| Author |

Message |

Josh

| | Posted on Monday, May 13, 2002 - 11:48 pm: |

|

Rick, your torque curve is nice and right in the midrange. Best way to get the HP curve to continue on it's journey would be Thunderstorm heads. Get complete Stage1 from Sport Twin for $850 (since they won't take those lightnings on trade).

I'd also lose the S&S aircleaner in favor of the race unit, but you might dyno it on/off first to see the difference.

Josh |

Aaron

| | Posted on Tuesday, May 14, 2002 - 12:25 pm: |

|

Rick: that curve is about right for the 91hp Lightning motor. The mods you describe don't really address the top end, and you've got a strong mid-range from the Supertrapp.

The torque curve tells the story, the cylinder fill is falling off as the rpm rises. Things are happening faster and faster and the flow isn't keeping up.

Like Josh says, the heads are likely constraining it, but I'd also add that the exhaust system plays a huge role. Clearly that exhaust system is timing it's draw to hit the chamber on overlap at about 4200rpm. The Lightning cams have enough overlap to make the exhaust system effective, too. |

Hoser

| | Posted on Tuesday, May 14, 2002 - 09:53 pm: |

|

Fella's:

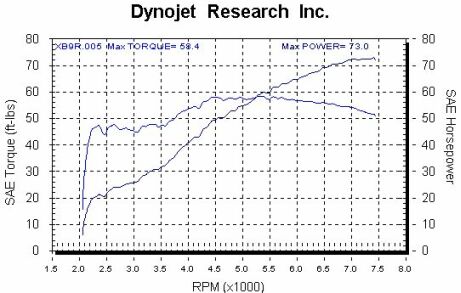

For your viewing enjoyment , a genuine XB9R dyno graph , performed today on a demo w/ 2200 km. on the odometer , which showed up on the doorstep.

Hoser |

Rick_A

| | Posted on Tuesday, May 14, 2002 - 10:26 pm: |

|

Well, eventually I was gonna have the heads ported...but I figured if I'd go that far I may as well go for a 1250 kit...so it'll be a (long)while. In the meantime I'll see what several more disks on the 'Trapp will do for me. I guess I forgot that these kind of bolt on mods tend to mainly only address the "EPA dip".

Better than the 'bolt at least...now if my S1 could lose 30lbs and shrink a few inches I'd be all set! |

Jmartz

| | Posted on Wednesday, May 15, 2002 - 09:11 am: |

|

Hi Hoser, nice to see you back on the board. XB #'s not all that impressive.

jose |

Aaron

| | Posted on Wednesday, May 15, 2002 - 09:25 am: |

|

Yeah, but notice how it hasn't really started nosing over yet at 7500rpm. They're getting some breathing out of it. |

Mikej

| | Posted on Wednesday, May 15, 2002 - 09:51 am: |

|

Almost like that engine is saying it has room to grow. |

Jmartz

| | Posted on Wednesday, May 15, 2002 - 10:19 am: |

|

With the 3.125 stroke and the skinny stem vakves with tapered springs and small collars, it would seem that the engine is easily capable of reaching 8,000 rpm. I read in a magazine (cycle world, I think) that a peppier model is in the works. I would still prefer 4 x 3.5 but as of yet I can't even build it myself for lack of available parts. |

Aaron

| | Posted on Wednesday, May 15, 2002 - 10:38 am: |

|

Yeah, but controlling valve float isn't the real challenge, getting enough breathing to make that rpm worthwhile is the challenge. I did a ton of work to get the Blast to make power at 7500rpm. Here the XB is doing it right out of the box. I suspect these new XB heads are an improvement.

4x3.5 is a proven combination fer sure. Only about a zillion Chevy's running around with it. |

Blake

| | Posted on Wednesday, May 15, 2002 - 10:52 am: |

|

Jeff wins the T-Shirt!  Thanks for posting the dyno chart! Thanks for posting the dyno chart!

My impressions... I'm wondering if that XB9R might need some dialing in. Have you verified cam sensor timing and TPS? From a purported 92BHP engine I was expecting to see closer to 80RWHP. I got 83RWHP out of a jetted stock '00 M2 (similar BHP rating), and 74 RWHP out of a '97 M2 with jetting, S1W header, Borla Muffler and race intake. A race ECM will hopefully bump up the low/mid range torque. Torque curve does have a nice shape though.

Let the XB9R dyno wars begin.

Aaron, you REALLY need to get one.  |

Aaron

| | Posted on Wednesday, May 15, 2002 - 11:01 am: |

|

No I don't.

I betcha that low rpm flatness is reversion.

This muffler will be a little more challenging for the aftermarket, what with the holes through it. |

Jmartz

| | Posted on Wednesday, May 15, 2002 - 11:22 am: |

|

I don't know what think of the heads on the XB. I agree that they have been reworked as it pertains to the current models but they are still the same casting with the ports in the same location. A new straighter path intake runner would have been the ticket.

You are right about the Chevy's. |

Gcpoland

| | Posted on Wednesday, May 15, 2002 - 11:39 am: |

|

Rule of thumb for a Harley drive train is RWHp =80% of crankshaft HP. 92x80%=73.6 I would guess this machine to be right on tuning wise. Having seen the pre-production head, I am going to say there is a lot of untapped potential there unlike the Revolution motor. I think this motor has a lot of serious unused potential. But then again I have been wrong before.

Gary |

Hoser

| | Posted on Wednesday, May 15, 2002 - 02:38 pm: |

|

Blake:

The graph shown is "as delivered" , no "tweaking" took place.I'm hoping forthe release of a race kit but I have no knowledge of the existance of such a kit.T shirt ??? , I was not aware of a prize offering !!. Our track day was cancelled due to wet / cold conditions today , was so looking forward to track time on the XB., it's been re booked for the 19th of june. today , was so looking forward to track time on the XB., it's been re booked for the 19th of june.

Gotta go , I'm at work and musn't get busted for goofing off.

Hi to y'all , and ride safe!!

Jeff |

Mikej

| | Posted on Wednesday, May 15, 2002 - 02:48 pm: |

|

This ain't goofing off, for you it's called research. |

Blake

| | Posted on Wednesday, May 15, 2002 - 04:13 pm: |

|

So at 101 BHP a Buell X1 is eating up 20 HP in the primary, tranny and final drive? I don't think so. I don't know where that "rule of thumb" got started, but I don't buy it. Proof is that my stock '00 M2 made 83 SAE RWHP when it's only supposed to have 91 BHP at the crank.

Motorcyclist's 101 BHP '99 S3 dynoed at 90.1 RWHP.

I'd say 10% is a better rule of thumb.

I'd say that XB9R needs some tuning and/or some better gasoline. I still want to ride one before passing any type of judgement!  |

Axtell

| | Posted on Wednesday, May 15, 2002 - 05:14 pm: |

|

Blake-when you get a chance call me @ work 515 243 2518 ,Ron |

Gcpoland

| | Posted on Thursday, May 16, 2002 - 12:34 am: |

|

Blake

I completely disagree. Using actual crankshaft numbers, then seeing what you get in the chassis, 80% is average, 85 is above average, and 90% is never seen unless you blueprint the transmission and driveline. In my experience 80 is average. I have seen 10 hp differance at the crank on 2 identical production motors. Your reading published advertising numbers and trying to match them to real world numbers. I still stand by the 80% number.

Gary |

Ryan23

| | Posted on Thursday, May 16, 2002 - 02:45 am: |

|

Take a look at the header on a firebolt where it goes into the head. You can see where the pipe gets smaller. I didn't measure it but it dosen't look like 1 3/4". The collector looks like 2". I think they are going to surprise us with the race kit. |

Aaron

| | Posted on Thursday, May 16, 2002 - 09:26 am: |

|

From what I've seen, bone stock 101hp carb'ed motors tend to run mid-80's, plus or minus a few. The FI version seems to run a tad less.

The 91hp Cyclone motor tends to run mid-70's. It's the exceptional one that breaks 80. |

Blake

| | Posted on Thursday, May 16, 2002 - 02:18 pm: |

|

I have to admit, I'm ashamed to have used the word "proof" in my statement above. It's anecdotal evidence at best. I still have a hard time believing that we are losing 20% to driveline inefficiencies. On an inertial dyno I wouldn't be surprised, absent correction factors (Aaron says there are none), to learn that we are losing as much as 10% to driveline inertia. Exclusive of frictional losses, spinning up the crankshaft/flywheel, primary, tranny and rear wheel while revving the engine from 2000 to 7000 rpm in 6 seconds has to require a SIGNIFICANT amount of power.

All power lost to drivetrain inefficiencies is transformed into heat. Yeah, your tranny can get pretty darn hot. But how much heat does 20 HP produce? The conversion factor is 745.70 W/HP, so we have 20 HP * 745.7 W/HP = 14,914 W or nearly 15KW or 50,889 BTU/HR for those familiar with HVAC. This is exclusive of the heat of combustion and the engine's friction losses.

Here's a mental experiment to wrinkle your brow...

If you removed your engine's pistons and connecting rods, and replaced the crank with a straight smooth shaft (no lobes, journals, flywheel), how much power input to the shaft would be required to spin it up to 7000 rpm with the tranny in 4th gear and the rear wheel spinning freely given the following time limits:

1. Ten minutes (600 seconds).

2. Six seconds.

What if anything do our answers imply concerning our debate on drivetrain inefficiencies?

Is drivetrain efficiency dependent on load level and/or speed?

Should I be out riding right now instead of trolling the board?  |

Aaron

| | Posted on Thursday, May 16, 2002 - 03:38 pm: |

|

"Aaron says there are none"

I said that?

Actually, it was claimed here before (by someone else) that in fact, the Dynojet software does apply an inertia correction to try to make the numbers more comparable to a brake type dyno. He attributed the somewhat higher numbers as you go to higher gears to this effect, saying essentially the higher gear ratio you have, the more mechanical advantage the drum has on the crank and therefore the lesser the effects of flywheel inertia, causing the Dynojet's correction to be that much farther off. If I understood his post correctly.

I didn't argue the point, and I suspect it may very well be true. |

Blake

| | Posted on Thursday, May 16, 2002 - 05:15 pm: |

|

I mispoke, I was recalling that you had said something along the line that there is no bike specific correction factor that the software applies. A general correction factor could exist. It wouldn't make ANY sense though. It would invalidate the "rear wheel" part of RWHP.

Without ANY factor at all, you would still see the same variation in results versus lower and higher gear runs. The higher the gear, the closer to a brake dyno result you would get. |

Caboose

| | Posted on Thursday, May 23, 2002 - 05:45 pm: |

|

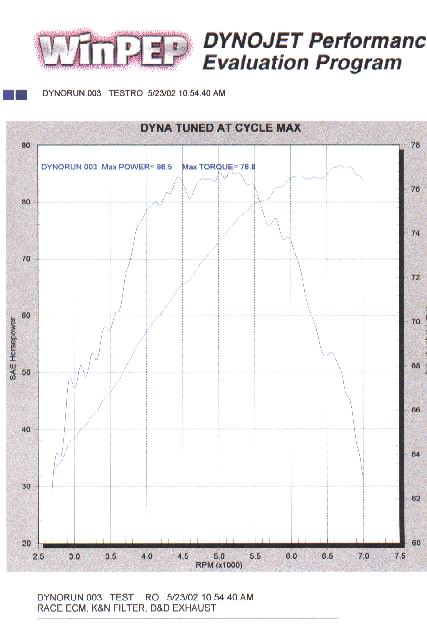

Just got back from the dyno-shop. As promised here's my runs. 2001 Buell X1 / full D&D exhaust system / K&N filter with gutted airbox.

86.5 horsepower ******* 76.8 ft/lbs torque |

Aaron

| | Posted on Monday, May 27, 2002 - 04:33 pm: |

|

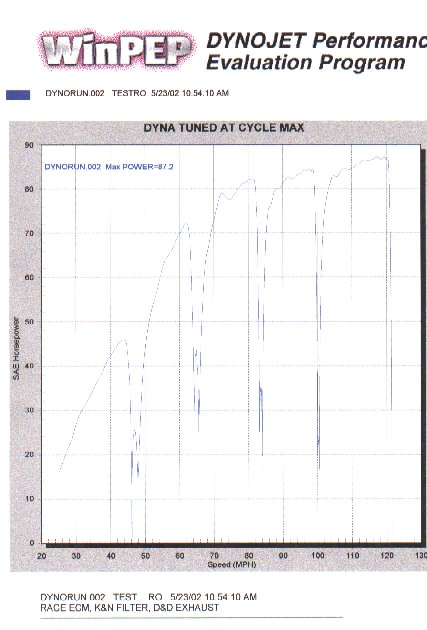

Owner: Matt (didn't catch the last name) - Buell tech at Sun HD/Buell in Thornton, CO

Mods:

Nallin Racing stage 2 head work.

Nallin 1250 kit

Red Shift 585 cams

Mikuni HSR42

Nallin (Force?) exhaust system

Screaming Eagle Selectable curve ignition module (Dyna 2000) - Curve 1

The tach pickup messed up on this pull, but I was taking it right into it's 7500 rpm rev limiter! Looks like it could make even more power with a higher limit.

Also, we had a 165 main in it, a huge jet for up here, and it was still showing slightly lean. But it was the biggest jet we had.

Ray Richard's 2003 XB9R

Mods: none

Note the leanness in the mid range ... needs a race ECM!

Also note that it has not yet nosed over as it gets into the rev limiter. |

Aaron

| | Posted on Monday, May 27, 2002 - 04:50 pm: |

|

Here's Matt's full chart ... I guess the tach pickup only screwed up for a small range ...

|

Aaron

| | Posted on Tuesday, May 28, 2002 - 06:51 pm: |

|

Aw c'mon, guys, I can't be the only one who's impressed by that dyno sheet! That's 111 horsepower, ferchrissakes. We haven't seen that much since Smadd posted his sheet! Rocket, isn't that sheet worthy of at least one "bollocks!"?

If it's any consolation, Rocket, this bike only pulled 96hp on it's first pull. Tuning matters. Bring that carbon fiber boat anchor over here! |

Sarodude

| | Posted on Tuesday, May 28, 2002 - 07:07 pm: |

|

Uh, now that you mention it, it is pretty impressive... cough, cough

The A/F graph looks odd in the beginning. Is that just latency in the system induced by some sort of hose / tube length?

-Saro |

Aaron

| | Posted on Tuesday, May 28, 2002 - 07:16 pm: |

|

I sure wish I knew. Sometimes I see that, bad like this one, sometimes I don't see it at all, or very little.

During the pull, the software puts a bar graph of the a/f across the bottom of the screen, and it's behavior is the same, whack the throttle open and it goes full lean for a few seconds, then settles down.

What confuses me is that it doesn't *always* do it, haven't figured out yet what I'm doing differently. There must be someone out there who knows??? Hoser? Pammy? This a/f monitor thingie is still a little new to me. Sure saves a lot of time, though. |

|

»

Buell Dynamometer/Dyno Testing Archives »

Archive through May 28, 2002

»

Buell Dynamometer/Dyno Testing Archives »

Archive through May 28, 2002

»

Buell Dynamometer/Dyno Testing Archives »

Archive through May 28, 2002

»

Buell Dynamometer/Dyno Testing Archives »

Archive through May 28, 2002