| Author | Message | ||

Reepicheep |

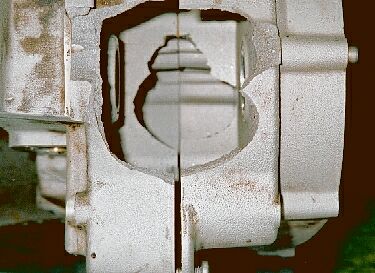

This was discussed by a number of people in the quick board, but I think it ought to be here. Anyway, thanks to painful lessons learned by others on this list, I decided to pull the oil pump on my 2000 M2 (about 10k miles) and check the drive gear for the oil pump. Sure enough, look what I found:  So... I am assuming this is badly worn, and should be replaced. Though I post the picture here so wiser and more experienced folks then I can weigh in. I hate to pull the cam cover if I don't need too, but I would much rather spend an evening replacing a $15 part then trash an engine I am otherwise very fond of. So what does everyone think? Should it stay or should it go? And now I have a new line for "you know you own a buell when...." You know you own a Buell (and frequent badweb) when... you are wiping 20w50 off your nikon coolpix. Thanks in advance. ESPECIALLY to the people that took the time and trouble to post the heads up and get me to pull this apart and look at this before serious damage took place! Bill (Message edited by hans on July 17, 2006) | ||

Reepicheep |

Attn Layfayette! You asked if all the failing drive gears were associated with oil pump part PN26204-98. Mine (pictured above with 10k miles on it) was PN26487-98. This was on a 2000 M2, around 10k miles, the last 5k or more of which was run on full synthetic. Never abused or run out of oil. Bill (Message edited by hans on July 17, 2006) | ||

Reepicheep |

Worn Oil Pump Drive Gear.... Putting a little more info together. First of all, I unfortunately named this knowledge vault entry wrong. The problem is not the pinion gear, but rather the drive gear for the oil pump. If there is a moderator that could change it that would be great, if not, well, it's only one gear off  The original discussion (thanks EricX1 and Spudman) can be found on the quick board at Quick board entry. This is the discussion that made me vaguely uneasy. Ever since my broken exhaust header stud experience I have been trying to be very proactive on my fixes... The thing would have been a pretty easy proactive fix... an hour to install an updated front mount... but is a terrible reactive fix... probably 10 hours of sweat, power tools, broken bits of metal, and blood in the garage. The oil pump drive gear was the same but even worse. About 45 minutes from start to finish to remove, inspect, and reassemble if things are fine, potential catastrophic engine damage if it is NOT fine and you ignore it. I won't know for sure how bad mine is until I pull the gearcase cover, but that wear visible in the lower left hand corner of the above shot makes me pretty nervous. I suspect the gear would have held up for another 5k miles or so (there is about 10k on the bike now), but who knows. Waiting for it to fail is NOT an option, unless you hate your oil pump and cam gears. Here is the first round of parts I will be ordering... I will put an update here if it turns out I need fewer or more. All descriptions are relative to my 2000-2001 cyclone parts manual (PN 99572-01Y) 1) Gearcase Gasket Cover, Page 15, Index 12, Part number 25263-90C 2) Drive gear - Oil Pump, Page 15, Index 17, Part number 26318-88A 3) Square Key, Page 15, Index 8, Part Number 11317 I will post prices as well after I get back from my local Buell dealer. Anyone want to bet the only part they actually stock is the square key?  Bill | ||

Nevco1 |

Question...Should the oil pump gear be replaced with another from the same factory or would an aftermarket part be better? In essence, did HD upgrade the part or are you just replacing it with another part with a short life expectancy? | ||

Reepicheep |

In the previous discussion, somebody found a better bronze / silicone replacement part from Zippers, but upon asking found out it was discontinued. I will see if the new part looks any different then the old part. I have no idea what the original part number was, all I know is what my '01 parts manual lists. I will ask them at the dealer if there is a revision history in their system. Otherwise, I guess you just add it to your list of 10k miles maintenance items..  | ||

Blake |

I'm wondering if there is some form of misalignment upon installation that might contribute to excessive wear on some of these gears. There are no instructions for any kind alignment check/procedure upon install of the pump, right? | ||

Reepicheep |

Nope. no alignment instructions, though the way the thing mounts (two allen head bolts and a gasket) there is not much of a way to align it. Here are the sum total of the installation instructions: 10. Secure pump to crankcase with mounting screws (4). Tighten to 125-150 in-pounds (14.1-16.9 Nm). 11. Attach feed hose (1) and oil filter hose connection (5). 12. Attach clamp to hose. Interestingly, didn't somebody a while back note that the number of gears on each were an even multiple, which means a particular tooth pair always meets? I wonder if "rotating the oil pump" every time you "rotate the tires" would change the rate at which it wears? If you look at my shot above, it is clear that the wear is worse on one tooth then others. The pump comes out pretty easily, you just have to remove the shock resovior and a couple allen head bolts. And just to further reenforce my cynical nature... guess how many of the parts on my above list the local "Buell" dealer had in stock  (Hint... it starts with a Z). Not even the gaskets.... (Hint... it starts with a Z). Not even the gaskets.... | ||

Reepicheep |

Blech. Pulled the gearcase cover off tonight. Had to pull the entire exhaust of course. I got it off without removing the heads with a lot of patience and wiggling, but I doubt it will go back on that way. And now I need to scare up a 1" deepwell impact socket to try and get the nut off without spinning the tire. Blech. Any way to relieve the pressure before reassembly without removing the heads? Thats gonna add at least two hours to the job. On the upside, if you can call it that, the oil pump drive gear was a lot worse then it looked in the picture above, and was getting pretty bad. Had that gone it would have been a lot more expensive a job (though perhaps not much more work). | ||

Blake |

Bill, Here's what you need to do, trust me on this... Go ahead and carefully remove each cylinder head. Find a bunch of that bubble wrap stuff, wrap each head securely in the wrap and then with packing tape. Enclose in a box, send box and some of your money to Cycle-Rama or Nallin Racing... You get the picture, right? ![:]](http://www.badweatherbikers.com/buell/clipart/proud.gif) | ||

Aaron |

As much as I like Blake's suggestion, you don't need to remove the heads to get pressure off the cams. Only the rocker boxes. 'Course, at that point, and with the exhaust already off, you're pretty close to having the heads off. | ||

Reepicheep |

I barely got spousal approval for the used supertrapp I just got... my karma is already burned! But no argument, that would be the right thing to do! So unless the Nallins or Cycle-Rama need some software development / web development / electrical engineering / networking / system security work, that ain't gonna happen. I barely got spousal approval for the used supertrapp I just got... my karma is already burned! But no argument, that would be the right thing to do! So unless the Nallins or Cycle-Rama need some software development / web development / electrical engineering / networking / system security work, that ain't gonna happen. And actually I do plan on sending money to one or both of those companies eventually, but I think that will be on the used XB9S I buy 4 or 5 years from now for $5000. I will keep my cyclone about like it is and ride it until they bury me. Replacing that oil drive pump actually is getting into quite a bit of work... Pull the exhaust system, remove the shock resoviour mounts (not the pressure line), pull the oil pump, pull the heads, pull the cams, replace the drive gear, reassemble. Thats all straightforward, but its a LOT of wrenching. In my case, it is not a huge deal, I had to pull the exhaust to put on the supertrapp anyway, and I still have initially replacement paper gaskets in the rocker boxes, so if I have to pull the rocker boxes its a job that I will have to do sooner or later anyway. But still... this is a LOT of work for a $15 part. But inspecting the oil pump drive gear is pretty easy. The amount of work you save by discovering a worn one is not much difference then the amount of work done once it grenades (so long as the crank is not damaged), but the costs are hugely different (single $15 part instead of new oil pump, new cam gears, probably $600 or so). I was going to ask how you know where in the four stroke sequence the engine is at to line up all the cam gears, but I figured it out that it does not matter, so long as the crank is keyed for the pinion gear, and that is aligned with the four cam gears, then it does not matter if you engine was on the intake or exhaust stroke when you took it apart. Too cool! I love the mechanical beauty of these engines. All the more so now that I have had them apart. I can't say the new more reliable XB's are a bad thing, but there will definitely be a special part of the whole ownership experience that is lost by not spending time inside the engine. There is something artistic about the elegance of these engines... a snorting, snarling, rolling sculpture that only a engineer* can really appreciate. Bill (note I use the term engineer broadly... I have an engineering degree and I know first hand that the correlation between "engineers" and people with "engineering degrees" is weak at best, and by no means can be demonstrated to be a causal relationship  ) ) | ||

Nevco1 |

Anyone have a clue what a dealer would charge to replace the drive gear as well as the drive gear and oil pump? | ||

Reepicheep |

Got the part out. I will post pictures tomorrow. It was not quite as bad as it looked on the above shot, the really scary looking part in the lower left corner must have been a drip of oil, as I can't see anything that bad now that it is out and clean. But it is definately badly worn. I probably would have gotten another 5k or 10k out of it before catastrophic failure. The wear is definately assymetrical as well... there is one particular tooth that has worn to be REALLY narrow across the top, and some that are barely worn at all. I can see the one that would likely have failed first. Assuming the previous poster (have to check the archives to see who made the observation) who noted the number of teeth are such that each always hits the other was right, that could be a big part of the problem. On all the failed units, once they fail I imagine they would proceed to trash most of the remaining teeth, so it would be hard to tell the difference between just one tooth failing and all failing. So maybe a once every 5000 mile rotation of the oil pump is in order. Drop the oil pump, rotate the gear a half turn or so, and slap it back up there. It would be a quick and easy job. | ||

Nevco1 |

Reep...Just a note to let you know that I am really enjoying your posts concerning this subject. Preventative maintenance and replacing failure prone parts is of utmost importance to me. Unfortunately, being mechanically declined, I have to rely on someone else to do the work. Thus the occasional naive (or is that Evian) questions. Thanks again for the narrative. | ||

Jrh |

Reep,does your oil pump drive gear,after removing the nut and pinion gear,seem kinda loose(as in wobbly on the shaft) ,like the i.d. is bored a little too big?On my 2000 M2,at just 350 miles my oil pump drive gear(the helical gear on the crankshaft) had 4 consecutive teeth that already had,i guess what you would call"polished spots".I did'nt have an inside micrometer to compare the bore of the gear with the crankshaft o.d.,but i recall being surprised that the fit seemed a little loose,now i'm wondering if some of the wear problems could be being caused by this.Maybe some gears are loose on the crank,thus when the nut gets tightened down at assembly,the gear might not be centered on the crankshaft. Unless the small(driven) gear on the oil pump is a harder material it seems like it would wear a lot faster than the drive gear,you probably want to really look at it close. | ||

Reepicheep |

The oil pump gear looks ok, but wear there would not be as obvious. I don't recall a sloppy fit when I pulled the helical gear, but I will go back out and check. I threw calipers on the gear. The least worn part narrowest point at the crown of the gear is .062 inches. The most worn narrowest point is .042. This is all on the same gear, from a 00 M2 with around 12k miles (as I recall). Inside diameter of the removed gear is .631 inches. Naturally, the local Harley / Buell (typical "one blast on the floor Buell dealer) still has not gotten parts. First, they were due in yesterday. Then they were due in today. Now, they say they will be in next week. I think this is the last time I waste time with them. They did not stock a single part, not the key, not the gasket, nothing. I am about to buy a first and third gear pair, and probably a Baker smooth shift kit (or at least a new shift drum). I will take my business to a badweb sponsor, hopefully one of them actually stocks parts, and can ship in a timely manner. I will try and post some pictures of the worn drive gear later today for any mechanical types to review if they want to. Like I said above, it was not as bad as it looked during inspection, but it is badly worn. It would probably go another 5k miles easy, or 10k miles before being totally used up. But I have it this far apart so I might as well replace it. | ||

Reepicheep |

YAY for F&S Buell, in Dayton Ohio. On the down side, it was about an hour drive one way. On the upside, it was sunny out, my 5 year old son came with me and we had a nice drive. Not only did they have every last part I needed IN STOCK, but they also knew exactly what I was talking about when I said "and throw in a couple of those new firebolt rocker box gaskets"... the parts guy replied "you mean the metal ones, right?" It was like a breath of fresh air. So I have the new and old gear side by side, and there is a significant difference. First, the newer part is 1.191 inches in diameter, the old one is 1.192. More significantly, if I try and mesh the teeth, they are WAY off, and the interference pattern suggests the exact wear marks I am seeing on the old part. Let me see if I can get a picture....   Any mechanical types here have any ideas about thread pitch, etc? They look way different to me. Bill | ||

Reepicheep |

The square key was $.85, the rocker box gaskets (metal) were $5.50 each, the gearcase cover gasket was $3.75, the oil pump drive gear was $15, and the exhaust seals were $5.15 each (ouch!). The oil pump gear was a harley part. You also need a few small hose clamps for the oil lines. I am going to try and put it back together without removing the rocker boxes... It will take me about two hours to pull and replace both, so it is worth spending about half an hour trying to do it without pulling them first. Bill | ||

Littledog1 |

Bill, I also want to thank you for your documenting the oil pump gear issue. Of course, before you started this I wasn't worried about my oil pump drive gear. Now I am...out it comes next oil change. On the plus side, I have wanted to cut down the cam cover, so this gives me the nudge I needed to get with it. Thank you, Mickey | ||

Reepicheep |

Geesh. You experts out there did not warn me what I am getting into!!! The jobs are pretty straightforward, but it seems I have this entire bike apart. To pull off the cam cover, you have to remove the shock resovior, and pull the exhaust. OK, fine. Oh, and you have to drill out the rivits on the timing cover, and pull that all apart as well. Remove the oil feed lines of course. Oh, and pull the oil pump. Then you are supposed to ***dismantle*** the deutsch connector on the other end of the timing wire so you can pull it under the starter. WTF? (by the way you don't have to, you can just work on it propped up on the bike with a milk crate). Oh yeah, and to get the cams back in, did we mention that you have to remove BOTH rocker box covers? Geesh. I have the garage filled with little bits of cyclone. But the jobs are easy. They will take a LOT of time, but they are easy. As it turns out, the drive gear probably would have lasted for another 5k to 10k miles, but I had a cam in very bad shape, so it was a good thing I tore it down. | ||

Littledog1 |

Bill, Your excellent thread on your oil pump drive experience hooked me. I kept thinking 'I better check that gear'. I also have wanted to cut down my cam cover, so I decided to do both at the same time. Of course, like all projects this one took longer than it should have. Removed the exhaust; unplugged the ignition sender leads (not easy, mine was trapped under the starter)and disassembled the connector; drill ignition cover rivits, and remove cover; scribe and remove sender; remove cam cover, with the cams left in place; inspect the oil pump gears (both look good!); attack the cam cover with sawz-all, grinder, and emery cloth; reverse the process to re-assemble....piece of cake! Only took be 10 hours, but I feel better now. Thank you, Mickey | ||

Reepicheep |

Littledog... Wonder what makes you so special  You have 12k miles on a 98 and your drive gear is in perfect shape, my 00 with 12k and the gear is about half baked. Hrrumph. You have 12k miles on a 98 and your drive gear is in perfect shape, my 00 with 12k and the gear is about half baked. Hrrumph. Interestingly, the first replacement part I got (from a dealer stock) had a small nick in one end, probably chipout from the cutting tool (it looks just like every wood joint I cut with the router does when I am done  ). When I got the replacement for the replacement, that was fresh from the factory, the packaging was different. Don't know if the pitches were any different. ). When I got the replacement for the replacement, that was fresh from the factory, the packaging was different. Don't know if the pitches were any different. If any factory lurkers want the old gear for analysis, email me a postal address and I promise to mail it and promptly burn all records and eliminate the address from my memory (which happens by default as a general rule anyway). | ||

Reepicheep |

And just to wrap this topic up... here are my thoughts on the job. Just inspecting the gear is a breeze. Cut a cable tie, remove an oil line, remove the shock external resevior (a worm clamp and a nut), and drop two allen head bolts (SAE). The oil pump then wiggles down and out, and you can crawl under and get a nice view of the trouble prone gear. Have a replacement gasket ($.89) and some gasket remover, and all your normal oil change consumables. There is speculation that the number of gears on this pair is an even multiple, so the same teeth always mate. I definately had assymetrical wear on my gear. When you do the inspection, rotate the oil pump gear 90 degrees before you put it back in. Viola! New life for old parts. You could probably do the whole oil pump removal, gear inspection, gasket removal, and reinstall in an hour if you were in a hurry. To actually replace the gear, you more then likely will need to remove both rocker boxes to get the cams back in. Its an easy job, but it takes a lot of time. People claim to have done it without relieving the pressure, but I saw no prayer for making it happen. Harley makes a locking tool (a plate with teeth cut into it) that would make removal of the crank nut a little easier, and judging by the look of it it should be cheap. Alternately, if you put the bike in fifth, hold down the foot brake, and hit the nut with a rotary impact wrench it comes off fine. Installation is also then a 3 hand affair, but you can do it. You will need the full rocker box gasket kit for both cylinders, a worm clamp for an oil line, some teflon tape, the crankcase cover gasket, and the oil pump gasket. You will also need a couple of those magic rivits that hold on the timing cover, and the timing plate screws are pretty easy to strip so consider getting a couple of those just in case (or be more careful then I was). You also (duh) need a new oil pump drive gear, and a new key. You also have to pull the exhaust header, so consider getting new exhaust gaskets. The manual shows how to line all the cams back up, it is a pretty cool process. The whole rocker box part takes probably twice as long as the crank case and cams part, which is a real shame. Otherwise, it would be a really easy job. The manual wants you to actually pull apart the deutsch connector for the ignition pickup, as the cable is captive under the starter. I simply used a bungee to fasten the crankcase cover to the frame, supported it with a milk crate, and left the wire attached. You only have to drill a couple rivits and remove a couple screws, so it can be done while still teathered to the bike. As it turned out my gear was probably only about half dead, but who knows when it would have failed. It also turned out I had some damage to my number 4 cam (front exhaust), that was unrelated to the oil pump gear. If the gear did go, it could easily chew up the oil pump and the cams, which would turn a $15 repair into a $500 repair. It could also chew up your crank, which would turn a $500 repair into a $1000. Fired it up and it ran great. It was a satisfying job, though the rocker box part was a little demoralizing at first. Ironically, my gear was still servicable, but I found a bad #4 cam and a little rocker box leak starting, and I was installing a new supertrapp, so all the "extra" stuff I had to do was stuff that needed to be done anyway. It was even time for an oil change, which also has to be done when you pull the pump. So thats it! Feel free to email with any questions. Time wise it was not terrible, like littledog said maybe 10 hours or so at a pretty liesurely pace. All said and done the parts were not expensive, maybe $50-$75 overall. The rocker box gasket kits were more expensive then the replacement drive gear. Don't attempt to reuse the oil pump gasket, no matter how perfect it looks, even if you do put yamabond on it. It *will* leak  . The gasket is the same as the Sportster part, so your dealer may actually stock it. . The gasket is the same as the Sportster part, so your dealer may actually stock it. And a huge thanks to everyone who bothered to post their stories of oil pump gear problems. You probably saved me a failure with a repair I could not afford to make right now. | ||

Anonymous |

This topic is worth keeping alive , as the following pictures are worth keeping alive , check your oil pump drive or you may one day face this ....................................     | ||

Steveshakeshaft |

Ouch! Steve steve_s@ukbeg.com www.ukbeg.com | ||

Reepicheep |

Wow! Thanks for taking the time to take and post those pictures! Thats scary stuff... that top one reminds me of the aftermath from the scene from Aliens where the thing comes out the guys chest! Inspecting these things is REALLY easy! | ||

Renter |

Anyone have some ideas how and why these gears wear so different at diff. mileage. Latest info i found was that the conical bearings in the crankcase are a bit out of their workrange on our buells. these bearings are said to have an upper workrange of 5000 rpm. edit: checked bearing specs with SKF and Timken bearing speedrating 10,000 rpm with oil lubrication end edit: This is also believed to be the reason why the conical bearings are replaced for needle bearings in the XB engines. (crankshaft) An other explanation i got was that flexing of flywheel assy causes misalignment. This together with conical bearings and usual high rpm running might be worth investigating a bit further. I would like to find a possible explanation we can all live with. All thoughts and info welcome. Rgds, renter edited by renter on January 20, 2004 | ||

Lake_bueller |

With my motor pulled for my S1W project, it looks like I need to do more work than expected. It will definately be easier to do this work with the motor out of the bike. Thank God it's the middle of winter. I have nothing better to do than wrench  | ||

Sportyeric |

With 85k miles, the Sportster is being rebuilt. A rattle that may have been lifters got me into the cam cavity. The drive gear on mine has teeth with a knife edge!!!!Looking at Reep's pic at the top of the thread, half way between his two arrows, the top of the tooth is flat, with a bit of cross-hatching visible. Mine is razor sharp on the top of each tooth. Pump gear looks fine. I wonder if they should be replaced as a set. Puts a new meaning to "matching wear patterns." For the record: original equipment oil pump, rarely revved beyond 5500 (though frequently to there.) | ||

Hoser |

Eric: Change em out as a set if you can afford to , this is an oportunity to upgrade to the 98 style pump. The gear on the pinion shaft is the one that always wears more quickly , when new the profile of the gear teeth is similar in appearance to an acme screw thread , sharp teeth are a sign of doom and BIG repair bills. | ||

Sportyeric |

I'm finding it interesting that this is the only significant wear that I'm finding in the entire engine, save for a valve stem seal that started this project. I'm tremendously impressed with the durability of the whole package. Reflecting on the cause of the wear, I picture the main pressure on the pair of gears being when the oil is cold and thick. I'm not very good at warming the thing up in the driveway, preferring to just putt away and leave the neighbours to get back to sleep. Is this worth idling in the driveway til the oil thins out? If that's the cause? Probably not. Reeps wear/mileage ratio matches mine. From .062 to .042 in 12k miles. That extends to my .062 to zero in 85k in a fairly linear fashion. Anyone else? | ||

Banditx |

Are there any problems with the Oil Pump Drive Gears of the XB Buells? The parts are the same like in the RR Buells. | ||

Whodom |

Bandit, Someone posted this question in the XB forum a week or two ago. As far as I know, no XB oil pump gear problems have been reported. It appears that the gear mesh, which is determined by the vertical position of the oil pump, could be the root cause of the problem (see Whitebuell's post). If this is true, it may be that the XB engine cases are machined slightly differently to correct the gear position and so the problem doesn't occur. | ||

Reepicheep |

What whodom said. The parts "architecture" is arguably fine, many many Sportsters and Buells using the parts have absolutely no problem. No evidence at all of a problem on the XB's. And even if there is an issue, if you find it before it breaks, it is not a huge deal to prevent the damage. |