| Author | Message | ||

Skully |

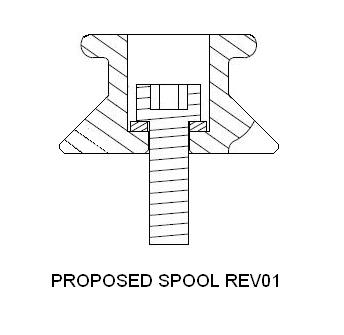

I managed to con, um, obtain the talented help of 1324 (aka Nick) to help with the design of the DHM lifting spool. His expertise with Pro/E and owning an 1125 really helped out. Nick modeled the OEM spool and then based on the feedback that we received from you, designed a replacement spool that was both compact and reduced the possibility of scratching the swing arm when the forks of the wheel stand are inserted:  Here is what the solid model looks like:  Now that the collective has had time think about this, please take a few minutes and give us feedback on the design. Again, you are in the driverís seat here. Our goal is to supply you with the parts you need. The plan is to provide them in aluminum that has been hard black anodized for appearance and durability. Unfortunately, I donít have feedback on the 1125 EcoSliders yet as the tester had a family emergency. But itís safe to say that we will make sure that the DHM 1125 EcoSliders protrude past the lift spool by a sufficient amount to protect them. Thanks for your time, Keith DarkHorseMoto, LLC | ||

Ds_tiger |

IMO Hard to fault the "bobbin" technology- (captive the stand- no scratch the swing arm)- my thought would be to find the "sweet spot" for typical (Lockhart Phillips & Pit Bull) stand finger/fork thickness and leave a 1/8" play on either side (spool design) Looks good! | ||

Froggy |

I'm in for a set, regardless of whether or not I will ever use them. Hell in 3 years I haven't used the spools on my XB yet.  | ||

Stevasaurus |

Is there a "standard" width between the lift points? The first thing I thought when I saw the section views side by side is that the offset would be an issue, no matter how beneficial the intent of bobbin is. Keep in mind that I don't own a set of stands (yet) so if my question is completely bogus, I respectfully withdraw. | ||

Dwiggs |

As long as they fit the Pit Bull stands, I'm in for a set. | ||

Skully |

DS - We elected to keep the spool as compact as possible to reduce the chances of it ever making contact with the ground. My concern is with the cast aluminum swing arm coupled with a very thin threaded boss could be easily damaged in a crash. Froggy - Thanks! Steve - All of the swing arm stands that I'm familiar with have a wide range of adjustment. The two in my shop have at least an inch of adjustment per side. Dwiggs - Shouldn't be a problem. Keith | ||

Avc8130 |

Keith, Is there still an aluminum insert, or are these completely aluminum? I am sure Nick told you (if you didn't know already) Delrin will creep and fail in a spool application. ac | ||

A_s_r |

Looks good! Assuming they work with the most common rear stands (Pit Bull, T-Rex, Vortex, etc.) they should be good to go. My only suggestion would be to add a couple of degrees of draft on the lead-in for the spool groove. | ||

Squarecircle |

Greetings from San Diego; >>>> Apparent to me is the need of a more stoutly bolt fastener as opposed to the rather small 6mm. standard issue. The contact base does not provide a large enough diameter of solid contact to resist a good glancing hit,in the event of a lay-down, thereby bending the smallish fastener. However this could be a good weakness, perhaps saving the swing arm from bending forces.>>>> Rambling on. sq. | ||

Dwiggs |

Squarecircle, my impression is that these are intended to be used in conjunction with more robust axle sliders (which would take the impact forces in a crash rather than the spools). I'll be ordering those as well when the spools are available. In fact, I'm hoping to see a nice package deal offered (including the front axle sliders as well, if possible). | ||

Ft_bstrd |

I wish I had a bike to put them on.  | ||

Blake |

Avc, In Keith's post above... "The plan is to provide them in aluminum that has been hard black anodized for appearance and durability. " So "all aluminum" is accurate. | ||

Spaceman |

Looks good. Assuming they'll fit a Pit Bull stand, I'll buy a set. | ||

Xtreme6669 |

I'm in for a set when A package is ready, I too would want the front and rear sliders and the spools. | ||

1324 |

ASR, good idea on the draft. That will be easy enough to add, and there is plenty of meat. As long as Keith and his machinist are OK with it, I can add it. Squarecircle, the 6mm bolt was used so that the spool replaces the stock spool and mounting provisions. Steve, the groove width was optimized to accomodate common spool lift plate thicknesses. There won't quite be 1/8" on each side once lifted, but only because (as Keith mentioned), we wanted to keep the spool as compact as possible to prevent crash damage while still protecting the swingarm during lifting. And yeah, Anthony...all Al. | ||

Cwadster |

My Pit Bull stand doesn't fit the spools that came on on my 1125. The swingarm is too wide--even at max width. | ||

D_adams |

Cwadster - use a 3 ton floor jack to spread it apart about one to one and a half inches. It's just tubing, it will bend without breaking up to at least three or four inches. It got bent to get to the shape it's in now, bending back a little won't hurt it any. | ||

1324 |

^^^ This is what I had to do with my old Handy stand....but I did mine by hand since it was just a bent loop. The Pitbull stands look to be a bit heavier duty. | ||

Avc8130 |

I read and re-read that post and didn't see aluminum before I posted. DOH! ac | ||

1324 |

Don't worry, we won't fault you for your 3rd grade reading comprehension skills...lol. | ||

Avc8130 |

I goed to publik skool at NJ...the superintendent taked all the money that were suppota pay me teacherses. So when will these spools be available? Hard anodize is a good choice. I had some other spools in the past that were plain anodized and the finish wore quickly. ac | ||

Freight_dog |

I also spread out my standard Pit Bull stands. I still have the adjusters widened out most of the way. Jeez this swingarm is wide. Works like a charm though. Those spools look great Keith. I would say they are precisely what the BWBers have asked for. | ||

Blake |

Suggestions to consider... 1. Deepen counter-bore (hide screw head} 2. Widen base then taper it towards slot to help guide rear bike stands into place and better protect swingarm from stand. 3. Minimize length of protrusion, flat form instead of rounded head form.  If needed, clearance/relieve base outboard of faying surface to avoid interference with swingarm surface. | ||

Avc8130 |

Blake, Your design does not leave much aluminum to actually support the bike. You have very little bearing surface on the bolt shank unlike the designs proposed above. ac | ||

Dwiggs |

For what it's worth, I prefer the look of the rounded design. The visible screw head doesn't bother me. | ||

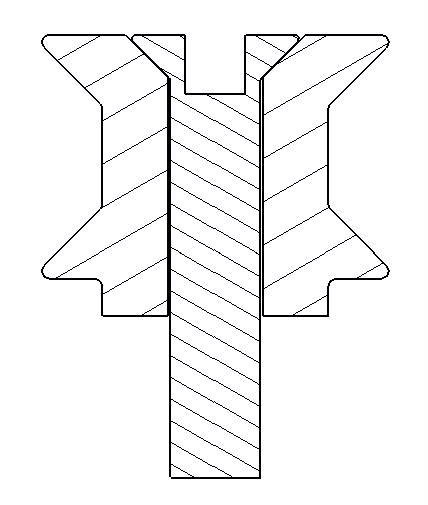

A_s_r |

I see what Blake is getting at, and I like the direction he is going. The "buttonhead" style design leaves a lot of material that isn't adding to the functionality of the design, which is to guide the rear stand into position, support the weight of the bike, and protect the swingarm from damage. Some suggestions for Blake's design would be to add angled lead-in to the outboard side. I would also suggest changing the socket head cap screw out for a shoulder screw, which would help bear the weight of the bike. If I have some time this afternoon, I will model something up to illustrate my suggestions. | ||

1324 |

Blake, 1. The counter bore depth was chosen to maximize cross sectional area under the lift point. I also do not like the bolt being visible, but it is a small price to pay, and now it can be as short as possible. 2. Wider flat base won't clear the swingarm due to the way the boss is welded from the factory. Hence, the little step on the 'bottom'. 3. Rounded head was chosen for aesthetics (same radius as stock) I added drafts to the groove over lunch today. I'll let Keith review and post if he likes it.... | ||

1324 |

Some suggestions for Blake's design would be to add angled lead-in to the outboard side. I would also suggest changing the socket head cap screw out for a shoulder screw, which would help bear the weight of the bike. I'd recommend not using the fastener to bear the weight of the bike. Even the lowest grade M6 bolt will provide enough clamp force to rely on the spool. It is nice to avoid loading fasteners in shear whenever possible. Additionally, it would be nice to retain the same fastener head size as stock for maintainability. | ||

A_s_r |

Alright, here's what I could get away with at work  It's probably not to scale as I'm not sure what the dims were from the stock spool. I also went with a flat head cap screw, rather than the shoulder screw I referred to earlier.  | ||

1324 |

Not a bad approach, IMO. I thought about a flat head cap screw but opted out for a few reasons. Looks nice. I guess it comes down to looks and what people prefer. |