| Author | Message | ||

D_adams |

Just a few pics as it progresses. I had an hour this morning to play around some, snapped a couple of pics with the cell phone. I started it without any packing, it is EXTREMELY loud.        (Message edited by d_adams on March 07, 2010) | ||

Afhans |

D_Adams, Dude! Looks cool man! Ever think of doing a duel exhaust that splits hot air on both sides of the tire like that Free Spirits thing? I like how trier's looks but I will not buy it because of 1) cost (too much) 2) Turns a sh*ty colour after a few miles 3) folk say they don't seem to fit right. How loud are you going to make this one? would my neighbors hate me? | ||

D_adams |

I probably will do a dual can version eventually. Between building for customers and testing, I run out of time in a hurry. Not to mention, family, regular job at night and other side work I do. I've been doing computer repairs for 11 or 12 years now and I have a fairly well established customer base just from that. When I do get the time to build one out, it will be a 2 into 1 and back to 2 cans, probably 3.5" cans with 2" outlets to retain the sound I'm trying to get. As far as the neighbors go, I don't know how picky yours are, but mine haven't complained yet. None are over 50 though. I do get home at midnight, so if they were going to complain, I imagine they would have done so by now. | ||

D_adams |

Any commments on the outlet style? Yes or no? My wife is liking the slash cut better, but, pfffft, what does she know?  I'm leaning to the square cut myself, but I thought I'd ask for comments before I weld it on permanently. I can always build another end cap with a different style, but I've only got one plate for it right now. | ||

Ratsmc |

I am no expert on exhaust theory but I do know that when working on a bike a few years ago, the exhaust had an angle at the outlet similar to what you have on the outlet there. After not getting the results we wanted on the dyno, someone thought to change the outlet to a rounded curve. Improved flow dramatically and gave us more power. I think the exhaust flow hits that angle and has to bounce off of it rather than flow around a curve. | ||

Arcticcr |

I agree with Ratsmc, that the sharp corner on the outlet will likely have a negative impact on flow. Of course I canít quantify what the power impact would be. What about angling the whole pipe with a straight outlet? You could soak up the twist on the Y inlet side. On a different note regarding the Y, I'm still hoping that you make a longer runner primary pipes Y version. Do you have any plans to try making a different Y design? Thanks, Jay P.S. Mr. Adams, thank you for your creativity and your thoroughness in documentation in your post of your projects. Iíve really enjoyed reading the post. BIG THANKS! (Message edited by arcticcr on March 07, 2010) | ||

D_adams |

I agree up to a point on the exhaust flow theory, but that all went out the window with the stock pipe. At least 5 separate chambers. Reverse directions, heck, the first run down the middle slams right into a nearly flat plate at the end. I guess the angled tip may have an effect on it, but I'm thinking it won't be all that bad. Both the RT Type 1 and 2 have 2 chambers that do essentially the same thing, just not as drastically. I did want to use a 60 degree outlet like the others, I just simply don't have any more left in 2.5" stock. I will move the collector about 1 inch on the next one, but it will be shorter, not longer. I'll also be testing an X-pipe at a later date, but it won't be for a while yet, unless someone wants to pony up some cash for testing one. I keep a limited amount of stock on hand, but I'm pretty well depleted at the moment. All I have left right now is just odds and ends. My next shipment of material won't get here until Wednesday or Thursday. | ||

Ottobotz |

D_adams- -Cant wait till you get this RT III tested. I still think out of all the sound clips, yous is my favorite, followed by Barkers, and I really dont know what to think about the HR 1. The colors are cool, but there is already negative feed back on it. The sound is like there is no back pressure. -Have you worked on a price yet for the RT III? -Will you need a ecm and tune for it? | ||

D_adams |

The HR1 Riot has been around for a while, several have tried it, sold it, passed it on, whatever. I thought it sounded pretty good from the first video, but they kept changing the price on it, then the lead time for getting one went from 2 weeks to 4 or 5, so I waited for someone else to get one. I kept waiting after the first bad review, then finally decided to take matters into my own hands. Sure, their's might look better to some, but I liked the Buell race pipe first and then the Drummer. The Riot pipe would have been next in line if they had gotten a better review. The Barker pipe sounds a little higher pitched than what I prefer, but thats just me. It's different, and if it posts the claimed gains (without tuning as they stated) then it's a damn impressive pipe. 17 HP with no tuning. Well, I'm from Missouri, so I'll have to see it to believe it. They've got a lot of manufacturing capabilities that I simply don't have at my disposal, along with possibly an engineer or two. I've said it before and I'll repeat it here. I cannot compete on their level, fit, finish, volume or price. I do the best job I possibly can on every one I make, but everything I do is done by hand. I buy pre-bent tubing and pre-formed cans, but I'm the one responsible for where it really gets cut and welded at. I guess mine is more of a niche offering for people looking for either a very specific look or sound. No, it hasn't posted any gains yet, but as I continue to develop more options, who knows, maybe I'll hit that magic number and see a 20 hp gain with no tuning. It's not very likely, but it could happen. If it does and I gain anything at all, I will either replace or modify every pipe I've sold to match it at no charge except for shipping. I've got something I'm working on for it, but I won't know the results until I do more testing. | ||

Ratsmc |

Have you checked out local exhaust shops for bending and stock? I have glanced around online and the prices seem really stupid high. I have bought random bends from shops before as they often have stuff they can't use that is perfect for a bike exhaust. You may also be able to work out some decent pricing on stock since you are likely to be a regular. Plus, they can do custom bends. Just a thought, You may have already looked into it. | ||

D_adams |

Finding a local shop that does mandrel bent stainless has so far proved to be a fruitless search. I've got 3 suppliers for tubing at this time, so I'm good to go for the most part. Thats the biggest thing for me, the tubing must be mandrel bent. Finding the size I wanted turned out to be a little more difficult, but it's out there. I utilize as much of what I buy as I can with little waste material. Of the 2.5" tubing I buy, roughly 4-6" of material might get wasted, and it's just straight tube. All of the bends are used. It would be cool to have a tubing bender, but I think they start out at around $5000 or so and go up quickly. Plus you have to buy the tooling for each tube size. I've thought about it, but for such a small enterprise as mine, it would take years to recoup that expense. I can't justify that right now. Maybe when I retire and start doing these 60 hours a week, but not now. | ||

Jeepinbueller |

I still think it's one of the best looking cans (installed). Have to agree with the wife though Dean: I like the slash cut tip better  Good luck on getting everything ironed out. PS did you get my Email? | ||

D_adams |

Yep, got the email. I was just polling to see who liked it this way versus the slashed cut. It looks like the slash is starting to win and since I don't have it welded on yet, I will swap it out. I'm hoping I get it done by tomorrow, I'm running out of time. I'm wanting to put a few hundred miles on it but if it's not finished by then, it won't happen. I'll only get about 150 or so. PS. Happy Birthday. (Message edited by d_adams on March 08, 2010) | ||

Chevycummins |

Those HP numbers seem a little high for no tuning. I think the EBR race exhaust says up to 16HP with there ecm and exhaust. I'll test it soon. | ||

Ratsmc |

The issue, as I believe we found is that the exhaust "sees" that particular bend as a much smaller diameter than it is. forcing exhaust flow around bends or even into a flat surface to be refracted back can be useful and is how most factory exhaust dampen noise. However, the concern with that specific design is that it seems to actually diminish flow, not just velocity. Again, I am by no means an expert here so take what I am saying as you will, just trying to help out with the experience I have. | ||

Afhans |

D-Adams, looks like you know what you are doing. (Keep in mind I nothing about exhausts) So for anybody else interested, I found this link for exhaust info. http://www.mikekemper.com/elantra/diyexhaust/index .html | ||

Louisiana_xrider |

do ALL of your different mufflers use the same mid-pipe? I ask for the simple reason the i could buy, say the "ORIGINAL" muffler for daily commute, then maybe buy the round can or whatever else you come out with later, and interchange them depending on how obnoxious i feel that day? | ||

D_adams |

I didn't post those numbers, I'm just repeating what I had read earlier. I'm not calling anyone out on those numbers, I just find it tough to believe. Of course, I do not have the staff available to do what they do, I'm just one guy. The original intention was to build a repeatable collector setup to use in multiple applications, but it hasn't worked out that way yet. It could be done though. I bought the extra stuff just for testing and tried adapting it to the existing pipe. It's just that, a test. I'm not sure I'm even going to sell it yet. | ||

Louisiana_xrider |

I'm not sure I'm even going to sell it yet. I am guessing that the decision will come after the Dyno run on Friday? | ||

D_adams |

That and if I figure out an easy way to actually build this one to be re-packable. | ||

Louisiana_xrider |

just my 2Ę, but the tip looks to be in about a 5 o'clock to 5:30 position, I think it would look a little better in a 3:45 to 4 o'clock position. *unless that is just the way it is setting on the table in the LAST pic. (Message edited by Louisiana_X-Rider on March 08, 2010) | ||

D_adams |

Thats the beauty of these. I build it how each customer wants it. This one is for me, mainly just for testing it. I'm still playing with it. Unfortunately, I ran out of radiused tubing or it would have that on it, since thats my personal choice for styling. | ||

D_adams |

Different camera phone, audio quality isn't as good as the Nokia phone, I'll try to shoot it again with that one instead. It is loud since it's straight through, but not as bad as I had initially thought it would be. I'll be riding it for the next few days and have a dyno run scheduled on Friday morning, weather permitting. I think it's supposed to be clear though. | ||

Louisiana_xrider |

sounds alot louder ,than the twin outlet, at least by this video. | ||

D_adams |

In order of loudness, from quiet to loud, they go RT 1, 2 and then 3. It just worked out that way. Between the first 2, the single outlet is definitely quieter and more mellow. It may have been the type of tubing I used in the dual outlet, but regardless, the customer who ordered it was pretty happy with it. | ||

D_adams |

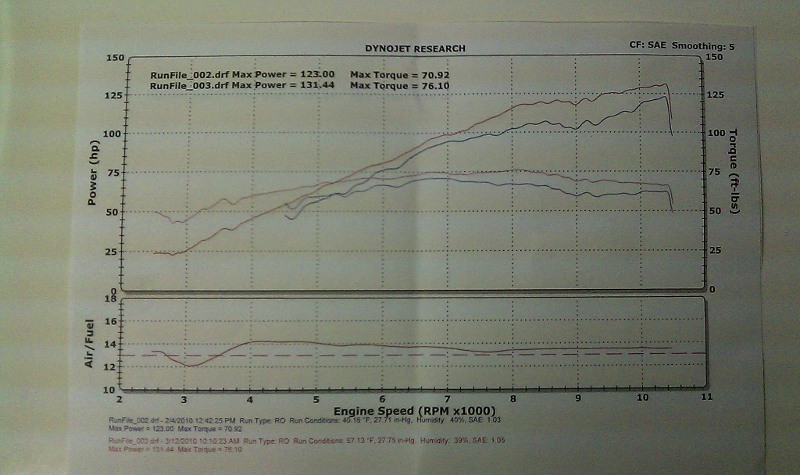

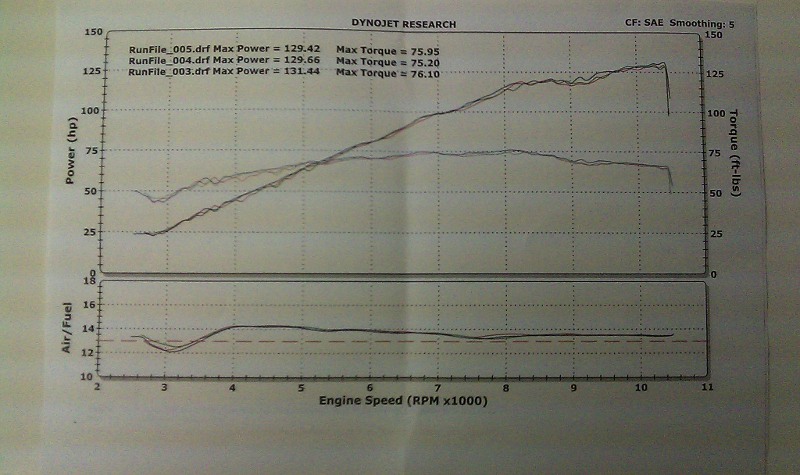

Stock run, 123 hp. RT Type 3 131.5 hp. NO TUNING. I'll get a pic of the dyno chart shortly, I got the overlay showing both. | ||

D_adams |

Dyno with and without the stock overlay.   | ||

Leechykyle |

That's a huge gain! Very impressive. Kinda makes me wonder why your other designs don't show any gains. | ||

Louisiana_xrider |

Have you made a decision on selling it or not? | ||

Firebolt32 |

I've been doing computer repairs for 11 or 12 years now and I have a fairly well established customer base just from that. You must not be repairing them very well! Kidding... Your craftsmanship of the exhaust is excellent! I can build things but damn, not like that! |