| Author | Message | ||

Nik |

They've done it with Big Twins: http://www.skyray.us/ , why not an XL? There's a class of light homebuilts that use an engine called a half VW, because...well its half a type I (bug) vw engine. Having to cut a crank, cams and head in half opens a pandoras box in my mind. They advertise 38-37hp at 3.5k rpms from ~1000ccs. Here's one manufactures example: http://www.greatplainsas.com/schalfvw.html So why not hack the primary and transmission off an evo and bolt a prop to the end of it (bearing issues aside?) With aluminum cylinders it should end up being lighter. Choose cams and porting to emphasize the extreme low end (getting revs <3k or just above would be ideal.) Care would have to be taken when mounting to isolate vibration but the 1/2 vdubs are pretty bad (they can't be balanced completely, the vibration can only be balanced to a specific rpm so you end up with transient rpms you need to avoid.) | ||

M1combat |

Why such low RPM? If it's really a requirement then the big twin would be a much better choice. | ||

Oldog |

keep the primary and gear box cases and build a PSR unit. the reason for low rpm Hi torque is prop tip speed which needs to be subsonic When you hear a high performance piston prop take off at max power and the "pronounced propellor noise" thats the tips getting close to super sonic (not that good) the length, balance and materials all have an effect as well, as props can fail from excessive forces | ||

Mr_grumpy |

Would it not be easier to use a smaller, lighter, higher revving engine & gear it to the prop? | ||

Jackbequick |

For an airplane, the wider the torque curve the better it is as the propeller load is constant and continuous. If you get to a given power level with two large cylinders instead of four small ones, and the mass of the engine is less, then the weight advantage goes to the V-twin. The propeller drive on that gives a reduction in the gearing, the propeller is running at less then the crankshaft RPM. The ratios available are 1.52, 1.62, 1.68 and soon a 1.92 to 1. So it looks like the more power you can get at the lower RPM the better it is for the application. In the time I've spent around airports there was always evidence of a eternal quest for cheap and more widely available engines (V-8's, Corvair and VW flat fours, etc.) for use in aircraft. And nearly all of them used some type of reduction drive to lower the prop speed. I like the idea of riding your V-twin to the airport to get in your V-twin powered aircraft and break the fragile bond with earth. Nothing like making a departure from a high risk motorcycle ride to a nice safe environment like flying enhance the enjoyment. Not much threat up there. Except for gravity. And human error of course. Jack | ||

Xl1200r |

Would it not be easier to use a smaller, lighter, higher revving engine & gear it to the prop? Some guys are using subaru 4 cyl engines and doing exactly that. As Oldog said, props can't go supersonic (though I've heard some large diameter ones that have and it's LOUD). Because of this, most props are built for a 2800 rpm application. This is also why direct-drive engines like Lycomings are rated and redlined at 2800 rpm. That's why you only get 150-200hp out of a 300+ cid engine. | ||

Spatten1 |

I'm no expert, but I think ideally you want flat, radial engines, or another configuration that cancels primary and secondary vibration well for aircraft. 1) With the parts that fall off, and screws that back out, and oil lines that wear through on my Buells from vibration, I'd probably not want that in my airplane. 2) Also, durability will be higher with a better balanced engine. | ||

Jimidan |

Why not... -20 lb. flywheel -vibrates like a MoFo -45 degree is OK if it is a radial, but not for a twin -revs too high to make power -see Spatten1 comments. PS_ I still love one in my S2 and S1 though. I took the S2 out for a 260 ride yesterday. | ||

Nik |

In the time I've spent around airports there was always evidence of a eternal quest for cheap and more widely available engines (V-8's, Corvair and VW flat fours, etc.) for use in aircraft. And nearly all of them used some type of reduction drive to lower the prop speed. VW's and corvairs are nearly always direct drive. The XL isn't ideal no, but my thoughts are that it would be better than hacking a VW in half, and dealing with all the problems that causes. | ||

Nevrenuf |

years and years ago, according to my brother inlaw who does have one of those kit planes and likes everything about flying, said that someone tried to use a harley motor and barely got it down the runway. i'd have to ask him again for the details but it's one of those things he's always mentioning because of my love for motorcycling and his love of flying. of course, right now, he's out in vegas getting remarried by elvis. | ||

Jramsey |

I think the question would be if HD built an airplane would you fly in it.  | ||

Spatten1 |

Love that T-shirt slogan! Another favorite is: "British bikes may leak oil, but Harleys leak parts" | ||

Sweatmark |

BMW Boxer option: http://www.ultralightnews.com/engineinfo/bmwconver sion.htm | ||

Spatten1 |

BMW engine makes sense, flat twin has low vibration once up to up operating RPM. | ||

Nik |

Too heavy, to much power. I just want ~35hp in an ~80 pound package. No psru, no starter or electrical system other than what's needed to spark. | ||

Mr_grumpy |

Briggs & Stratton not make anything suitable then?  | ||

Xl1200r |

I think you're going to have a hard time finding much that makes that kind of power with that little weight at that low of an RPM. | ||

Thumper74 |

Honda makes some small engines... They now make small jets, so the reliability is there... | ||

Birdy |

Small motor geared down is what I have seen on these puddle jumpers at the local airport. I'd think a 1203 would shake one of these tiny airframes apart in no time. I thought a Cub was small but these thing remind me of a kite with a lawn chair bolted on. | ||

Rotchcrocket51 |

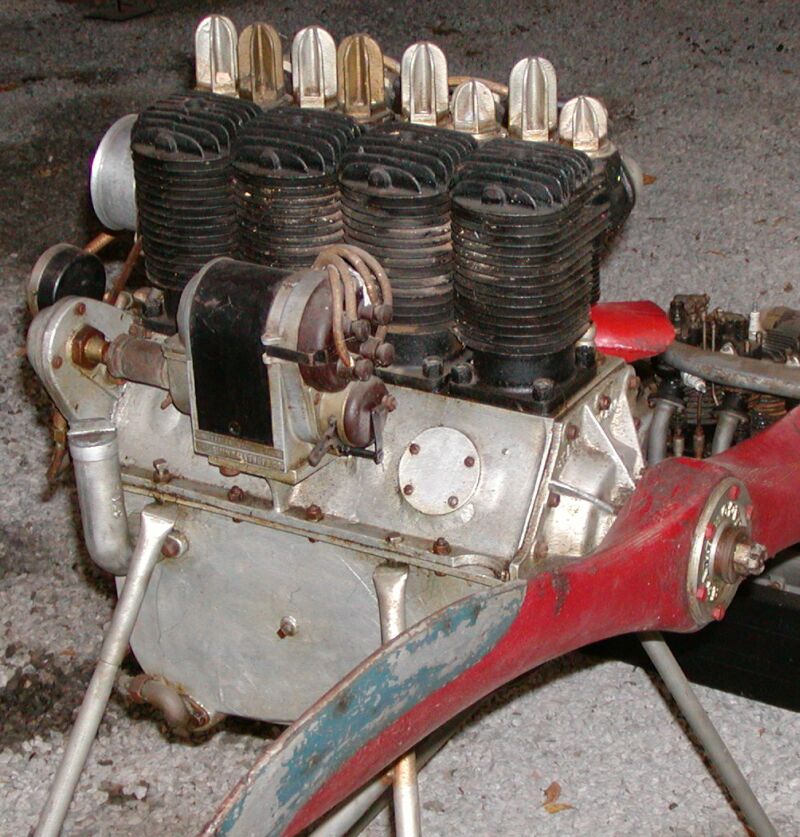

A Harley engine in an airplane is OLD news! This one is in the Wheels Through Time Museum in Maggie Valley, N.C.   | ||

Rotchcrocket51 |

| ||

Slaughter |

Heath worked in the 1920's with Henderson I-4 engines in light aircraft kits. Keep in mind, back in these days, people were willing to accept engines that needed minor overhauls every 20-50 hours and major rebuilds every 100-200 hours. Few folks know that the original "Heath Kit" was an aircraft: The Heath parasol http://www.hendersonkj.com/airplanes/heath/index.h tml The Heath/Henderson was powered by the Henderson MC engine modified for the use:  Original use:  | ||

Jimidan |

Put a Rotax in it. I hear that they make pretty good engines. They have non-certified engines that can be used in "experimental" aircraft, and also have certified engines. | ||

Nik |

I don't want a reduction driven two stroke. I want an air cooled, hand propped, low compression, medium displacement engine. I'll probably just go with a regular full VW with aluminum cylinders. Rotax uses ducati ignition coils; my two stroke Vespas use ducati ignition coils. Care to guess that part that fails the most often on them? They're also very thirsty. | ||

Norcal_blast |

Rotax uses ducati ignition coils; my two stroke Vespas use ducati ignition coils. Ducati doesn't make ignition coils, they source an off-the-shelf item from an outside vendor just like everyone else. I just swapped one out recently, it was Showa Denso part stamped "made in Korea" | ||

Nik |

Ducati doesn't make ignition coils, they source an off-the-shelf item from an outside vendor just like everyone else. I just swapped one out recently, it was Showa Denso part stamped "made in Korea" Mine are stamped "ducati - made in italy" except in italian. They make coils. Maybe they don't for their own bikes anymore because they realize they're crap, but they make coils and other electrical system parts. |