| Author | Message | ||

Gotlime |

Was it neccesary to insult the guy while disagreeing with his staement? | ||

Froggy |

Could the slider shape/design be a factor? Possibly road surface? Like a sharp edge on the slider hitting a poorly repaired crack, hooking onto it causing the flip? (Just speculating) | ||

Avc8130 |

Froggy, No personal crash experience, but I have installed my fair share of sliders and evaluated quite a few others that were "tested". Plastic sliders seem to provide the best OVERALL coverage. They absorb impact and abrade nicely along pavement. They will also shear when required. This is important. A scratched swingarm will be better than a bent swingarm/axle if a large enough impact occurs (sliding up onto a curb or into a pot hole for example). I will choose a delrin slider when available because I FEEL this fits MY needs best. ac | ||

A_s_r |

Keith, here's what I envision for a swingarm slider & spool package, at least for the 2009+ 1125 models that come standard with a spool. A slider very similar to the DHM003 Signature Series Stealth Slider that protrudes past the stock spool, such that it would take the impact in a slide, rather than the *weak* stock spool. No need for it to serve as a lift point, as that is what the spool is for, especially when changing the rear tire. Additionally, it would be nice to have a better constructed spool that has wider base inboard of the lift groove (similar to the T-Rex and GPI spools) that would capture the hook on the rear stand and prevent the hook from scratching the swingarm. Of course, it wouldn't need to be as long as the offerings from T-Rex & GPI, as it will not be taking the impact in the event of a slide. | ||

A_s_r |

Guess I should've done a little reading first  At least I was on the same wave length as Keith! | ||

Skully |

It seems that you guys want an improved OEM spool for lifting and an axle slider for protection. Now the question that must be answered is what are you willing to pay for the improved lifting spools? If $25/set is number, I can't compete with the mass produced items that are universal fit. We do use state of the art CNC lathes and mills, but the problem is still the limited quantities. I simply can't afford to run hundreds of parts only to have them set on a shelf if they don't sell. We will have a low cost rear axle slider kit available as soon as I get feedback (should be towards the end of this week). Do you also want a Stealth Composite slider kit for the 1125 series? You guys are in the driver's seat here. Let me know what you want. Thanks, Keith | ||

Avc8130 |

Keith, What type of dollar value do you project? I have paid $35 for high quality swingarm spools in the past. If your product is better than the competition to warrant the increased price I will buy it! Honestly I am looking for the $100 shipped "total protection and maintenance package" for my 2009 to include spools and front and rear sliders. Feasible? Close? ac ac (Message edited by avc8130 on December 01, 2009) | ||

Skully |

Anthony, What you propose is an interesting idea. An EcoSlider kit that has the front and rear sliders and spool lifts in it with hardware may be doable for $100. I'll have to design the spool lifts and get quotes. Keith | ||

Avc8130 |

Keith, That is exactly what I am looking for. I think with the rapid influx of 1125 owners you will find quite a few people looking for this package also. ac | ||

Blake |

Apparently some idiots might read this conversation and imagine that we are talking about frame sliders. | ||

Blake |

"I'm posting this from a satellite manufacturing clean room where I am surrounded by more carbon fiber, titanium, and advanced composites than you are likely to see in your lifetime." Let's hope that helps improve your cognitive powers. I don't put much stock in the possibility though. I've seen too many posts from you spouting nonsense about BadWeB and other stuff. If you don't like the rules here or being told that your statements are idiotic, you are free to depart. If all you want to do is whine and cry about how the place is managed, you really should avoid the place. If you need help with that, we're happy to assist. Either stick to discussing Buell motorcycles or take a hike. Your choice. I sure won't waste any more time answering your pathetic whining. | ||

Naiguy |

Skully, please make Eco crash protection system! I want one asap | ||

A_s_r |

Considering the Stealth sliders are in the $60 range (which I've happily paid in the past for DHM's high quality products), if a slider & spool package could be put together in the $80 range, I think it would be a hit. | ||

P_squared |

Dude, go for a ride already. Spend some time over some cold ones with friends. Do something other than carping here about how Blake runs his playground. | ||

Blake |

Trying to use the lifting spools as sliders on a Buell 1125 is the perfect way to severely damage the swingarm. It would be really idiotic. | ||

Blake |

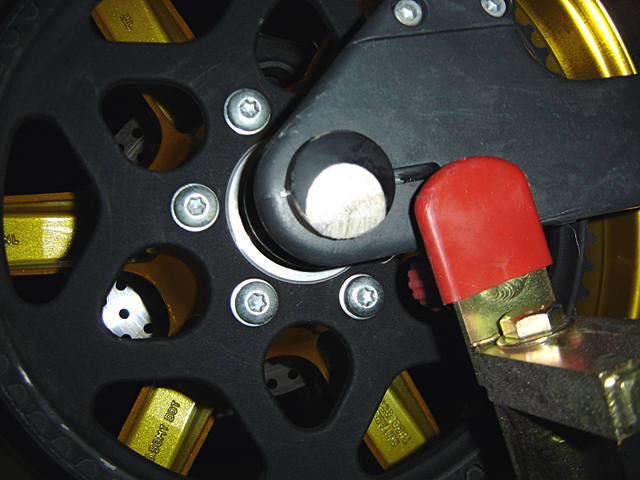

Ooh, look, a spool! And a plastic slider! Just like the DHM product pictured earlier in the thread. Another false idiotic statement. The DHM sliders are axle sliders that are robustly fastened to the rear axle via 5/16" steel rod and a very strong embedded/captured mechanical connection at the axle on each side. It's strength is light years beyond that of any tiny little lifting spool attached to an aluminum swingarm. | ||

A_s_r |

^^^ I can attest to that. My wife had the unfortunate chance to test one of DHM's sliders on her XB. It undoubtedly saved the swingarm, and likely kept the bike from being a complete total. (Message edited by a_s_r on December 01, 2009) | ||

Skully |

Fred, Would you post a link to the Motosliders 8 mm Swingarm Sliders? Regarding aluminum sliders, I can show you photos and testimony from our customers where the sliders performed perfectly with no tendency to grab. I am absolutely not trying to cover all instances, only the ones that I have knowledge of. Obviously, you have experienced something different and this is why we offer sliders made of Delrin or aluminum.   As far as the swing arm goes, my 25 years of mechanical engineering design and manufacturing experience along with as many years of motorcycling and several years of racing tells me that putting a tiny threaded boss near the edge of a cast swing arm and then attaching a cantilevered slider to it is asking for trouble.  Can I quantify this opinion? No. Can I discount what happens when a Japanese bike goes down with similar sliders and does not damage the swing arm? No. I would want to study the design of these Japanese swing arms and know what materials they are made of before forming an opinion. You could have two identical motorcycles crash in a very similar manner and one might have minor damage and the other could be totaled. The dynamics of a crash are very unpredictable. Let me know what you think. If most of the owners are going to bolt on existing commercially available spools/sliders, then there is little point in me pursuing this. I have products that I need to be finishing up. Thanks, Keith | ||

Avc8130 |

Keith, I still think a nice package with a spool just big enough to provide a locating lip on each side to protect the swingarm/provide side to side location and a set (front and rear) of sliders would sell well for you. There are literally 100s of new 1125 owners who are probably looking for this type of package. Price it right, allow it to be configurable (different slider materials/options) and I think you will get some sales. Throw a Badweb 10% package discount price on there and I think you will get LOTS of sales! :-) ac | ||

Speedy818 |

Working around Fred here - I too would be interested in this $100 package for protection and function - please count me in! | ||

Blake |

Only an idiot would make the leap from such dubious internet commentary by a person trying to sell something to the conclusion that the tiny footprint of a lifting spool attached to relatively thin aluminum swingarm, let alone a cast aluminum swingarm, does not put the swingarm at significant risk of damage. The truth is that it's a really, really, bad idea. | ||

Blake |

... putting a tiny threaded boss near the edge of a cast swing arm and then attaching a cantilevered slider to it is asking for trouble. Absolutely 100% astute, 100% accurate and the very crux of the issue. It is glaringly obvious to me--what do I know, I'm just a stress analyst--that the cast aluminum lifting spool attachment bosses are not designed to withstand crash induced forces transmitted by any slider, delrin or otherwise. Mounting a slider to that tiny little cast aluminum boss would be really, really dumb. | ||

Avc8130 |

I see some ANSYS in someone's future. Put the argument to rest with some good new-fashioned engineering and pretty colors. ac | ||

Blake |

A pencil and paper or a spreadsheet would suffice. The analysis is the easy part. Coming up with accurate design loads however, not so much. | ||

Avc8130 |

Sometimes the analysis is what you need. Then you know the failure stress. Once you have that we can poke around and mess with stuff. F=ma could be used to determine loading in an impact accident with a certain weight bike at a certain speed F=muN could be used to determine friction forces. Mu would need some research. N can be determined with gravity and bike mass Analysis could be done. Is it worth it? Depends how bad someone wants to shut the other side up! Easier solution: Short spool/long slider ac | ||

Blake |

You have a good start. What values would you use for "m" and "a"? One likely failure mode would be the steel screw being ripped out of the tapped aluminum hole due to bending and heal-and-toe prying action. Another would be the fracture in combined bending and shear of the screw itself or possibly the aluminum boss. The frictional lateral load would peak at impact, so it'd likely be a LOT greater than just F=Mu*W. The only "easy" solution that I see is to avoid using the tiny little lifting spool to try to support a slider. Use the axle for that. (Message edited by blake on December 02, 2009) | ||

Avc8130 |

M could be the mass of the bike since it SHOULD be alone by that point...rider is most likely long gone. A is the "variable". In a tip over, gravity will be close enough. In an impact with a curve you could use Speed/time and assume time to be a VERY short quantity. Obviously this is all possible as every major car manufacturer does this stuff to determine crashworthiness. Agreed you would have to overcome STATIC friction first. I agree whole-heartedly in the spool for lifting, axle for sliding/impact...I was just stating that it IS possible for one side to prove the other side more right or more wrong with enough work. ac | ||

1324 |

Re-subscribing since my subscription keeps running out. Glad to see we've learned to play nice and discuss some of Newton's finest work. My vote is for short spool and a longer axle slider as well. | ||

Skully |

My vote is for short spool and a longer axle slider as well. Short spool in work. Do you want/need the current DHM axle slider to be longer than it is? Keith | ||

Avc8130 |

Keith, Do you have an 1125 to test fit on? If not, can you provide dimensions for the slider? How far past the axle does it protrude? What length will your spools be? ac |