| Author | Message | ||

Puzzled |

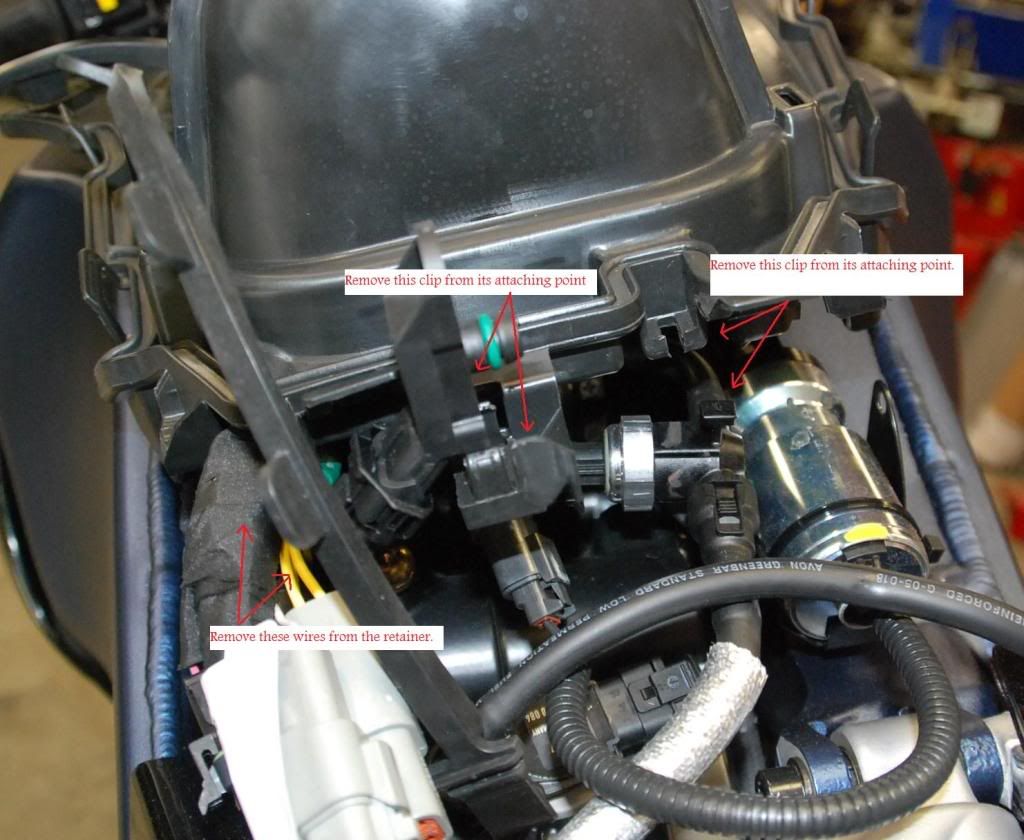

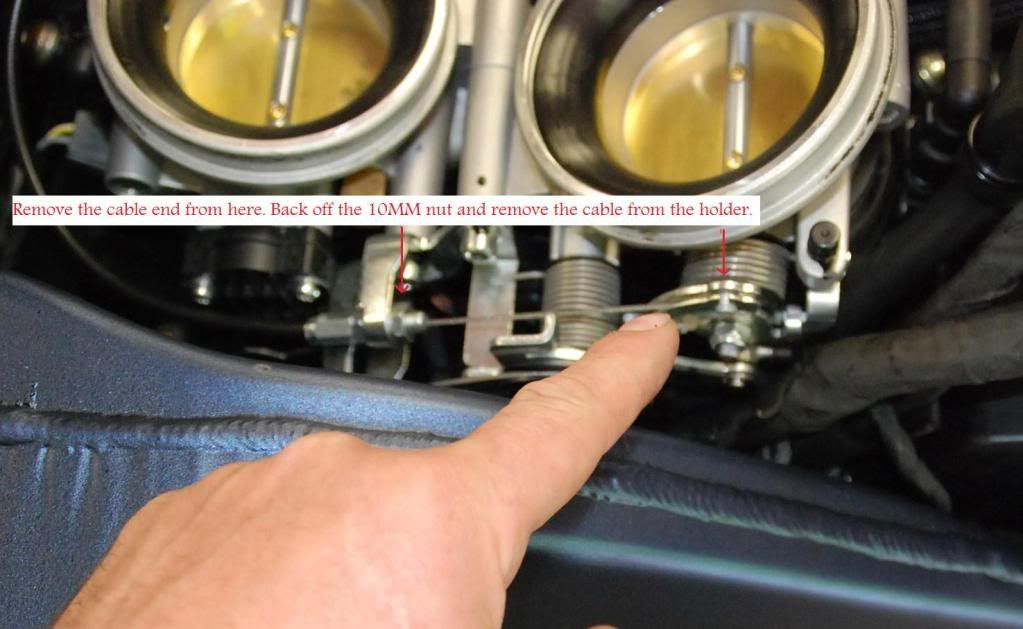

Here is a brief tutorial on how to "De-noid" an 1125. 1. Remove seat ,2 torx screws under the rear corners of the seat. 2. Remove outer air box cover ,4 torx screws, two along side the gas filler, two at the rear of the cover that the seat covers. 3. Remove the fuel overflow hose from the air box cover. 4. Remove inner air box cover, several plastic clips around the perimeter. 5. Remove air filter 6. Remove air filter holder, 2 torx screws, two wire connectors, wiring harness, vent hose. The assembly pulls off with a little bit of resistance. 7. Pull cable out of butterfly attach point. 8. Loosen 10MM jam nut to allow the removal of the cable from the holder. 9. Unplug solenoid at wire harness connector. 10. Insert resistor into plug in wire harness. 11. Remove two 5/32 allen head bolts from solenoid. This will allow access to the torx screw that holds the solenoid bracket to the frame. Remove torx screw. 12. Remove the solenoid bracket, solenoid and cable. #5  #6   | ||

Puzzled |

Overall view.  #7 and #8.  #9 and #10.   | ||

Puzzled |

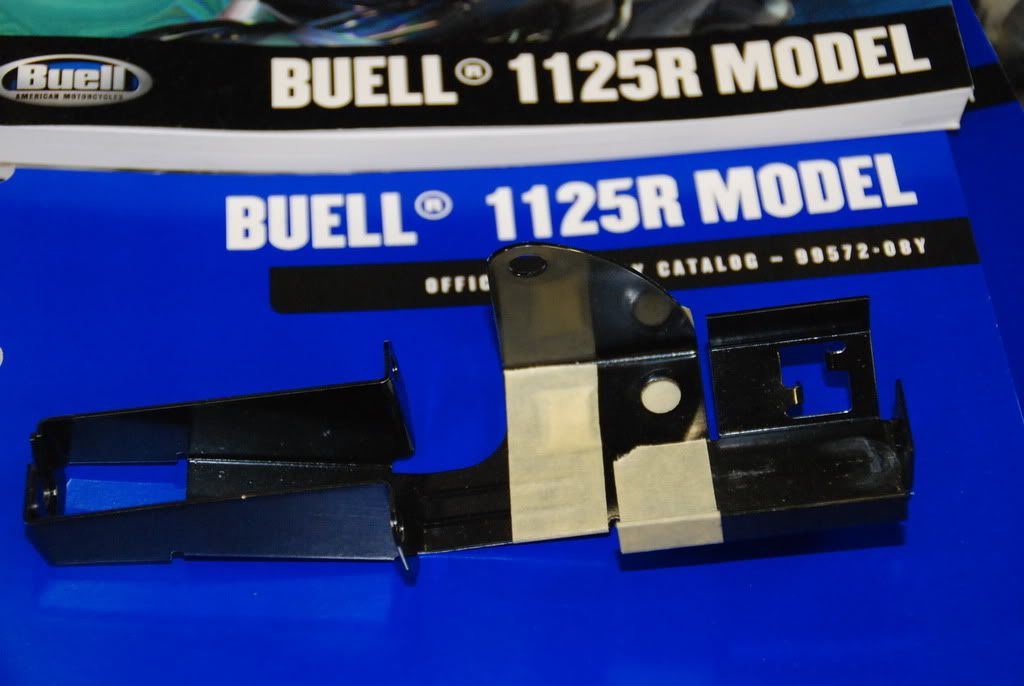

#12.  I zip tied the linkage together.  | ||

Puzzled |

While I was in there I made the bracket as suggested. The tape lines indicate where I am going to cut.  | ||

Puzzled |

A little time on the table sander, a few squirts of black paint and it is good to go. Installed.  | ||

Jake99buell |

De-noid awesome! Why no race parts? I figured it was EPA issues. | ||

Spaceman |

Tha't EXCELLENT Puzzled. That will make my de-noiding a lot easier. Thanks | ||

Johnnysunami1967 |

You're an amazing man Puzz. Knowledge and photo-shop! Hero! See you in Millville NJ 9/4-9/6!!! | ||

Bigblock |

Excellent documentation there, Puzz! | ||

Blake |

Outstanding Puzz! Thank you! | ||

Chadhargis |

What did you cut and reinstall the bracket for? | ||

Puzzled |

That was done so there was a place to bolt the rear right hand corner of the air box cover to. What did you cut and reinstall the bracket for?} | ||

Chadhargis |

Humm...I didn't do that, and mine went back together just fine. Maybe I missed something. I'll double check next time I'm in there. | ||

Avc8130 |

You can just remove the actual solenoid portion of the noid and leave the whole metal bracket. ac | ||

Puzzled |

I didn't like the look of the bracket without the solenoid in it so I cut mine. I installed the air box cover initially without the bracket and had no idea that it was free floating until a fellow forum member told me it was. Sure enough I looked and the air box cover was screwed to the air box but nothing was holding it to the frame. | ||

Avc8130 |

Ok, I lied...4500 rpm, 3rd gear and I wacked it WOT. CEL bright and blazing. So what does the resitor actually prevent/resolve? ac | ||

Chadhargis |

The resistor keeps you from getting a persistent CEL that never clears. | ||

Electrobuell |

Sorry if I am completely behind on the issue... What is the benefit of removing the solenoid? | ||

Avc8130 |

Well that is important too. Remove the solenoid so you don't get a bike that dies flat on its face when you go to accelerate briskly in 3rd gear. ac | ||

Lastonetherebuys |

I took my noid off last night. Thought about cutting the bracket but then desided that why bother seeing as you wont see it. I just wrapped a zip tie around where the end where the cable uset to attach to the solenoid so that it wouldn't vibrate against my frame. I hate vibrations that dont belong! | ||

Sparky |

Anybody know how strong the pull of that solenoid is? I mean if one holds the end of the cable in one hand, can they can keep the barrel end of the cable from pulling in? I'm thinking that if it's strong enough to move the mechanism, I might be able to use it to lock/unlock the driver's door lock button on my '65 Dodge Dart that has a broken key lock. Recycle good parts,... it's good for the planet! | ||

Chadhargis |

I was thinking about using it to automate something too, just don't know what. It appears to be a dang nice solenoid. Wonder if it's variable, or on/off? | ||

Avc8130 |

You could make it one of those squid plate flippers! LOL ac | ||

Jaimec |

Is that why he suggested cutting the bracket? To avoid a buzzing noise? Makes sense... I was wondering why he didn't just bolt the thing back into place as is so you had the fourth anchor point for the airbox cover. | ||

Frontline |

I just did this to my bike yesterday. I dont understand why you need to zip tie the old solenoid linkage. It seems like once you remove the solenoid the linkage isnt going to move any more. can you explain why it is necessary to tie up the old solenoid linkage? thanks | ||

Froggy |

Perhaps it can be rigged to lift up the seat? No longer need those stupid torx screws.  | ||

Avc8130 |

Froggy, You need to get a quick release seat kit. ac | ||

Ponti1 |

Frontline, the idea of hooking them together is "just in case" one could become out of sync with the other, or even worse if one were to get stuck in the open position. | ||

Frontline |

Frontline, the idea of hooking them together is "just in case" one could become out of sync with the other, or even worse if one were to get stuck in the open position. If comming out of sync or getting stuck in the open position were a problem would this not occur also if the noid were hooked up? Considering the spring keeps the linkage in the off position. Maybe I am wrong but do you see the rationale. if the is no problem with the noid on why would there be a problem with it off. The noid only pulls it does not push that is what the spring is for. Is there anyone that can get into more detail. If there is some good insight here it would be nice to know. I dont particurily tear the bike open again for no reason or crash because this zip tie is necessary. thanks | ||

Puzzled |

Is that why he suggested cutting the bracket? To avoid a buzzing noise? Makes sense... I was wondering why he didn't just bolt the thing back into place as is so you had the fourth anchor point for the airbox cover. I could have left the factory bracket installed but simply didn't like the looks of the complete bracket as it looked like something was missing}. By cutting the bracket down it is small and does the intended job. |