| Author | Message | ||

Johnbranx1 |

Hopefully those that are reading this post will not have need for this. After 8 years of track days I found myself sliding along the ground behind my 1125R at about 80 MPH as it did those flips you see on TV that makes all motorcyclists sick to their stomach. One of the tabs on the frame broke that holds the subframe on and required me to get it welded. My theory on the subframe is that it is built "very" strong to carry two passengers however, this strength makes it too strong for the type of incident I had. Since I only use my bike for track days I am putting on the Buell racing subframe which appears to be made to give first vs. passing the force into the frame. I did a search on the forum and found out what people had done to prepare the bike's frame for welding. 1) Drain the fuel out of the tank....there is a fuel tank drain on the left side of the bike behind the cover for the sprocket. 2. Fill the tank with water. My welder did an awesome job and fixed it for $200. As I said when I started this post, hopefully you will not have a need for this information  | ||

Ccryder |

Thx for the info, although I hope I never need it. | ||

1324 |

I had the same thing happen to me last year at Summit Point on my 2003 XB9S. I lowsided hard somewhere between 50-75 mph setting up for a turn. Details are sketchy, but the bike must have hit pretty hard.  At any rate, I came to the same conclusion last year when this happened. However, I thought that perhaps the welded steel subframe on the XBR and 1125 would have been more ductile and less stiff. Guess that assumption was wrong. I opted out of fixing mine because I didn't have a good local welder with TIG and didn't know much about the parent alloy. I've had some questionable experiences with weld repair of heat treated structures and didn't want to risk it on a pretty critical area of the bike. I even put together a little 'technical report' and sent it to Buell hoping for some sort of correspondance. In my delerium, I sent it to Erik himself which in hindsight was probably an error...should have just sent it to customer service. In my opinion, there are two ways to fix this problem. First, as you said, reduce the lateral stiffness of the structure while maintaining the vertical stiffness. Second, use a lower grade bolt. I don't remember what grade the stock bolts are, but if they can be swapped for a lower grade bolt without adversely affecting the clamp force, the bolt can be made to shear before the frame fails. And I thought I was the only one...glad to hear you are alright and the bike is back to 'normal'. | ||

1324 |

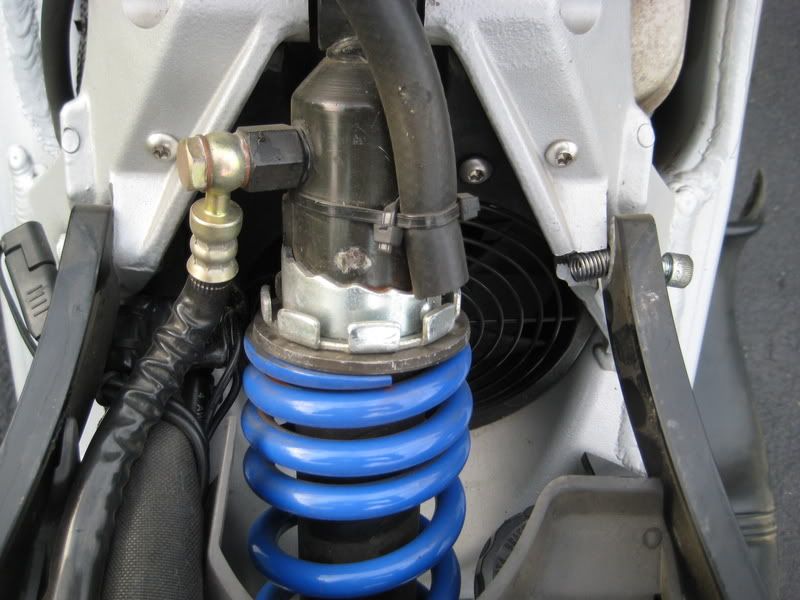

I should also add this picture for clarity:  As you can see, the damage to the subframe isn't very apparent, especially given that the frame boss failed. The bike hit hard enough to tear the frame puck off while denting the frame, bent the swingarm to the point that the axle could not be removed, but the subframe only suffered a few scrapes and scuffs. In all honesty, the subframe was perfectly salvageable and could have been restored with some basic body work and paint. Those ribs were designed for too much strength! I would have gladly rathered to replace the subframe than the frame itself. | ||

Ccryder |

Hmmm, IIRC the 1125r subframe is Aluminum, not steel. Guess I could go pull the seat and pillion seat but it sure looks like ALuminum to me. There are differences b/t models besides looks. | ||

Smoke |

1125r subframe is indeed aluminium. when i bought the salvage 1125r the subframe was broke in a few places and the shock mount tabs were broken off the frame. welded it all back together with some help from coworkers. i have 1 1/2 years of trackdays and races so far on it. tim | ||

1324 |

I stand corrected....which further reinforces concerns on the subframe's stiffness. |