but have not any experience with the GPR. I made a bracket which mounts on the 2 front handlebar brackets bolts (replaced them for M8x50 countersunk) which holds the damper unit. Next to this I made a bracket which mounts on the 2 front torx holding the gas-cap base (replaced them for M5x25). This brackets hold the pin. I altered the gas-cap to make room for the bracket. Because I want it to try fit first I made the pieces mainly by lasercutting them out of 5mm stainless steel. Originally I wanted them to be milled from Fortal alumium and have a ring shaped bracket so it could be mounted using all 5 M5 bolts and optionally combine it with a excisting or new design gas-cap. However the milling was quite expensive for just 1 set. The bike feels more at easy in the higher speed corners and I'am more convident on it knowing the damper is there to do its job. I'am happy with the end result. Just finished painting the parts black which even looks better. You can mount the scotts damper the other way around but it will block partly your sight on the odometer.  | ||

Paulp1125cr |

Nice job, I've been trying to figure out a way to mount one on my cr and that seems like that works. Any chance u could throw up so more detailed pics? I'm a machinist and have access to a variety of machines including a 5 axis mill. I luv making stuff for the cr. | ||

Ezblast |

I'd really like to buy such an adapter kit - either of you start to sell one - let me know please. EZ | ||

Puzzled |

Very nice job. Props for making what did not exist. | ||

Andros |

I want one! | ||

Captain_america |

Me too!!!! | ||

Hack_job |

where do I send the money? | ||

Westmoorenerd |

I'm down to buy one! | ||

Smoke4ndmears |

you are now the patron sait of CR owners everwhere. | ||

Datsaxman |

Very nice...trying to ride slowly enough to keep my license for a while. Not easy...but we do get the occasional head shake. Very nice indeed. | ||

Attweco |

That is sweet!  | ||

Skntpig |

Does want. Must have. Do you have pics of your master cylinders? | ||

Cherry_bomb |

very cool, more pics please...i want that one! | ||

Brinkba |

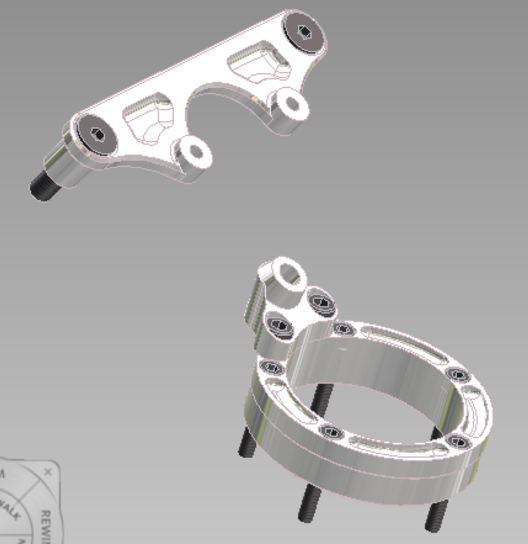

Here are some more pictures.  brake master is a braking 19mm, clutch a brembo, reservoirs are rizoma's  Next 2 pictures are 3d images of the brackets as they could be made of alumium. Set based on production of 10 units will be around 200 euro per unit. A unit including a racing fuel-cap will be around 275,- The ring shaped adapter could be used for other purposes such as mounting a camera or tank bag. Extra tapped holes are easily made. If anybody thinks he will be able to make the parts at a better price I am willing to trade the design.   | ||

Louisiana_xrider |

Somebody with the machines and skills please make and sell these. I am tired of the drastic headshake that mine produces at high speeds. | ||

Aseecobra |

Brinkba, Who makes the handlebar? | ||

Captain_america |

Depending on material required, I could do it. I dunno if it would be that pretty but I could give it a shot I'm just a self taught shade tree CNC operator/programmer | ||

Paulp1125cr |

I could make it axactly as u see it but I would have to make quite a few for that price, just the aluminum alone would be quite expensive. But if there were enough people serious about it I would look into it. I could even anadize it a variety of colours which would really set it off! With the designers permission. I'm not looking to steal anyones good ideas and this one is a great idea. | ||

Duphuckincati |

So the question is how much steadier is the ride at speeds over 125? My high bar CR gets pretty active around 130 in the handlebar department. | ||

Cherry_bomb |

why is nobody doing something like this, it worked on the xb's and it will work on the cr/r? http://www.buellxb.com/buell_images/1622_200810091 12614_L.jpg | ||

Westmoorenerd |

Man I was down until I realized it was $700 with the gas cap =/. The bracket with the cap alone costs more than the damper. | ||

Al_lighton |

I had a similar layout for the XB's a few years ago, had some communications with Scott's about producing it. But I didn't run with it because of product liability concerns about what would happen in a wreck. I know that Buell has some design considerations about how the front end separates from the bike under crash load so as not to cause fuel loss, but don't know enough about that to incorporate it into the design. If anyone runs with this, just be sure to have some type of mechanical "fuse" in the design so that under no condition can the integrity of the fuel cap/seal be compromised. I'm a big fan of rotary dampers. They're very adjustable and easily done from the cockpit, and they stay out of the way in a wreck. But they sure are damned hard to implement on the Buell fuel-in-frames. Al | ||

Fastfxr |

im very keen to buy this kit | ||

Avc8130 |

Al, I think the mechanical fuse would simply be how the damper connects to the frame mounted portion. It is simply a post run up into a slot. No way that will ever be stronger than the frame. ac | ||

Al_lighton |

Anthony, I tend to agree. The problem I had is that it opened up the litigation avenue on a pretty serious issue. If a wreck occurred, and there was a fire related to gas cap seal, it'd be a tough fight. With the stock gas cap, nothing is proud, it is very difficult to compromise that seal. Once things aren't flush, there are potential crash load paths. It's a stretch, to be sure. In the case of the XBs, there were other damper options, so it made the point a bit more moot. In the case of the CR, it becomes a bit more compelling to assess the risk and design around it, because there are no other options at this time. BTW, nice implementation, Bas! The approach that I took duplicated the cap/frame interface and just raised it so that I could access the frame hard points that the locking ring attached to. I didn't even consider modding the actual cap, again, due to potential liability issues. But your mods to the cap look clean. Al | ||

Jbarron |

Has anybody looked at the mount used by the XB12 for the GPR stabilizer. It tied into the air cover screw and hand some arm that curved around to the pivot pin. The bar clamps are different on the CR so that part of it will not work, but with this bar mount and the GPR arm it might avoid any legal issues. | ||

Blur |

If anyone decides to make this kit using the Scotts damper I'll buy a kit. I've been waiting too long for something like this to come out. | ||

Ezblast |

Dito! +1 | ||

Rherlaar |

Hi Bas Best design I've seen thus far and if indeed someone ever decides to build this one - I'm willing to shell out the estimated cash as well. IIRC you mentioned that we'd need to be 10 to make economies of scale work for this project ...I suspect we're 10 already or did some get cold feet  I live in Belgium with little remaining access to CNC shops for one-offs (I know more of these still remain the Netherlands and Germany) but I could ask around . When i look at your 3D schema's though I can tell it's closely related to your profession so your assessment on pricing is very likely accurate. Keep me posted please. Kind regards Rik | ||

Elvisnixon |

I'll buy one! tom |