| Author | Message | ||

Ezblast |

Looking forward to the after pictures! (as well - very nicely done so far!) EZ | ||

Berkshire |

after some work:     | ||

Berkshire |

This will be a temporary setup - with stock springs, rev limit will have to remain stock. Crappy 2-piece valves are probably not safe to use w/ stronger springs and/or higher revs, and they're too small for top-end power anyway. I'll run the stock stuff until additional funding accumulates, then upgrade to the 7mm stuff and higher compression... until then, I don't expect much power. XB springs & retainers are cheap: 18245-02 - XB valve spring - $3.95 18258-02 - XB spring retainer - $0.93 18260-02 - XB valve keeper - $0.75 XB valve guides are same O.D. & length as Blast, so they should fit right in the Blast head. Heads will have to be cut for larger seats, as XB valves are larger than Blast. 18020-83 XB intake valve seat - $6.50 18011-86 XB exhaust valve seat - $6.50 18690-02 - XB intake valve - $17.75 18691-02 - XB exhaust valve - $35.75 16461-02 - XB valve guides (4-pack) - $9.95 18094-02 - XB valve stem seal, appears to include hardened spring seat Most likely I'll use aftermarket 7mm valves, guides, seals and seats, and of course I'll have to re-do the port work for the larger valves. | ||

Ezblast |

Did you use a machine or a steady hand;0) - have you done any head work before? What tools are you using - lathe, mill, or press involved? - EZ | ||

Berkshire |

The worst thing about the OEM setup - and probably hardest to fix - is the alignment between the intake "manifold" and the intake port floor (top side in this pic):  Grinding the top side of the manifold flange and pushing it "up" while tightening the bolts helped the alignment along the top of the port - doing that plus slight port enlargement on the sides gave good matchup everywhere except the port floor. The problem there is that both the manifold and the port are angled downward where they bolt together, so there is sort of a dip in the floor. The only way to fix it that I can think of is to weld up the bottom of both the port and the manifold to fill in the dip - or just fill the bottom of the port, raise the top, and custom make a new intake manifold. Can it be called a manifold if it only has 1 inlet and 1 outlet? I think not, but what else would it be called?  | ||

Berkshire |

Used a dremel w/ flex-shaft & 1/4" carbide burr (cylinder w/ round head), then 1/2" & 1/4" sanding drums, then sanding by hand w/ little pieces of various sand paper - wetordry works best. I have ported OEM iron Ford heads (larger grinder & carbide burrs required!) and done some touch-up work on aluminum SBF heads. My Blast heads could use more work, but that will wait until the larger seats are installed. | ||

Ezblast |

Very nice! EZ | ||

Gearheaderiko |

Great job on the info, pics and write up! Just a few points of info for those also considering this: XB uses 'beehive' valve springs and the Blast uses traditional valve springs.(while I didnt check)Retainers and certainly keepers are different and you cannot use Blast valves with XB springs (not that you were going to) without sacrificing valve float rpm. I'm very doubtful that an XB 'beehive' valve spring is $3.95 when aftermarket 'beehives' command 2-5 times more money than traditional valve springs. I've been using high pressure valve springs (comparable retainers and keepers) on my unmodified stock valved Blast head and running it up to 7500 rpm with the B50 cams. While I cant vouch for continued longevity, they certainly wont fail immediately! Stock valves can flow enough to produce usable power to 7500 rpm. While power peaks at 6800 rpm (B50's, probably XB's), you've got the power band for another 700 rpm, enough to get you quickly through the turns without shifting. You (likely )wont reach redline in 5th, but you'll get there quickly in 4th (7500rpm=90mph appx). Once again,Berki, thanks for advancing the cause with pics and mods that some others would keep to themselves. Thats what makes Badweb great! | ||

Swampy |

Yes great info and pictures! In the VERY old days I used to use DEVCON to fill intake port floors and raise intake ceilings for a more direct flow into the combustion chamber. It is a JB Weld like product. | ||

Berkshire |

LOL - used JB Weld on the Ford intake - now THAT'S a "manifold"! ...figured it wouldn't hold up on Blast though. The mounting tab for the link bar is really what keeps the intake port from being moved higher, but I think maybe the tab could be thinned down a bit if someone wanted to go "stage 3". I was also surprised by the price on the springs, retainers & keepers - PN's came out of an '03 XB book, parts guy typed the numbers in the 'puter, and it printed out the list with prices and correct descriptions (except 18094-02 and 40290-04 prices). I should probably go buy spring setup before prices get "updated"! Valves, guides, seats are similar price as aftermarket, but aftermarket stuff looks better. XB & Blast use same rockers & shafts, but lifters have been updated (18538-99B, $29.95) - not planning to swap over (or go aftermarket for similar price), but curious about what they changed to make it a "B". | ||

Buuueller |

AAAHHHHhhhhh...Im so pissed. HD has had my bike two weeks now. I returned the polished head to them last Sat. They call today and say the valve parts they said was there...isnt. Six to ten day wait. So F*CK it.   I guess I dont get high rev's this year, cuz I cant wait any more. I guess I dont get high rev's this year, cuz I cant wait any more. | ||

Ezblast |

Patience - I would wait - trust me when I say it is worth it! EZ | ||

Buuueller |

Well, you were right. I should have waited. I got the bike back rode it twice then the rain fairy decided to camp out. Now Im on call for a week and have to drive my service truck home. So I didnt do myself any favors. Anyhoo, my high tech seat of the pants dyno says that the polish job added a little mid to upper rpm power. Feels like a steady pull that increases from mid to rev limit due to the improved flow. Could have lost some grunt down low. But then again it could be the same as before, just giving the impression of lost torque, since the mid power is up a bit. I didnt do quite as good as Berkshire because the valve seats were already installed and I didnt want to damage them. I gave the seats a slight radius towards the port, but care should be taken because you dont want to take too much off or they could come loose. I also didnt get around to port matching the intake to the head. But I got a good polish on what I was able to reach. If your planning on doing this, notice in Berkshires picture of his combustion chamber that he cleaned it up but didnt "polish" it. Thats a little hot rodding trick. If it is left with a texture like that it helps keep the air/fuel mixture suspended, for a more effective burn. Everything else should be smooth as glass. Im sure proper tuning would tell more, but I cant afford to dyno tune just yet. (Message edited by buuueller on March 31, 2008) | ||

Gearheaderiko |

XB head to Blast frame tiebar bracket. Angle iron cut, drilled and bent. Crude, but one of those "lets see how long this lasts" deals. 6000 miles, 7500rpm, 2+? years of racing and it doesnt show any signs of fatigue or bending.    | ||

Berkshire |

Ah! A picture is worth 1000 words - thanks, Erik! If I'm understanding this correctly, the "thunderstorm" heads are NOT the same as XB heads, right? If that's correct, my next question is what the differences are - I'm thinking XB heads were first w/ 7mm valve stems, followed by '04 sporty heads, but wondering if t-storm heads or '04-up 1200XL or ANY Buell or H-D heads have the "bathtub" chambers with large quench areas, or are the XB heads my only option for getting quench chambers? The cam swap and port cleanup has apparently made some difference, as I've had to back off my ignition timing! I'm thinking some squish area would allow more advance. I've bumped the limit up to 6700 and the bike runs 99 and wants more - I have to back off the gas to stay out of the rev limiter. No perceptible valve float, but I'm still not planning to go higher until I switch to 7mm stuff. | ||

Gearheaderiko |

Correct. XB heads are not Thunderstorm heads. XB heads are '04 XL heads (dont know about any later years). I believe XB heads are the only HD/Buell heads to have the 'bathtub' chambers. | ||

Fast1075 |

Very nice blend work there Berkshire...WELL DONE!...glad to see you didn't hack away at the floor of the port...too many heads are ruined by killing the floor radius. I generally mask the seats and glass bead the intake ports to help prevent low rpm fuel puddling...but thats just my own personal slant... | ||

Berkshire |

thanks, Fast! My philosophy is that the air/fuel charge should be coming DOWN toward the valve seat on the short side, not hitting sideways, so all I did there was smooth out the curve. They definately need more work around the guides, and of course a total enlargement would be needed if/when I go for larger valves. But after getting some installation prices on larger seats, I'm putting those plans on hold and revving up for "Operation: XB". That'll be better anyway - less down time! Interesting note: I'm helping a friend work on his '94 Chevy S10 pickup - timing chain broke at 210K miles, dropped pieces in the oil pan, and exhaust valves are all bent. It's a 2.2L 4-banger pushrod motor, pre-vortech type - probably the cheapest motor GM made in '94! AND... The valve springs are beehive type! Valve stems are skinny - didn't measure, but may be 7mm. Nice lightweight tapered pushrods too! I'll take some measurements after pulling the head. | ||

Berkshire |

They were 7mm stems, slid right into the XB guides, and only slightly too small at the seats - makes sense since, it has 550cc per cylinder. Stems are noticably longer though. Springs look tapered, not beehive. | ||

Rhpaw |

Dunno if this is the wrong section- but this is definitely the 'been there, done that' area. I have to take off the head. Do I have to do a full drop on the motor to get the head off, of will a partial drop be sufficient? (leaving the rear mount untouched?) thx! | ||

Gearheaderiko |

Partial drop only. There are some pictures around the Thumper forum. Gotta go. Inside Pass tomorrow, leaving now! | ||

Reuel |

I stick a jack under my engine, unbolt the mounting bolts from the head, lower it a bit, then disassemble everything from the head so I can get to it. Oh--don't forget to take the muffler off. It'll be in the way. Gotta go. Need to refill my rum and Dr. Thunder! ... | ||

Fast1075 |

There is now available a billet front mount to replace the breakage prone "do not remove" bracket...there are two styles available....one fits the stock blast head..the other fits XB and late XL heads. Only available from NRHS as far as I know, and it is a nice piece. | ||

Ezblast |

I haven't heard of the bracket breaking - bolts yes, but the bracket? I do know that tubers had that problem though. EZ | ||

Krjoseph |

My bracket broke in October, but one bolt had broken first. I still don't know when that bolt broke and how long I rode it in that condition. The stress of only one bolt caused the mount to brake. But I think the stock mount will be fine if you're using the new updated bolts. And yes, I now eyeball all mount points as part of my pre-ride. But that NHRS mount looks pretty cool. (Message edited by krjoseph on February 03, 2009) | ||

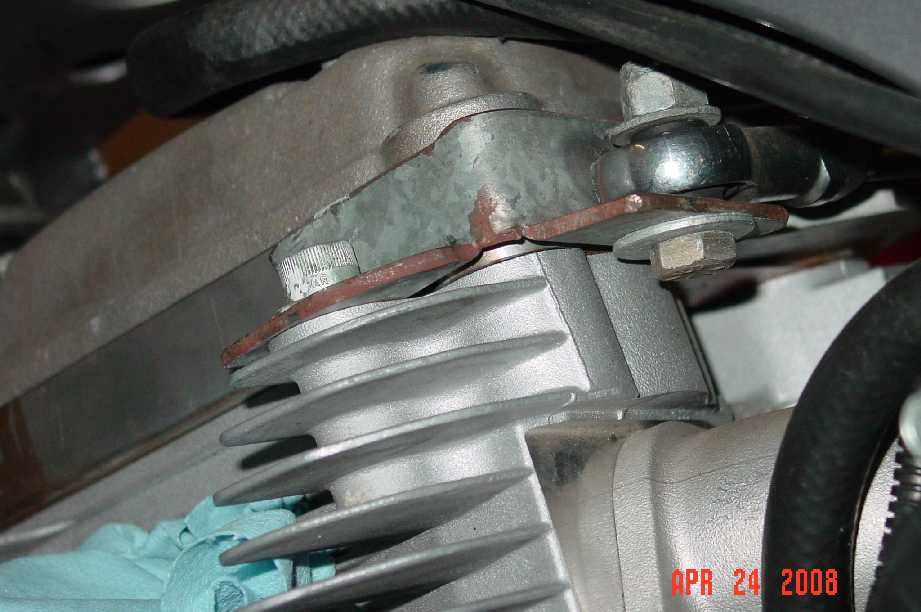

Buuueller |

Um yeah...they break.  | ||

Krjoseph |

Yep. Mine broke in EXACTLY the same place. Did the other bolt shear off too? I could never get the bolt out and and just bought a new head. | ||

Ezblast |

Wow scary stuff. EZ | ||

Krjoseph |

Yep, it was a bit hairy. I was in traffic going to work. Crossing a railroad track, felt a thud then my bike started shaking like a jackhammer. Luckily, I was about a mile from work. I nursed her gently to the office about 10 mph. It was so embarrassing, 50cc scooters were passing me. | ||

Ezblast |

At least she didn't leave you stranded! EZ |