| Author |

Message |

Bomber

| | Posted on Sunday, August 18, 2002 - 02:21 pm: |

|

All . .... after having dutifully double netted all the exhaust stud nuts on my Y2K M2, three out of the four unscrew from the head, rather than let the nuts come off . .. . although this is not a killer, I'd like to know to what torque to tighten the studs, and if I should use something like high temp loctite (which is rated to 475F, or so, which seems a bit low for this application)

as alwayss, thanks for the backup |

Blake

| | Posted on Monday, August 19, 2002 - 12:15 am: |

|

Double netted exhaust suds? heheheh |

Bomber

| | Posted on Monday, August 19, 2002 - 08:51 am: |

|

well, they can't run away if they're double netted, can they?

;-} |

Reepicheep

| | Posted on Monday, August 19, 2002 - 09:26 am: |

|

Bomber... I was the one advocating double nutting the studs (after a very traumatic experience with a sheared stud).

Aaron has pretty much talked me out of it now. A single nut should hold, and if it won't, then a double nut will not solve the problem. Probably the only virtue of the setup is that those second nuts are only on by a few threads (at least on mine), so that when the slightest thing starts going wrong, they fall off and are very easy to inspect.

What worked for my exhaust eating 2kM2 (aren't they all?) was the updated front Y mount, and (as per Aaron's suggestions) letting everything line up naturally and settle in comfortably loose, and gradually tightening all the connectors down with lots of wiggling and patience to let each part find it's happy place.

Bill |

Bomber

| | Posted on Monday, August 19, 2002 - 09:41 am: |

|

Reep . . . . .thanks for the input . . .. I just changed to the Y mount, and allowed every one to make nice while installing the new can . . . . everything lined up nicely, with no stress or prying required to install any of the mounts (the wileyco's rear mounts have a great deal of movement available, which helps) . . . . .

still looking for stud torque data, though ;-}

I'll remove the extra net, er, nut, tonight |

Aaron

| | Posted on Monday, August 19, 2002 - 10:37 am: |

|

I've gone through all this before, but with the rearrangement of the KV, it's not obvious where to find it, so I'll repeat one last time ...

Bill is right, I've found that when the system is properly mounted, the problem with nuts loosening and studs breaking goes away. But I believe it has more to do with mounting stiffness than alignment. Not that I think alignment is unimportant, but I've personally experienced a bike that would destroy any exhaust system in short order no matter how perfectly aligned it was, and once the mounting was stiffened, all the problems disappeared.

Here's my thinking on the subject. Look at how the system is mounted. That connection, between the pipe and the head, is the only place where the exhaust system is solid mounted to the motor, on a '99 or later. Everywhere else is through rubber. So the system is moving around (relative to the engine) everywhere but right there. Could it be that that connection is constantly flexing? Causing the nuts to loosen and the studs to break?

For supporting evidence that this is the case, look at the pre-99's, which sure seem to be much less troublesome. There's a major difference in how the system is mounted, i.e. another place where it's solid attached to the motor, at least in one plane: a little tie-bar between the shock mount and the collector. They eliminated that tie-bar in '99 (it was poorly executed, just butt-welded to the collector, and prone to failure itself), and the problems seem to have gotten much worse.

More supporting evidence ... compare the new "Y" mount to the old mount. Noticeably stiffer. Hmm, could the factory be thinking the same thing?

IMO, double nutting doesn't solve anything, it's just treating the symptom. Personally I'd rather see the nut come loose than have a stud break. I refuse to double nut.

I know a lot of folks disagree, some even argue that letting it swing in the wind is the answer. Force in particular seems to subscribe to this thinking, just look at how they mount their systems. I've seen several fail, too. It seems to me that if you loosen one mount, in this case the front muffler mount, you just make all the other mounts work harder.

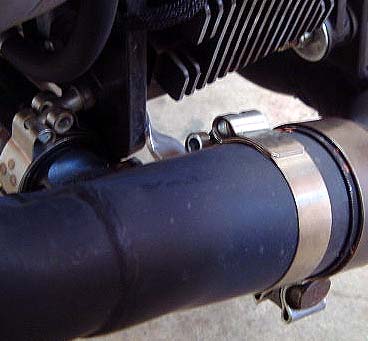

Here's a simple way to attach that tie-bar ...

Clamp part number S1120.G

Tiebar part number 65947-96YA

It's cheap and worth a try. I'd also be sure to use the "Y" mount.

Since I took these pictures, I've made one change. I no longer try to support the tie-bar on the shock mount with that reservoir clamp. I removed the clamp and use a bolt, it's much stronger. I put a different clamp in place to hold the reservoir on. I also now have the Y mount on this bike. It's a good thang.

Stud torque? I don't have the service manual in front of me, but I have no idea how you'd accurately torque something with an interference fit thread. Replace those studs with new ones. As you put them in, I think you'll understand what I'm getting at. |

Bomber

| | Posted on Monday, August 19, 2002 - 10:46 am: |

|

Aaron . . . .thanks for the info . . .you're extra mount looks like the hot tip . . . . looks like something I could gen up on my own, which will get it done quicker (I have a feeling the parts aren't waiting for me at my dealer )

as for the studs, yeah, you're likely right . . . .new ones are the order of the day, I'm sure . . . . . .

thanks, All |

Henrik

| | Posted on Monday, August 19, 2002 - 01:12 pm: |

|

I tried to install a front support tie bar as per Aaron's suggestion. I'm running the Buell Race header on the S2, and while I could clamp the top of the headers, the tie bar is too short, so I'll try to manufacture a longer version.

Don't know if it was the lack of tie bar that was the cause, but on a longer trip just after installing the race headers and old style Supertrapp IDS muffler, I had the race header front mount "shoe" and one of the (fortunately) two muffler straps snap/crack/break on me. Had one header bolt come loose also.

Henrik |

Blake

| | Posted on Monday, August 19, 2002 - 02:16 pm: |

|

Aaron,

On the way home from NYC to Texas last year, my M2 tore the tie bar mount from its stock header (actually an S1W stock header). I had attached the tie bar to the header after purchasing the bike; it was unattached when I bought it.

Thanks for your bright idea with the T-Clamp! It is working very well and allowed me to fasten the header to the tie bar without removing the header wrap I had installed. I simply put the clamp over the wrap. Works great!

One other item of interest... I still use the old style front muffler mount, but I torque the attaching hanger for the Borla muffler so that it is solidly clamped to the mounting bracket. My nuts haven't dropped off yet.  ![:]](http://www.badweatherbikers.com/buell/clipart/proud.gif)

Thanks again for sharing your innovative idea.

As to the "reorganized knowledge vault", whachutalkinboutwillis?  |

Aaron

| | Posted on Monday, August 19, 2002 - 03:50 pm: |

|

"whachutalkinboutwillis?"

The page above this one is no longer a continuous thread, it's now broken up into sub-topics. I thought it'd be a good thing to repost my WhyBuellsEatExhaustSystems theory here where it's at least somewhat properly categorized.

I think they were on the right track with that tie-bar thing, they just didn't do it strong enough. I know I've said this before, but look at how they do it on an FXR/FLH, which is a real similar engine mounting design. Many times more of'em in existence than Buells and yet exhaust system failures are far less common. They have a thick wide clamp all the way around each head tube, attached solidly to the motor/tranny assembly with a 3/8 bolt, versus that tiny little twisted tie-bar attached at each end with a puny 1/4" fastener (and the collector side attachment point is butt-welded onto the collector to boot!). |

Bomber

| | Posted on Monday, August 19, 2002 - 03:59 pm: |

|

Aaron . . .one last question, then I'll get outa yer hair . . ..

Clamp part number S1120.G

Tiebar part number 65947-96YA

those are H-D/Buell part numbers, yes? |

Aaron

| | Posted on Monday, August 19, 2002 - 05:03 pm: |

|

Yes! |

Blake

| | Posted on Monday, August 19, 2002 - 05:26 pm: |

|

Ahhh, then we agree that it wasn't obvious where to find it in the *old* knowledge vault format. It sounded for a second there like you didn't approve of the new subtopic based format. I guess this means I gotta correct the spelling of this thread's title?  |

X1glider

| | Posted on Monday, August 19, 2002 - 05:40 pm: |

|

Torque values for interference fit threads: torque/angle method. Tighten til the nut touches the intended face, then turn the nut a certain number of degrees. The angle depends on the diameter of the stud and to a lesser extent, the thread pitch. The Machinery Handbook might have something in there. I don't have mine with me today, I'm stuck on the King Ranch with TXUtilities, but not allowed to shoot anything while I'm here. (maybe on my way out!)Maybe math geek Blake has that info with him.![:]](http://www.badweatherbikers.com/buell/clipart/proud.gif) |

Blake

| | Posted on Monday, August 19, 2002 - 06:34 pm: |

|

No nut, just a stud. Turn of the nut is a valid structural means to achieve proper preload, actually far more accurate than any torque wrench method, should work on studs too, but a stud bearing down in a tapped hole is too different than a nut stretching a bolt in tension for me to even guess at a good value. If it were me I'd slather the stud with loktite and tighten it good.  |

Ccryder

| | Posted on Monday, August 19, 2002 - 06:47 pm: |

|

The manual suggests 6-8 lb-ft of torque. Ain't much, and you are correct that if you have locking type nuts that this number is not valid. Personally, I use the Nord-lok washers and check my exhaust collar nuts about 1x/ month or about every 3k miles. Nord-Lock. My 00' X-3 just turned 28,000 miles and I have switched at least 4 different exhaust systems on her and after 2-3 tightening down of the nuts, with these washers, they don't move. IMHO most riders get over-zealous with the wrench and smash the gaskets and then they will never stay tight. Like Aaron says put it together with everything in an unstressed state and they won't break or loosen.

Time2Go home.

Neil S. |

Aaron

| | Posted on Monday, August 19, 2002 - 07:13 pm: |

|

No, Blake, no disapproval implied, just rationalizing why I was spewing this drivel all over again.

I'm amazed that anyone could have one of those studs fall out. Every time I've ever replaced one, they've been damn tight going in. Unless the stud is non-original? Something from a hardware store might not be interference fit.

Neil, that's the nut torque, not the stud torque. |

Tripper

| | Posted on Tuesday, August 20, 2002 - 09:00 am: |

|

They switched to a new Conical shaped exhaust gasket recently. Don't use the old flat ones, you'll tighten and tighten trying to get rid of leaks and break the stud. |

Bomber

| | Posted on Tuesday, August 20, 2002 - 09:13 am: |

|

Aaron . . . . .fall out? nah, not so lucky . . . one was a broken stud from an admittedly less-than-glorious job of keeping the old V&H tightly fastened to the rest of the scoot . . . .

the other two are a result of, ehem, some nut behind the ratchet using aircraft locking nuts on the studs . . . . two of the studs happily extracted themselves when said nut behind the ratchet attempted to remove the nuts . . . kive and learn, eh? |

Loki

| | Posted on Tuesday, August 20, 2002 - 04:23 pm: |

|

.040 stainless safety wire is a wonderful pain in the posterior. |

Tripper

| | Posted on Tuesday, August 20, 2002 - 07:29 pm: |

|

Loki: don't safety wire the seat. |

Xwoody1

| | Posted on Monday, August 26, 2002 - 10:19 pm: |

|

WHILE ON A ROAD TRIP ONE OF MY REAR EXHAUST STUDS

BROKE. SHAME ON ME I KNOW.I CHECKED THEM BEFORE I

LEFT HOME,THEY WERE TIGHT.TOO TIGHT, MY DEALER/

MECH. HAS THE WRONG INFO. HE TIGHTENS "THE HELL

OUT OF THEM". GOT FIXXED UP IN A SMALL TOWN FOR

$30.00& A BEER. GREAT GUY, BROWNS CYCLE SHOP IN

WALSENBURG,CO. DO YOU GUYS THINK I SHOULD REPLACE

THE OTHER 3 BECAUSE OF THE POSSIBLE STRESS?I DID

RIDE ABOUT TEN MILES OR SO LIMPING INTO TOWN.IF SO

WHATS THE BEST WAY TO GET THEM OUT?I'VE READ MOST

OF THE PAST POSTS AND UNDERSTAND THE IMPORTANCE

OF TAKEING TIME, WIGGLEING THE EXHAUST, AND TIGHTEN THINGS SLOWLY.THIS SITE IS AWESOME AND THANKS FOR ALL THE INFO.

SCOTT |

Blake

| | Posted on Tuesday, August 27, 2002 - 01:23 am: |

|

Xwoody1,

For thirty clams and a beer you got a real bargain. If the other studs are not broken or cracked, you should be able to forcibly unscrew them by double nutting the ends and wrenching the stud out. |

Xwoody1

| | Posted on Thursday, August 29, 2002 - 10:49 pm: |

|

YEAH THAT WAS SMOKIN DEAL.IT WAS

THE START OF A TRIP TO NEW MEXICO,

HE SAVED MY ARSE.DO YOU EVEN

THINK I SHOULD REPLACE THE OTHER

STUDS.I'VE BEEN TOLD THAT THEY

SHOULD BE GOOD.

SCOTT |

Skulley

| | Posted on Friday, November 29, 2002 - 10:58 pm: |

|

If your having trouble with your nutz, try this.

http://store.bobscycle.com/browse.cfm/4,10595.html

Blake,

How about a permanent list of fixes at the top of the page, like you do with part #'s, so we don't keep posting this stuff.

Nord-locks http://www.mcmaster.com/

serrated hex nuts http://www.mcmaster.com/

safety wire kit http://store.bobscycle.com/ |

Littledog1

| | Posted on Saturday, November 30, 2002 - 09:21 pm: |

|

Kelby and Neil,

Thanks for turning me on to the nord-locks and the mcmaster web site. I have all kinds of things that I need to use them on.

Thanks again,

Mickey |

Knickers

| | Posted on Tuesday, April 22, 2003 - 04:21 pm: |

|

A couple of observations after installing a race header this weekend on the S3:

1. Nuts were really loose on the stock header (5500 miles).

2. 6-8 ft-lbf on the new ones loosened up very quickly after a few minutes of running.

3. Exhaust gaskets are quite compliant.

Might I be doing more harm than good by continually retorqueing the nuts? After all if the factory is installing them at 6-8 ft-lbf and never retorquing them why should I. Since the gaskets are compliant, continual tightening could be smashing the gasket until they bottom out, perhaps obstructing the port or putting the header into solid contact with the head. More vibration and fatigue? I'm assuming the loose nuts came about by further compression of the gasket not the nuts backing off, probably should check that out.

BTW I couldn't get the screamin eagle gaskets that come with the kit to seal on the front cylinder so I reverted to the stock tapered gaskets.

Thoughts?

Kurt |

Teenc

| | Posted on Thursday, November 11, 2004 - 11:14 pm: |

|

When my exhaust gaskets wore out I replaced them myself. I think I may have torqued the nuts on too tight because just the other day the rear ones were loose. When I went to tighten them, I realized that one of the studs had broken off, half still in the engine case. Am I going to have to drill that out and re-tap and use a helicoil? I am just wondering what the best way to repair this is. How do you install a new stud? Double nut it and screw it in with a wrench? Any info on the actual repair process would be greatly appreciated. |

Al_lighton

| | Posted on Friday, November 12, 2004 - 08:56 am: |

|

Andrew,

your best bet is this: Jims Drill Guide |

Aaron

| | Posted on Friday, November 12, 2004 - 08:58 am: |

|

You didn't overtighten it. They break because the exhaust system moves around too much, independent of the engine, which flexes those studs until eventually they break.

You generally have to drill it out and heli-coil it. Highly unlikely that you'll remove it with an easy out or other extractor, as the threads in there are an interference fit. You're more likely to break the extractor than remove the stud, and then you have a real mess. Some people claim success welding a nut onto the broken off stud and then turning it out, but I've never been successful at that myself. Difficult to weld and get penetration down inside a hole like that, it wants to fill before it gets hot enough.

Also highly unlikely that you can drill it out without the little fixture tool that JIMS makes. Once the drill bit wanders a little and finds the aluminum (and it will), it'll never go back onto the steel. The tool works slick as hell. It uses a quarter inch drill bit, and often it cuts so straight that you end up hollowing out the 5/16" stud without even touching the aluminum. I've even been able to, on occassion, remove the hollow stud and save the threads in the head, not even needing to heli-coil it.

Once you get it fixed, mount your exhaust system better, using the late model "Y" mount and/or the little collector mount tab as used on '96-'98 models. It's been my experience that when the system is mounted better, the nuts will stay tight sans any locking device and the studs will last. It's why I refuse to use a locking device on the nuts, it's treating the symptom instead of the problem. Good luck. |

|

Exhaust Stud Torque/Securing »

Archive through November 12, 2004

Exhaust Stud Torque/Securing »

Archive through November 12, 2004

Exhaust Stud Torque/Securing »

Archive through November 12, 2004

Exhaust Stud Torque/Securing »

Archive through November 12, 2004