| Author | Message | ||

Toastwithjam |

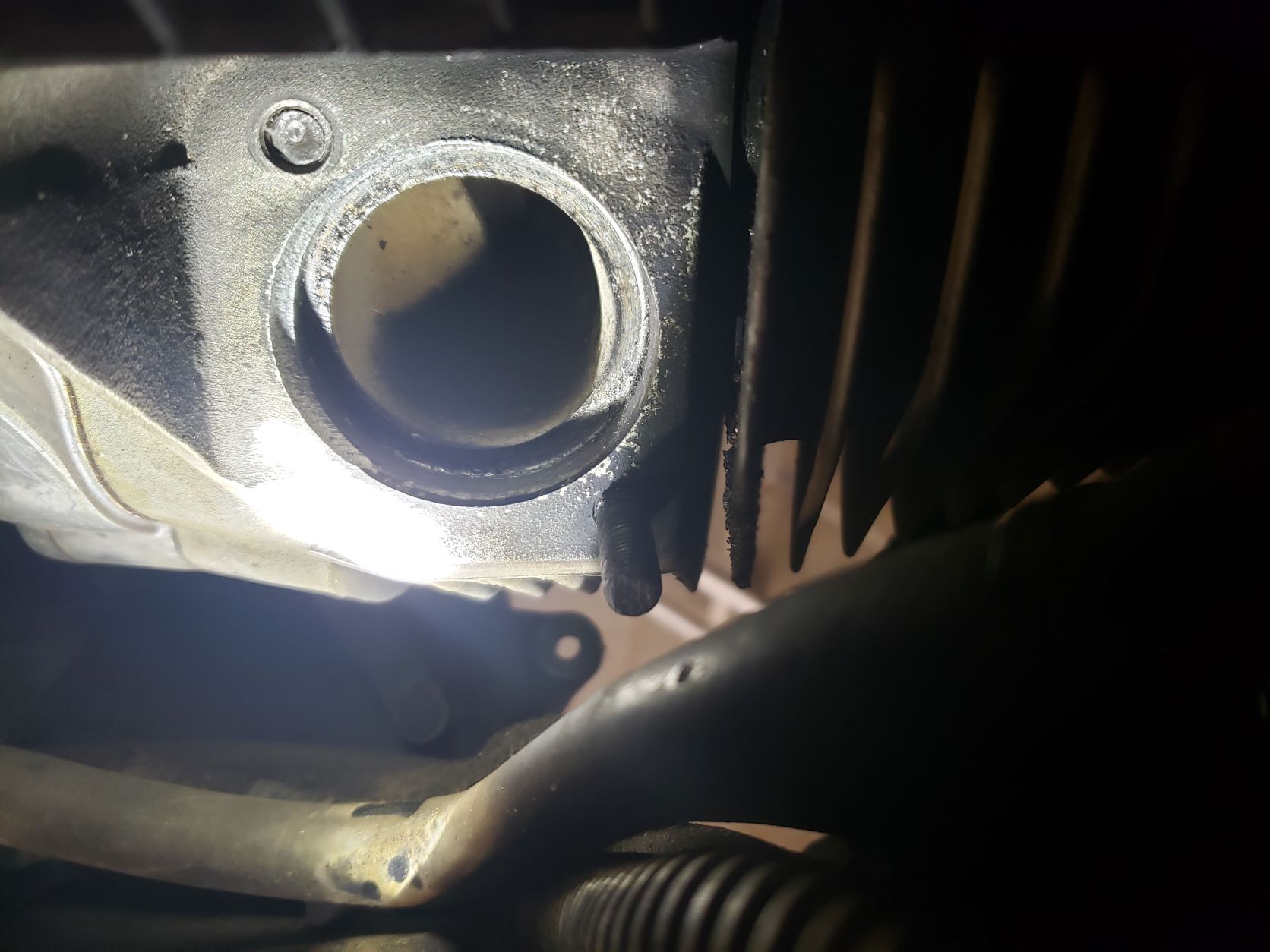

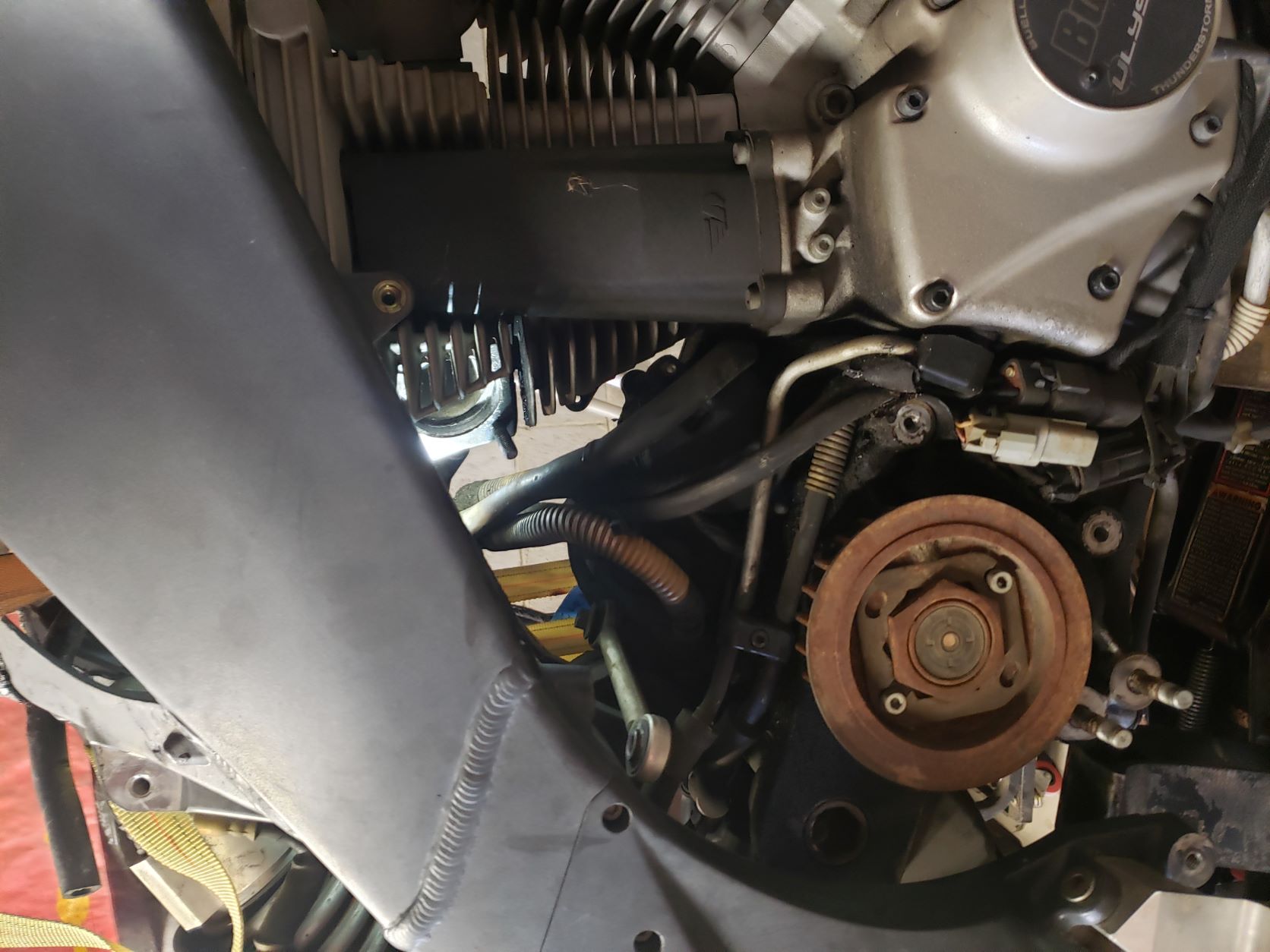

Ive got a broken exhaust stud on my 06 xb12x. I was wondering if you all have any tips for getting it out. Im trying to use a Jims 1705 drill guide. Right now my biggest problem is that I do not have enough room to work. The broken stud is on the rear head so the fuel rail gets in the way. Is there any way to rotate the engine further down? Also has anyone used the Jims 1705 before? Should I drill a little hole and then try and use an easy out or just drill the stud out? I am somewhat worried that I will ruin the threads. I have attached some pictures to clarify the problem.    | ||

Zane |

the best answer would be to weld a piece onto the stud and they spin it out. If you don't have access to welding equipment I'd say drill it and try an easy out. Either way it's not going to be a fun job. | ||

Toastwithjam |

I don't have welding equipment. I could get some if it is that much of a better option. Would it be possible to weld in there with that little room? | ||

Zane |

It would absolutely be a tough job. It might be better to farm the job out. Maybe try an easy out first then. Drilling a hole deep enough to allow an easy out to grip enough will be a beast of a job. Not sure about clearance though. You most likely will have to pull the engine out no matter what you choose. Does anyone have a better solution???? | ||

Cupcake_mike |

I'd pull the engine, not much more work than you've already done rotating it... | ||

Toastwithjam |

Okay, thanks guys. I'll start working on pulling the engine. I would love to farm the job out but I don't have the money for that. | ||

Hughlysses |

The way a lot of guys do it is to weld a nut over the stud. If you can roll the bike as-is, you could take it to someone with a MIG welder and get them to try it. The technique has a good chance of success because the welding heats up the stud red-hot, which can break the corrosion that has it seized in the head. It may take a few tries; if it doesnít work the nut will generally break off at the face of the stud, so you donít lose anything and you can try again. It can be a very quick process- 5 minutes to weld on the nut and screw out the stud, so it might cost very little. Search YouTube; there are plenty of videos showing the technique. Worst case, give up, pull the rear head and take it to a machinist and get the rear stud drilled out and re-tapped. | ||

Ratbuell |

I've drilled a hole INTO the broken stud before; hit the stud with a torch for a while; then used an easy-out in the stud, to spin it out. Easier with the engine out, of course (mine was a tuber, I simply removed the head from the engine - it needed base gaskets anyway). | ||

Cvc |

Stop by my shop and I will pull it out I have a mig a tig and a stick welder should not take a half hour. | ||

Figorvonbuellingham |

If you have access to a pneumatic engraving tool you can put a punch mark about an 1/8Ē away from the outer radius then put the carbide tip of the engraver in the punch mark at about a 40 degree angle and push counter clockwise. Works pretty good. Be careful not to slip out of your punch mark and into the threaded area or you will make it much more difficult to remove. Helps to squirt a little Kroil on the threads and a heat gun would help also. | ||

Mnrider |

I've gotten dozens of broken studs out in my 43 years if being an auto tech.I would use the jig and a new left handed drill bit,sometimes they come right out with the drilling.Then heat it up some and use a twist easy out. Good Luck! | ||

Toastwithjam |

Tried welding it. Got the nut to attach but it broke off when I tried to turn it. | ||

Toastwithjam |

Thanks Cvc, where are you located and what would you charge? | ||

Toastwithjam |

An update for anyone else trying to fix the same problem in the future. I ended up pulling the engine, it wasnít very difficult but it took longer than expected since it was my first time removing a buell engine. Now that I had enough room, I drilled out the stud using a guide. That went well and now just the threads from the broken stud remain. Iím currently trying to figure out the best way to remove the remaining threads. I am considering an easy out, picks or a punch. If anyone has advice for how to proceed Iíd be happy to hear it. | ||

Littlebuggles |

Soak with a penetrating oil, carefully back it out with a (quality, not the cheap stuff) easy-out or the like. Be careful, it really sucks when those break off! | ||

Rdkingryder |

This looks promising. https://youtu.be/-8N0y0jVAng |