| Author | Message | ||

New12r |

Placed my call to customer service this morning. I am trying to get them to provide just the PART that breaks to us instead of raping us for a whole throttle body. This is like selling you a new motor cuz the valve seat cracks. | ||

Tootal |

I think Hughlysses is right, you could make them .030" or so bigger in diameter and then to get the performance loss back you can mill flats between and on the sides of the screws leaving plenty of meat for the threads yet thinning the extra thickness where it's not needed. This is the way we have our Webers set up on the race car. Here is a crude drawing of what I mean:  | ||

Hughlysses |

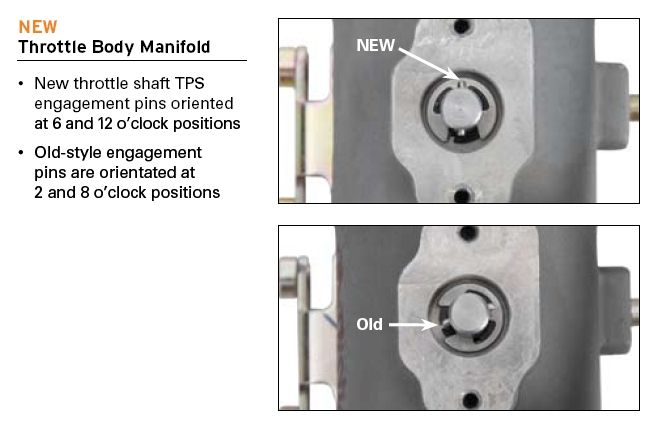

Jim- the thin bead of JB weld might help slighty. Tootal- that's an interesting trick. Seems like it'd be easy enough to do. Interesting- I was looking through the 2007 and 2008 model year technical update booklets (found them on the web way back). The 2007 has new TPS compared to the 2006 and minor changes were made to the throttle shaft as a result. The shaft appears to be the same diameter. Apparently all that changed was the position of the "tangs" in the TPS and the position of a corresponding pin in the end of the throttle shaft. The 2008's changed to having a one-piece throttle body and intake manifold, and added ball bearings to the throttle shaft. It's not clear if the diameter of the shaft was increased or not. | ||

Ft_bstrd |

I think this is a fairly rare occurrance. I can recall less than half a dozen being reported here on BW. I think there are rare occurrances for this kind of breakage. | ||

Rwcfrank |

I modified a few Dodge throttle bodies with great success. The butterfly should go through a "slice" in the throttle shaft and not be bolted on one side IMHO. | ||

Danman2540 |

XB wheels will interchange with Uly's right? | ||

Ft_bstrd |

Yep. Running the R/S wheels on my Uly as we speak. The Uly wheels have 1lb more cast in the rims than stock. | ||

Natexlh1000 |

Delphi makes the fuel management stuff, right? Can you get the shaft from them? I also heard that some FI parts are the same as Ford parts. Can you see any numbers on the shaft at all? Buying the whole thing is absolutely idiotic! | ||

New12r |

Buell customer service has informed me that they are under contract from the T body manufacturer and cannot get the parts separate. As mad as I am I can understand where they are coming from. Still think it's a joke though. | ||

New12r |

I also heard that some FI parts are the same as Ford parts. Can you see any numbers on the shaft at all? There is no Ford product on the market that uses that small of a T body. | ||

Wheelybueller |

The lack of power in MOST Fords I would have thought so. LOL  | ||

New12r |

Well my service writers father is a machinist and I got all the parts ready for him. I told him "I bet you cant machine a slot in the shaft to make it stronger". We should know tomorrow if I can get it made or not. | ||

Rubberdown |

I think U4euh had the same problem. He bought a used throttle body and replaced it. | ||

Tootal |

Well my service writers father is a machinist and I got all the parts ready for him. I told him "I bet you cant machine a slot in the shaft to make it stronger". We should know tomorrow if I can get it made or not. The answer is yes, you can. The shaft is not very large in diameter and the width of the butterfly is large enough that an endmill that size would slot the rod in a few cuts. That's how the Keihen carbs on the Harleys were made. You might try using flat head screws too as they tend to stay tightened better. More friction on the tapers than on the flats of the button heads. He will just have to countersink the holes and find some screws. | ||

Ft_bstrd |

Let's hope you can get something fabbed up. | ||

Ourdee |

From go-kart racing engine setup. If you use slotted button head screws, get a few of them and index them in the holes so that the airflow and slots are parallel. | ||

New12r |

From go-kart racing engine setup. If you use slotted button head screws, get a few of them and index them in the holes so that the airflow and slots are parallel. Talk about taking it to the next step of micro performance! Good idea for sure. | ||

Hughlysses |

I remember reading that Howard Hughes did something similar on his mono-engine cross race plane, the H-1 (now displayed in the Smithsonian). Even though the access screws for all the panels are counter-sunk, he had the screws selected so that the slots in all of them were parallel to the airflow. I'd be willing to be there were WAY more than two of them! http://en.wikipedia.org/wiki/Hughes_H-1_Racer Article on replica someone built recently, including aligning all the slotted screws: http://www.avsim.com/pages/contrails/scartwright/c ontrails_scartwright.html | ||

Etennuly |

With the millions of carburetors and throttle bodies out there can a matching fit-ment not be found? It is a common design shaft. | ||

Hughlysses |

You'd certainly think so, IF you could find some way to cross-reference them. | ||

New12r |

never mind, I was being dumb. (Message edited by new12r on January 21, 2009) | ||

Hughlysses |

Well, the throttle body is 49mm, so I Googled "49mm (carburetor OR "throttle body") and came up with one potential hit. A 1995-1999 Neon with a manual transmission has a 49mm throttle body. That doesn't tell you anything about the shaft diameter, configuration or length but at least it's got the right sized butterfly cutout. I also found reference to at least one Saturn with a 49mm throttle body. Aftermarket replacements are as pricey as the Buell part (no idea if the shaft is available separately), but maybe you could pick one up cheap on ebay or at a junkyard. I found at least one listing for a junk one on ebay. No idea if the shaft could be used. (Message edited by hughlysses on January 21, 2009) | ||

Tootal |

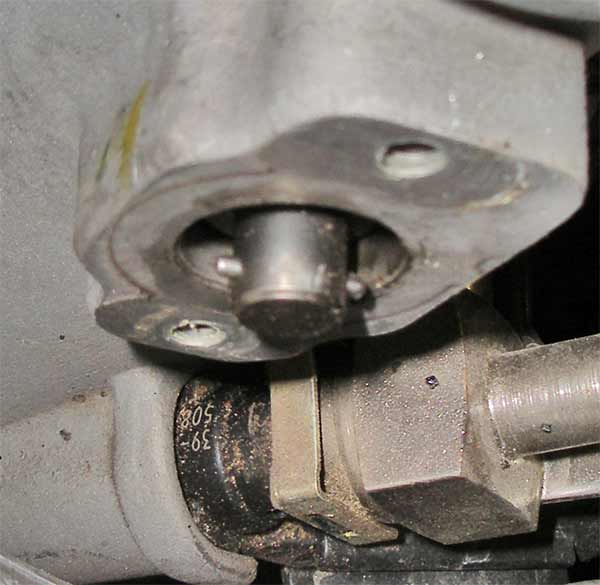

It was mentioned above, something about the TPS connection on the shaft. I had this pic from another thread and you can see it's just a simple pin pressed through the shaft. Easy to duplicate.  | ||

Hughlysses |

Tootal- good pic. The position of that pin (and the corresponding tangs in the actual TPS) is different between the 2006 and 2007 model Buells. Here's a pic from the 2007 model updates PDF:  | ||

New12r |

I am still waiting on the part to get finished up, Just bumping so it does not get archived. | ||

Hughlysses |

Charlie- Looking forward to seeing how this turns out. I wonder if your source or maybe Precision Engineering would be interested in making them on a production basis? A spare throttle shaft might be a really good thing to have on an Alaska trip or similar adventure. | ||

New12r |

I am hoping to get a couple and sell them through GlitchCo. I wont know till later this week. The biggest issue is what kind of stock to make it from. | ||

Ft_bstrd |

THAT is a fantastic idea! Way to "see a need, fill a need". | ||

Hughlysses |

I am hoping to get a couple and sell them through GlitchCo. I wont know till later this week. The biggest issue is what kind of stock to make it from. Cool! Yea, the choice of material is probably the most important question for making a new one. If you maintain stock dimensions, the material will be a big factor in determining if the piece is more resistant to breaking than the stock part. | ||

New12r |

Okey Dokey. here is the part, I only have ONE right now and we are working on trying to get some more made but he has yet to give me a cost. Mine is really a prototype to see if it will work. This one is made of stainless, it took him about 6 hours to get it done and at his labor rate, well.....ouchie! I am hoping to spend some time on it tomorrow to finish up and get it installed, get the tps reset and some ride time in and I will report back.  |