| Author | Message | ||

Dannybuell |

Thurstonbuell - "3) Would a rubber flap behind the screen mesh be effective ? dropping down and opening when more air is needed and acting like a check valve and closing when the ram air takes effect allowing positive pressure to build ? " That is a very interesting idea. How would you do it? :-) | ||

Rt_performance |

the ecm afv is not locked but it will never change in the cluster. if you unplug the 02's it will lock it to the base map . | ||

D_adams |

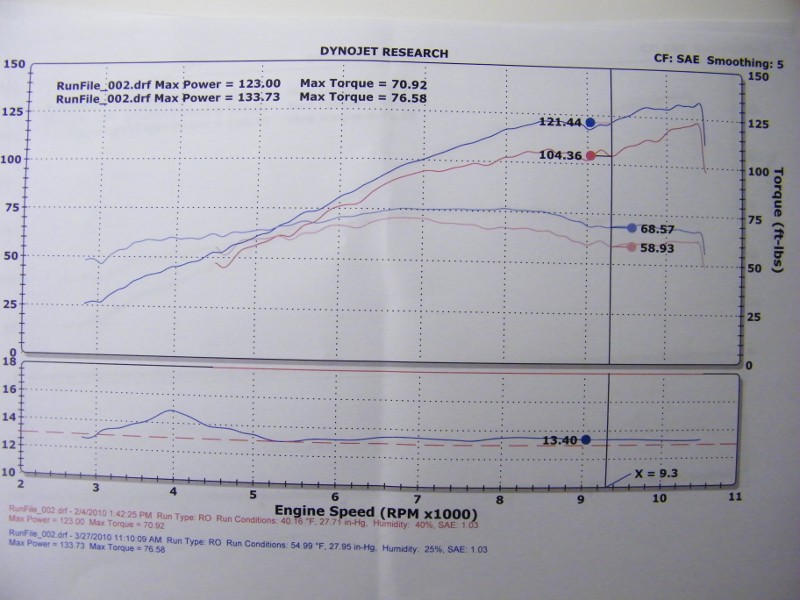

I'm going to argue this point. Below is a dyno chart, same bike, same intake, no tuning but with an aftermarket exhaust. Obviously the world + dog is waiting on the exhaust shootout, but this is the results from earlier this year, and it shows a HUGE gain over the stock pipe. Even if you only count peak HP, it's still almost a 10% gain. If you look at the largest gain, it's either 18 or 19 hp over stock. The dyno runs were done at Gateway HD in St. Louis MO. There are several systems out there that are capable of making similar power if not more, such as the Drummer, Barker's and others. Yes, it's apparently running lean there, but not excessively so. The systems I build aren't the only ones out there that make gains of this nature, and they do it without any tuning. Do they need it? Probably. Will the bike blow up from it, I seriously doubt it. Buell wouldn't have released the bike if that's what were to happen. Think of the cost of all the warranty engine repairs. It's simply not worth it to intentionally lean it out to cause damage from a manufacturer's standpoint.  (Message edited by d_adams on June 15, 2010) | ||

Easyrider |

Poor running bikes will break down earlier then, Normal-rich running bikes. | ||

Highscore |

Sorry, D_Adams, but as long this is the variation for performance on the dyno:  for the same bike, same (stock) exhaust, same day, same dyno due of "hot air effects" by the radiator fans, I cannot believe in such HP-wonders by a muffler swap. BTW: peak torque around 6800 with the stock exhaust, but a dip at 9000, sounds strange. This figure simply does not fit to headers length and cam timing. | ||

Thurstonbuell |

Danny, I havent a clue , lol What I was thinking is a thin flexible rubber placed right behind Bob Thompson mesh screen . The rubber material would be pulled down via the negative pressure . When you get up to speed and the air box cover becomes a positive pressure the flap would be forced back up against the screen material , allowing the ram air effect to take over..... I dont know if that would be worth trying , but I thought it sounded interesting ....IMO Ken | ||

Type911 |

Is there a cliffs notes that can sum up this thread. Looks like there are some free HP/TQ to be had. Hard to sift through all the info for us laymen. Thanks | ||

Steve_a |

Just one warning, which I see iterated above: YOU HAVE TO BE VERY, VERY FASTIDIOUS ABOUT CONTROLLING ALL VARIABLES TO GET COMPARABLE POWER MEASUREMENTS ON A 1125R! Some of that is true on all motorcycles, but it's particularly the case of the 1125R because of the cooling system/intake system interactions at low air speeds, things that have no effect whatsoever on 70 mph+ real world riding. The radiator fans dump hot air right at the intake pickup, and in a static dyno test, this kills power readings. In the real world, there's enough air flow that this doesn't happen at highway speeds and above, as can be seen by the dropping temperature with speed on the intake air temperature pick-up. We use to run blowers to ensure plenty of cool air reaching the inlet, and we ALWAYS ran power sweeps through various engine temperatures, and in comparable manner one test to the next. Bottom line: the 1125R on a chassis dyno makes a tuner's life a little difficult and harder to see the precise effects of one change over another. He has to be very, very careful to do tests that measure what he wants to measure, and not the effect of another variable altogether. Consequently, it makes a snake oil salesman's job (and I'm not suggesting anything about anyone in particular here) very, very easy. At the Buell race shop, we'd be very careful, and we also had a dyno mule that was closer to an engine stand than a motorcycle, with dyno-cell based cooling etc. And the later racing radiator systems eliminated a big cause of the interaction discussed above. The biggest power gain we ever saw from a pipe only change on a stock engine were with the Buell race pipe and the Termignoni full system, which Termi designed specifically with our race pipe as a comparison; both gave something like a 9-10 hp increase over stock, and both are very loud for street use (though Termi offered a restrictor which dropped noise substantially, and could be uncorked for track days.) | ||

Bueller4ever |

I could see you gaining 18hp if the bike was all ready running rich due to high AFV's. Then adding the pipe would lean it out. | ||

Bob_thompson |

Ken(Thurstonbuell), I like your idea, much like a two stroke uses on the intake side with reed valves, and I will add; as I have learned and verified by top tuners, the increase in pressure to the airbox only is recognized at very high speeds to be of any benefit, I.E. racing speeds above at least 85 mph and not much real H.P. gains until 150+. As a side note, at Bonneville some of those guys running intake scoops and either carbs or velocity stacks on F.I. intakes have seen way too much turbulence from air being forced across the intake stacks at high speed and many use a closed air box, but with a very large area for adequate air and intake air coming in from a remote area. Thats also different in drag racing where the duration of the "race" is too short to see this turbulence to any great extent. In NASCAR the pressure box is also shielded so intake air pressure is not "direct" to the carb. For very high speeds I would use the painted intake cover only without the inner one for a "still air box" and get air away from direct turbulence from the front much like Buell already uses. I believe they only used the inner air cover to stem EPA noise regs. I am using the original idea here, as you would, with a flapper valve, and there is no, or very little, turbulence to the intakes because of the wind screen. I have definitely seen an increase in mid-range performance w/no loss on top with this and my system. However I'm not at 10,000 rpm very long. One last thing I believe; for most riding, not racing, maximum H.P. is only one parameter as mid-range to about 9000 rpm's is much more desirable with most torque in that range and sometimes that does not produce max. H.P. at redline. How many of us run at red line very long? And if you do I do not think you will be riding very long unless on the track. Thats another story however. This is a very good thread and I appreciate everyones input. And thanks much to Highscore for a great idea that has proven out for me. Bob | ||

Dannybuell |

Highscore's science confirms the prior work of Captain_America. Thurstonbuell has extended this thinking with an all weather, low and high speed air pressure solution is simple and doable. :-) | ||

Dixopr |

So anyone else do this mod with success? | ||

Mountainstorm |

I've put over 500 miles on my 1125r since I removed the inner cover, lined the airbox cover with neoprene and removed the trim around the filler neck. It's added more low end response. I'm not streaking around at 150 MPH so I can't comment on top end performance. But it pulls hard up to 120 MPH and I can crawl up a gravel hill at 2000 RPM/13 MPH without the engine bucking. | ||

Prophet_136 |

i have also removed the inner air box and and, at first, cut out the trim around the fuel filler. this had great seat of the pants results with data to back it up. i ran a stock dyno run on the bike here in cali and at a ambient temp of 79 with lots of fans blowing it put down 132.7 HP and 71.0 ft,lbs. a few weeks later with an ambient temp of 81 and the air box mod she did 135.3 HP and 72.8 ft,lbs. i have since put on a XB12 air box with the stock air opening and screen, i have not dynoed the bike with XB air box yet. | ||

Kicka666 |

I have been running my 09 CR without the inner cover aswell as many BW riders too. I also relocated the IAT sensor. As discussed here before as I believe the factory location the most ideal to read correct intake temps. I took a different path in the location I mounted mine, being a spanner monkey I looked at all the riceys I work on & there IAT's especially the latest R6 it is mounted directly at the start of the ram air intake, in its new location it reads within a few degrees celcius of ambiant temps.    | ||

Mountainstorm |

I was thinking about trimming the part like you did, but I only have one part  and I would like the option of going back to stock. I've gotten some mesh to play with and I'm going to try forming it into a little screen for the opening. and I would like the option of going back to stock. I've gotten some mesh to play with and I'm going to try forming it into a little screen for the opening. | ||

Chevycummins |

Mesh kinda like this?   | ||

Mountainstorm |

Well I have that type of plastic mesh too, but I also have some steel hex mesh and some round hole perforated mesh. The hex has the most open area, but the round hole looks better. The way you did it looks a helluva lot better than staring inside at the guts of the airbox  I also need to find a stronger adhesive for the neoprene foam I lined the box with. It's losing tack from the constant heat. | ||

Dannybuell |

Kicka666 - Great Story. The new r6's placing the IAT directly in the ram air seems to confirm the argument for moving the Buell IAT sensor. Mountainstorm - gorilla glue? Mountainstorm,Chevycummins - where do you buy the plastic or stainless mesh at retail? | ||

Drawkward |

Kicka666: That's exactly what I was talking about. The stock location of the AT sensor borders on the ridiculous. Taking the inner cover off makes it even less of a real life measurement because the "sucking" effect at the opening is lessened even more so a relocate is needed. When I did mine I put it in one of the domes inside the airbox and have had good success with it. There is something to be said about taking the airbox cover off when racing the 1125R on the track. For a small track like GrandSport Speedway it is absolutely ideal as top speeds aren't over 100mph very often. However, at a track like TWS, it's not ideal as this modification limits you on the top end above 125mph. A better solution would be to have a bigger intake and keep the airbox cover as the 1190s and 1125RRs have... Dean, was that graph for the RT-3? | ||

Thurstonbuell |

Kicka666 , I like that , man now the wheels are turning ..... I found this too  Maybe a combination of the two ....hmmm | ||

Chevycummins |

I also cut out a piece of the upper cover just behind the mesh, put truck cap weatherstrip between the two covers and between the lower cover and the frame to keep out the engine heat. | ||

T_man |

If someone was to buy one of those aftermarket out airbox covers with ram-air scoops (they must however contact outside airflow) and cut an appropriate section from the inner cover to mate up seamlessly with the scoops - I believe you will have achieved essentially the best case scenario. Just my 2 cents. | ||

Mountainstorm |

For a piece of perforated metal try McMaster-Carr | ||

Kicka666 |

I will be putting alloy mesh on mine, just need to find some very small formable mesh, the stuff I had was a bugger to form into shape. | ||

Thurstonbuell |

So a quick re-cap , so it has been proven there is a benefit to removing the inner cover and opening the outer box cover around the fuel cap to allow more air in .... ? yes ? The majority who've tried and posted are pleased with the results ? I dont wanna be making mod's I cant reverse , so far everything I've done has been reversible , and I'm always hesitant to do the ones I cannot . | ||

Milleniumx1 |

Thurston, same here. I like knowing the pro's and con's (which this thread has been great in pointing out) and the various options. I can then decide if that works for me, and the ability to reverse the mod if I don't like it plays a big part in that decision. Mike | ||

Thurstonbuell |

Millenium , Mountainstorm sum's it up pretty well in the post "whos running air box with exhaust" . I guess I still wonder to some extent whether its the removal of the box , the opening of the neck , or its truly the combination of the two ... but thats me over analyzing like I always do I suppose | ||

Chevycummins |

The guys at ebr were testing some of these mods, they told me that just removing the air box cover let too much hot air into the intake. What they were doing was cutting the cover in half and only using the rear half of the cover, they put weatherstrip around the cover just behind where they cut it and that seals out the hot air from the engine. They just removed that plastic piece around the fuel cap. I just took it a step farther, only cut out the front of the cover and put a mesh piece in around the fuel cap. I wanted most of the cover on to keep out some of the water when washing or caught in the rain. I also drilled 2 small holes in the lower cover at the lowest point to help let some of the sand and water that may get in there back out. | ||

Mountainstorm |

Good ideas Chevy. It does get hot under the outer cover. I fan a digital temp sensor there just to see and the minute the engine warms up it's 15F hotter than ambient and gets even hotter when you idle. I'm going to try sealing up the lower part of the airbox to the frame and see if that helps. BTW while sorting through the shop I found some scraps of easily formed aluminum hex mesh. I'll be playing around with that too. Might have to mod that little trim piece. |