| Author | Message | ||

14d |

Pretty sure this is the stock gear, but not positive. Can you guys tell from these pics? I'd rather not go into the gear case unless I have to.   Previous owner installed cometic rocker box gaskets everywhere but the front lower rocker box (where it was leaking), guess he didnt want to have the fun of pulling the front one off.  Also what are the chance's of being able to reuse the seal on the crankshaft behind the CPS? Anyone got a PN for it? | ||

Phelan |

I don't have a P/N, but if you look up a '00 Sportster on Bikebandit.com, you can look through the diagrams and find it, then cross the number on the diagram with the number below the page for the P/N. | ||

Preybird1 |

That has to be the stock gear it is not bronze! I would not re-use any gasket. | ||

Buellistic |

The Part Number for the High Performance Oil Pump Gear(BRONZE) PN 26391-06 ... Checked my DRIVE GEAR at 60K miles and looked like brand new, "BUT" "i" still replaced it with the -06 gear ... Replaced it because a RACING part is always better than the stock part ... IMHO, my OEM gear lasted because "i" have a return line oil filter(pictures if you want them) which means any metal in the oil goes through only one side of the oil pump for a reduction of 50% oil pump drag ... Other wise any metal goes through the return side of the oil pump to the oil tank, from the oil tank to the feed side of the oil pump, and THEN to the oil filter ... "ALSO" my PRIMARY CHAIN has always been adjusted correctly at 3/4 inch on the chain tight spot(NEVER TOO TIGHT) ... Used H-D 20W-50 DYNO OIL for first 60K changing every 2K miles, then went to H-D 20W-50 SYN3(change every 3K) to the current mileage as of the last ride of 108,359.3 miles ... MAY THE LONG LASTING BUELL BE WITH YOU !!! | ||

14d |

Yep, it's the stock gear. Now I can't get the pinion gear off, FSM says it should slide right off but it's stuck on there pretty good. Any tips on how to get it off without effin anything up? FSM says only to replace the seal if it's leaking or damaged, looks good so I'm not worried about it. Rivet's are such a pain in the ass, I messed my timing cover up pretty good getting them out. That's ok, I wasn't to crazy about the flaming skull anyways. Definitely will be switch to self tapping screws on the reassembly. Thanks for all the help guys! | ||

14d |

One more thing, am I correct in assuming I can use the CPS reading in ECMSpy to set the static timing rather than a breakout box and multimeter? | ||

Buellistic |

Replace the "RIVETS" on the timing cover with SCREW,screw self tapping H-D PN 2662W from your local H-D Dealer ... | ||

Drhacknstine |

YEP, ithe procedure is in the TUNING GUIDE  (Message edited by drhacknstine on August 17, 2009) | ||

Easy_rider |

I was in a similar situation, and kept the stock gear since it did not appear to have any adverse wear. The problem is that some gear sets did not align well, resulting in spline wear that eventually lead to a spline breaking off. My theory is that the bronze gear would wear worse. Got one for sale if you want it.. As far as removing the pinion, it seems like it took me a little effort, too. | ||

Sportyeric |

I used a gear puller and put a penny over the shaft so it wouldn't split the shaft. That doesn't mean I know what I'm talking about, but it did get it off without harm. Put a good dent in the penny. | ||

Reepicheep |

You need better pictures, and from a few different engine rotations, but from what I can see that gear is fine and there is no reason to replace it unless you plan on racing. | ||

Brinnutz |

I'm with Eric...I used a gear puller carefully. | ||

14d |

Got the bronze one in and got it all put back together. I was able to get the pinion gear off by putting the short part of an allen wrench between the two and GENTLY prying. I was thinking a gear puller or maybe battery terminal puller, but it came off pretty easy, just had to be a little more persuasive. The stock gear wasn't showing any wear, but the bike only has 9.2k on it and the bronze one gives me peace of mind. Dunno about racing, but I'll be going up to track pretty often in the future. Just waiting on the penske, gotta do the intake seal and she'll be good to go. Oh, and some new springs and gold valving up front in the near future. One thing I did find kind of odd is the FSM didn't call for any threadlocker on the screws holding the gear case cover on, or the rockerboxes. Is this correct? Thanks again guys. | ||

Buellisticx1 |

Cam cover oil seal P/N 11124 | ||

Buellistic |

14d: "i" use a TORQUE'ing compound with a coper compound it for better heat transfer for proper torque'ing ... The only places that "i" do not are the ones that require the proper LOCK TIGHT(threadlocker)to be applied ... | ||

Kalali |

Where on the ECMSPY do you folks see the settings for CPS? Which page/screen? I don't see it anywhere.... Thanks. | ||

Phelan |

LaFayette, at Wal-Mart TLE we called that stuff "butter"  ala anti-sieze. One thing I wonder though, is if anti-sieze is considered a lube... I read somewhere that lubed bolts should only be torqued to HALF the torque specs if the specs are for dry bolts because the torque wrench will substantially overtighten a lubed bolt before 'clicking'. I don't know if I explained that very well... ala anti-sieze. One thing I wonder though, is if anti-sieze is considered a lube... I read somewhere that lubed bolts should only be torqued to HALF the torque specs if the specs are for dry bolts because the torque wrench will substantially overtighten a lubed bolt before 'clicking'. I don't know if I explained that very well... | ||

14d |

I haven't been putting antiseize on things unless the FSM calls for it, but I think I'll start as rounded off bolts are a pain in the ass. Kalali: It's under the diagnostics tab, its a big blank white box when you're not connected to the bike. | ||

Buellisticx1 |

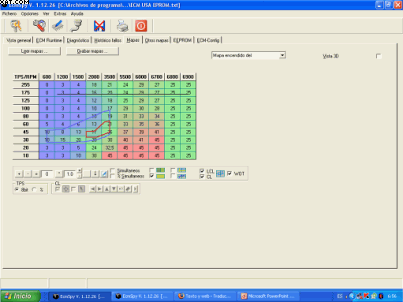

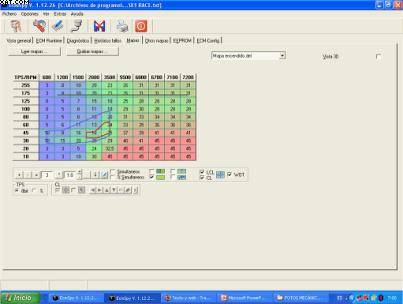

Kalali, Seems to be the post "Reading datalogs - ecmspy and megalog viewer" went out or it was either deleted. Do you mean where are the timing maps on ECMSPY?... if so You can to see them on the same screen than fuel maps are on ECMSPY. The race Ecm has different ignition and fuel mapping than a stock 1.- for X1 USA only (BUEJA120- X1 US VERSION) 2.- FOR X1 INTERNATIONAL ONLY (BUELL KA210- X1 STREET. 3.- BUELL RACE WORLDWIDE (BUELL KA210 X1-RACE) BUEJA120 X1 STOCK USA VERSION (FRONT AND REAR TIMING ARE THE SAME)  X1 RACE (FRONT AND REAR TIMING ARE THE SAME)  Is it your firmware version BUEGC0b0?.. | ||

Drhacknstine |

Setting static timing with CPS is on page 22, right after Running Diagnostics | ||

Kalali |

Thanks guys. I know about the fuel/timing maps but somehow I never saw the CPS box. I'll look for it next time I am in there. | ||

Kalali |

OK. I see. You were talking about the big box where 0 or 5 is displayed...Never looked at the heading where it says CPS Signal. | ||

Orman1649 |

"Replaced it because a RACING part is always better than the stock part ... " This is not necessarily true. A lot of race parts are built to much tighter tolerances and are not designed for long term use, they are designed for machines that get torn apart after a day or two of racing. | ||

Buellistic |

Orman1649: In this case, it is ... | ||

Hugie03flhr |

I did the bronze gear and I also installed the 2007 oil pump that is an upgrade from the older design. As soon as I tap the starter the oil light goes out faster than the old one. So there is an improvement over stock. | ||

Kalali |

My oil light never stays on even for a second after I hit the starter. AFAIK mine is all stock ('00 X1). Maybe you could check the oil pressure and see if it is indeed higher. | ||

Brinnutz |

Hugie, I am also doing the same, but I have yet to finish installing top end, so I won't know anything until I get the motor back and installed. | ||

Hughlysses |

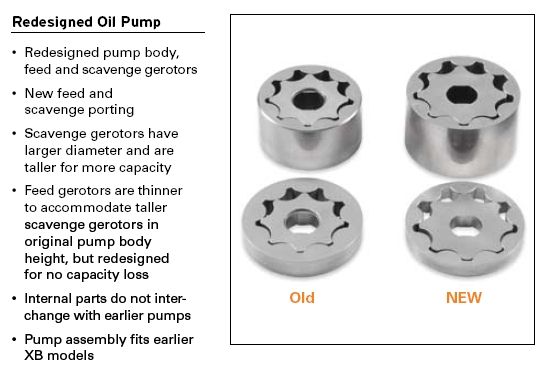

Only difference in 07 pump is supposed to be increased scavenging capacity (see below). Maybe his old pump just had significant wear and the new pump fixed that.  | ||

Buellistic |

With the -02B oil pump the oil pressure is a little higher and it returns the oil from the engine to the oil tank quicker ... The oil pump up-date was done because the XB heads are covered making the engine run hotter ... This is also why the 2008 models have a new XBRR style oil pump ... | ||

Hugie03flhr |

This is all true. That's why I replaced the pump. there was nothing wrong with the old pump but I also like the idea of both pinion and oil pump gears being new so they wear in together.IMHO |