| Author |

Message |

D_adams

| | Posted on Thursday, October 15, 2009 - 12:19 am: |

|

I think on the stock pipe, we should be able to get away with maybe 6" long 1.5" OD stainless pipes. Cut off the stock tips, open the can from the top, peel it back, cut away the 1.1" inner tubes for the stock outlets, clean up the rust, open the holes just a bit more and insert the 1.5" pipes, then weld into place. I think the slash cut would work with the right angle. Also, are you wanting to use thick (.080") or thin (.045") wall tubing? |

Redscuell

| | Posted on Thursday, October 15, 2009 - 01:16 am: |

|

What Prophet_136 has done with the '3rd Pipe Option' has the LOOK of what I had originally intended (thanks for the acknowledgement  ). Very nice-looking result on Prophet_136's part. ). Very nice-looking result on Prophet_136's part.

Ultimately I went with a slash pipe to direct the sound more outwardly.

Important: that '3rd Pipe Option' must be substantially larger than the first two to produce a worthwhile result; they're only 30mm o.d. inside those s/s shrouds. The original pair are a total of less than 2 square inches in area; while the pair of headers (44mm o.d.) and the backbone internal main pipe (63mm o.d.) EACH have areas of 4.5 square inches: more than double.

I originally put in the smaller pipe that it appears that Prophet_136 has used (not so nicely formed, tho) because I was thinking I was going to unleash a torrent of noise and perhaps actually LOSE performance. Instead I got a buzzy sound and no 'felt' performance change, up or down. I was disappointed.

So next day I had my chap put in the full-sized 48 mm o.d. (1.75") tubing that I had wanted to start with. Seat of the pants went up, sound turned into that 'thump' that we've been expecting.

Dyno says the power and torque went up significantly when compared with other graphs posted on the Board (torque equal to claimed, for example). But I did not dyno it beforehand because I hadn't been willing to pay $100 to have the less-than-advertised power & torque proven! It was only after I 'felt' an increase that I took it to the local dyno for evidence yay or nay. |

Tbenson

| | Posted on Thursday, October 15, 2009 - 01:38 am: |

|

Found this exhaust clip.

www.youtube.com/watch?v=g0zrHt8bgbM |

D_adams

| | Posted on Thursday, October 15, 2009 - 01:54 am: |

|

Interesting sheetmetal muffler there. Wish the video quality was a bit better, or maybe a link to better pics even. |

D_adams

| | Posted on Thursday, October 15, 2009 - 02:09 am: |

|

Just checked the 1.75" pipe to see what it looked like next to the stock pipe and it would be an extremely tight fit to get both into the curve, but it just might go in.

I can get 1.25" 1.5" 1.625" and 1.75" pipe, as well as larger sizes. 1.25 is too small really. 1.5" would probably fit best into the curves, but the ID will be around 1.35" so there's not a lot of flow gains. The 1.625" will most likely be about 1.475" and the 1.75" is about 1.6" ID, but it would be the tightest fit. Of course, this is going by the heavy tubing thickness. |

Tbenson

| | Posted on Thursday, October 15, 2009 - 02:16 am: |

|

The same guy modified a D&D.

http://www.buellxb.com/buell_images/4693_200908270 80527_L.jpg. |

Blackflash

| | Posted on Sunday, October 25, 2009 - 11:05 pm: |

|

Ive been reading alot of post on the issues the 1125r and cr owner have delt with.One major issue is the can

that leaves a dirty soot on your bike.I recently purchased a jardine to try it.I completely hated it.Ive come to a conclusion that not one exhaust manufacture has harnessed for what im looking for.

1 A pipe that wont blow the packing out.

2 That wont blow my eardrums out.

3 Doesnt change Eriks underslung design.

4 And of course one that requires you to hand over your paycheck and more.

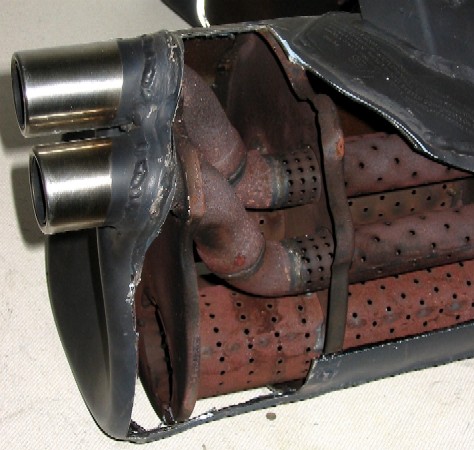

Ive had time to hack my share of these cans up and realized that nothing beats this can!!! And everyone says its not worth researching .I believe everyone that is selling pipes wants you to buy a muffler that is made of precious metals with a exotic price.

Starting to scratch my head again and say why can't someone offer a service.The service would be to knock off the SS side tubes and reweld them on a 45 degree angle.This will keep the wheels/parts clean. Next add a few db & not a full blown eardrum blowout.After all this If wanted powdercoating/jet hot coating at a good price!!

Im here and Im working on it.I have plenty of good hardworking americans that have small bussinesses around me.Some powdercoating can be seen on my R.I got rid of my 08 blues.

Ive been a fab/welder for over 10 years now.

I have the tools to do this .I just believe so far Im not happy with anything Ive seen or heard.I know this bike is newer and companys are sceptical on if they should persue this bike and fab something up.Well since the bad news and the very small amount of these bikes produced I believe that there will be fewer pipes developed .Thank god cause they all suck!!

If anyone is interested in services contact me. Ive had enough of these mediocre pipes that dont impress me.Right now I will be looking into sound quality that doesnt disrupt the powerband of the bike.Im not here to build a racepipe.If that comes about great!

If this sounds good to you or if you are interested in what im aiming for please pm me.Im not looking to take your paycheck either.

After getting my wheels freshly powdercoated on my 08 r I decided to take care of the soot issue.Now im off to discover tolerable noise. |

|