| Author | Message | ||

Bllueman |

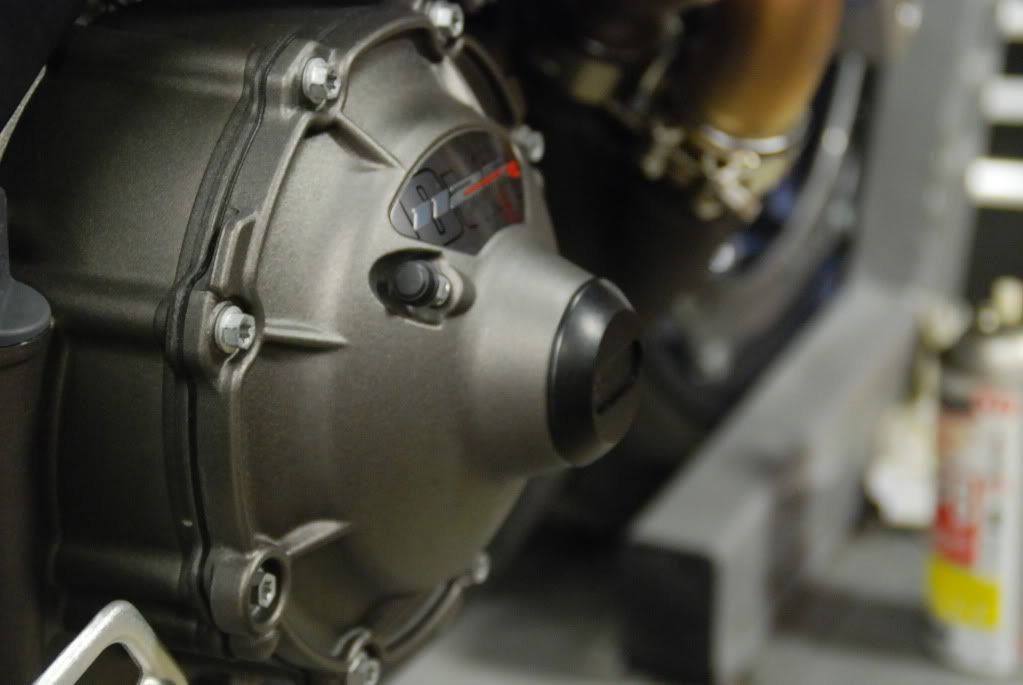

received my taylormade case covers yesterday. it takes about a week including shipping time. price for the 1125r/cr is $300 plus shipping. they just slipon using existing bolts on the engine covers. they are really trick looking, and hope i never need to find out how they work! | ||

Illbuell |

$300 smackers Ouch... They do look good though.. | ||

Rex |

The buell ones are 165 for the ring and 8 bucks for the logo. REX | ||

Xtreme6669 |

Rex they just pop in there... | ||

Westmoorenerd |

Yeah I'm not looking to spend 165 bucks on a small round piece of aluminum...I was wondering if there was any aftermarket ones yet | ||

Rex |

Thanks for the note. I assume they pop out also. I think the aftermarket ones are more expensive....REX | ||

Blur |

Blluman, where did you order them? I'd love to get some kind of case protectors. I don't care what they're made of I'd just like to have some extra assurance that the cases won't bust open. | ||

Bllueman |

blur: www.racetaylormade.com buell is not shown on their website but available. give them a call. | ||

Blur |

OK cool thanks. I was just searching their site and didn't see anything so I'll give them a call. Thanks. (Message edited by blur on February 04, 2010) | ||

Nillaice |

http://www.badweatherbikers.com/buell/messages/290 431/465597.html | ||

Blur |

I just got off the phone with Kristy and ordered a set. Nice lady and these look like quality parts. | ||

Nillaice |

i was gonna order a set last paycheck, i asked some one else nicely to make a few. | ||

99buellx1 |

Yes please. I also would be in for a set of aluminum ones if someone were to make some. | ||

Wkd14u2 |

Taylormade have them back in stock, I just got off the phone with Kristi and ordered a set. a mate in the US is taking delivery and dropping them to me when we next catch up.. i'm posted in asia at the moment, so cant ride anyway, plus it save custom charges getting it sent to the UK  they look like good stuff and cant wait to fit them. Wkd1 | ||

Hdwrenchtx |

cool. i was thinking of ordering another set earlier today | ||

Rex |

the photo of the product looks good. Is the carbon fiber strong enough? or would it be destroyed along with the case slider? | ||

Froggy |

Carbon makes a great slider....  | ||

Illbuell |

Thats why the knuckles in gloves are carbon | ||

Nillaice |

i think it's on gloves just for looks. if it is functional, i'd think it'd be on the outer edge of the palm too. | ||

99buellx1 |

No, functional. Outer edge of palm would be an issue becuase it's not flexible and would be extrememly uncomfortable. | ||

Puzzled |

These are from Grand Stand Designs (site sponsor) which we sell through Ebay. This is a re-post from when they were initially installed. The clutch case saver is for the Rev A cover only. I have spoke to Pete about a Rev B case saver. I recently installed a set of Engine Case Sliders. They are made from T-6061 Aluminum and are .10" taller than the OEM plastic sliders. The install is pretty straight forward as the OEM pieces pop off with a small regular screw driver. Next up you remove the factory O-ring and install it on the new slider. I added a little lubricant to the O-ring to make pressing back on the bike easier. Once seated I used a dead blow hammer and tapped the cap lightly to insure that it was seated (didn't want to loose my nice new caps). http://cgi.ebay.com/ebaymotors/ws/eBayISAPI.dll?Vi ewItem&item=190337696581&viewitem=&sspagename=STRK %3AMESELX%3AIT Here are the factory plastic sliders.   | ||

Puzzled |

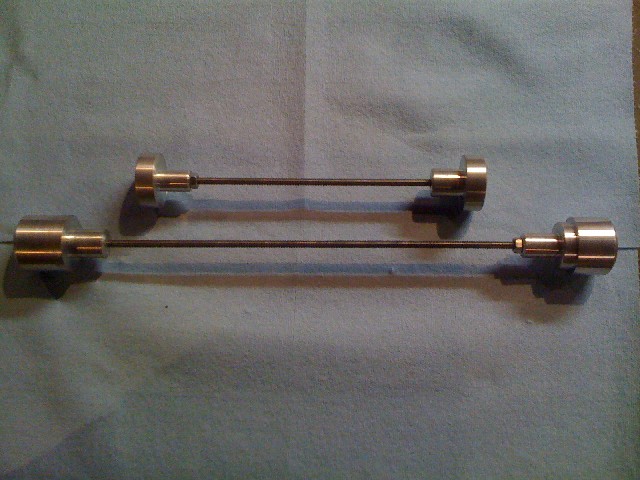

Replacement sliders.   Difference in height from old to new sliders.  | ||

Puzzled |

Clutch side installed.   | ||

Puzzled |

Stator side installed.   | ||

Hogzilla |

Puzzled, those are a great option. I'd be all over them for the Rev. B covers. I'm guessing for a high speed dump they'd be toast, but for a low speed oops, they'd probably work fine. | ||

Puzzled |

I believe you are correct. I have a motor here that slid on asphalt and the slider and cover are WORE down! From the looks they were the stock covers. | ||

Westmoorenerd |

I already has a set of GSD sliders, worked for a 25mph low side. My case still ended up getting scratched, but it only took out one rib...I can't imagine what would have happened with the dinky plastic ones. I just need a Rev B cover though since I'm NEVER going to pay the crazy price the factory wants for it. | ||

Blackflash |

I was bored yesterday so I bought a 5'chunk of 6061 T6 aluminum,some 304 stainless threaded rod and went at making a set.They look awesome. I've had prior machining experience so this was a quick wip up.       | ||

Blackflash |

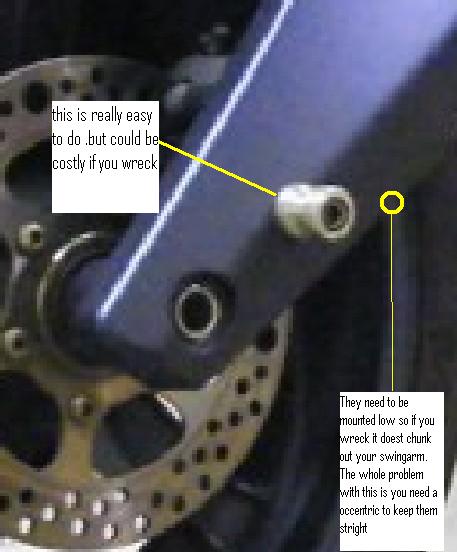

Last year I had a low side slide out on some gravel.Needless to say my swing arm took a beating.That's why I made these.I just picked this lathe up and will be making myself bar end sliders and a newer designed lift spools double lipped with a eccentric to keep them straight on the swingarm when mounted low. Ive seen drill in style lift spools on her that were made.I just don't like how high they were mounted.They need to be mounted low like the 09s in the event of a crash so they don't brake .Thats what sliders are for.The problem is the swing arm has a angle on it so everyone drills them right on the body line to keep the mounts straight.This is a big no no .In a wreck the mounting is high and it will cause you swing arm to grip on the pavement or dirt and chunk the arm out.Like I stated thats what the ridgid axle sliders are for.Chunking has already been documented and talked about. Heres a pic I made a set of 6061 t6 aluminum shifter pegs also with my new lathe.Thier longer for positive shifting and braking.      | ||

Dannybuell |

Blackflash; Hmmmmmmm. how much to make another set? dannybuell |