| Author |

Message |

Snacktoast

| | Posted on Thursday, April 07, 2016 - 09:24 am: |

|

D_Adams, don't feed the troll.

This is what he does, constantly. |

D_adams

| | Posted on Thursday, April 07, 2016 - 09:50 am: |

|

Well aware of it. What did I do with that popcorn emoticon? |

Buelliedan

| | Posted on Thursday, April 07, 2016 - 02:16 pm: |

|

I do cylinder heads for a living and I can tell you that the heads in the 1190s are VERY well designed and the ones they used for WSBK were definately at their optimum!!

I would love to know what you think they could have designed better into the heads Steve? |

Stevel

| | Posted on Friday, April 08, 2016 - 04:11 am: |

|

Dan,

The statement that the engine is at its design best and that "this best case" was represented in the WSK effort is just wrong. If it was so good, it would have been much more competitive. Yes, as I stated the base design is good, but unlike the Ducati, has never undergone improvements since its initial design. The mods applied were only band aids. The basic faults are poor flame propagation and an unstable cylinder bore. The inlet ports are too large. The inlet ports lack a venturi so there is no air acceleration to the back of the valve. There is insufficient space for more valve lift. In order to do this, the cams must be lifted by at least 4mm. This would allow more space for the valve springs, valve guides and correct finger geometry. These simple changes require a casting change. You can be the best head guy around and not be able to fix these faults without adding metal and space.

The cylinder is way too thin at 106mm bore and because of this moves around under load. The bore is only supported at the bottom and on one side at the chain case side on the top because of the open deck design. This problem is further aggravated because the engine is an integral member of the chassis and it undergoes significant stress during operation. The solution is again a new cylinder casting, adding more bore material and closing the deck. Of course, a new casting would require a fistful of new components as well. I am certain that I am not the only person to discover these problems. It is not rocket science, but these changes would be expensive and as we now know, funds for this were not available both then and now. These simple but expensive changes would make a huge difference in power output, engine efficiency and reliability. |

Stevel

| | Posted on Friday, April 08, 2016 - 04:39 am: |

|

D adams,

You are correct, I don't race, but I do build motors and have been doing this for more than fifty years. This motor is not my first rodeo. I have already spent a great deal of money and time on this motor. You should know that no one makes aftermarket parts for this motor. All the parts that I want to use I have had to design and make myself and I've made many to date. This has been an ongoing effort on my part that has been very painful and I hope rewarding in the end. I see no one else anywhere, including the factory making the effort that I am. |

Buelliedan

| | Posted on Friday, April 08, 2016 - 11:32 am: |

|

Steve,

I have no argument with what you said about the cylinder design. You are spot on there and yes the heads could do a better job with port velocity as you said.

But I think they did an awesome job with the parts they were given. IMO these engines were never designed to make 200 hp and for them to get close to that number with the WSBK engines i think says a lot for the folks involved in that effort.

I just don't think they realized how difficult and expensive it was going to be to field a competative team to race with those boys.

But I sure admire their grit for trying!!! |

Ljm

| | Posted on Friday, April 08, 2016 - 12:36 pm: |

|

I for one would like to see SteveL's innovations, although given that he has a huge amount of time and proprietary interest, I wouldn't blame him if he doesn't. |

Vagelis46

| | Posted on Friday, April 08, 2016 - 03:10 pm: |

|

Just to point out that when EBR raced in WSBK the noise limit was 107dB....... This year the noise limit is 115dB... This year the Duc Panigalle has lost their silencers and they manage to keep with the Kawasakis down the straights for the first time after many years...... A great improvement for the 2cyl bikes at last !

I wonder if the EBR could be more competitive with the 115 dB limit...... |

Hughlysses

| | Posted on Friday, April 08, 2016 - 03:21 pm: |

|

I wonder if the EBR could be more competitive with the 115 dB limit......

I'll bet they would. They would definitely have been more competitive in their first year. That bastardized side mount exhaust apparently required the rear suspension adjustments to be significantly compromised to prevent the exhaust from grounding out in right turns!

(Message edited by Hughlysses on April 08, 2016) |

Buelliedan

| | Posted on Friday, April 08, 2016 - 03:52 pm: |

|

Pretty moot at this point as I don't see anyone coming along with 10-20 million dollars to field a WSBK team for EBR. |

Stevel

| | Posted on Saturday, April 09, 2016 - 06:28 am: |

|

Dan,

My point is not that the WSB effort wasn't as good as the team could do, given the circumstances, it was, but to assume that their effort was the best the engine could do is just wrong. The engine requires the casting changes I mentioned to be competitive with the WSB field. It isn't just the lazy ports either. Close examination of the horsepower increases achieved across the whole ICE field reveals that they were due to greater valve flow under the most desired part of intake event. This includes greater valve lift and higher valve acceleration rates on the both the opening and closing cam ramps. These changes have been made possible because of all the new high strength materials available today that were not available in years past. That said, the Rotax engine cannot take advantage of these newest materials because of the lack of room within the cylinder head. This space limitation exists primarily under the cams. To facilitate the increase in valve travel, the cam base circle must be raised a minimum of 4mm, more would be good. At the same time, the valve spring must also be longer, as its stroke must also follow the increased valve lift. These dimensional changes would slightly upset the finger follower geometry where the finger pivot would also have to be raised slightly to center its arc of travel. The finger itself would also require longer wipe pads, as they are too short at the moment for the required stroke increase. Even after those changes, the cam chain would need to lengthened by a couple of links to handle the head height change.

Those changes are very expensive and that is the primary reason they were not done. What can be done with the existing head is reduce the base circle of the cam somewhat, drop the spring seat floor a bit, reduce the height of the valve spring pad a bit, go to taller ovate wire valve springs with a larger diameter (there is space to do that) and shorten the valve guide top hat. Some, but not all of those things were done by the WSB team. Now I have now acquired ovate wire valve springs that fit the bill. It took me two years to find them. Yes, I could of made them custom, but that was beyond my hobby budget. So, I had to find springs that already exist for some other engine. The ovate wire was a necessity, as it provides more space between the coils. Of course the spring change requires new spring retainers, which I had to make. Longer valves are easy to source, but I found a company in Japan that will make me custom hollow head valves out of Nimonic80a high nickel steel, which I will go with. The weight of these is almost as light as titanium, but with infinity more strength and durability. That firm is Toa Arai. At the moment, I am stuck trying to get camshaft masters made for my cam design. I have been promised these from Andrews, but I have been waiting more than a year, unfortunately, it appears my job is at the end of their priority list. I cannot start the machine work needed on the heads until I can trial install the new cams. I spoke to Web Cams, they will grind the cams, but they need masters from Andrews.

I could go on writing about my trials and tribulations, but I'll just say every part I have made has been painful and expensive. I can say that the crank, rods and pistons are done and acquired as well. |

Stevel

| | Posted on Saturday, April 09, 2016 - 07:02 am: |

|

Ljm, Thanks for your thoughts. I don't do this for profit. I don't have a company that sells anything and I will publicly post everything I do, both good and bad. I have no proprietary interest here. I do this as a personal challenge.

Vagalist46, In my experience, noise is wasted energy that could be better used pushing the pistons. I doubt very seriously if the noise level increase will add any power. Increased scavenging can have detrimental effects as well as benefits. It does no good to piss raw fuel and fresh air into the exhaust system during cam overlap. All exhaust systems must have properly timed back pressure at the exhaust port to limit wasted fuel/air charge and in my experience, it is usually much less noisy when you get it right. |

Reepicheep

| | Posted on Saturday, April 09, 2016 - 11:20 am: |

|

I want Steve's "hobby budget".  |

Mustang0

| | Posted on Saturday, April 09, 2016 - 02:10 pm: |

|

Very interesting read Stevel.

I would have thought in this day and age cam masters would be obsolete. couldn't the master be drawn on Solid works or something similar and then transferred over to the grinding program. I'm guessing the Nimonic steel valves are more costly than Titainium. I good luck in your build. |

Stevel

| | Posted on Saturday, April 09, 2016 - 03:32 pm: |

|

MustangO, Astute observation! Yes, Andrews is just one example. their masters are a simple data file, but they use super high dollar grinders. Because of that, machine time is expensive. Those high dollar machines are dedicated to production cams with runs in the hundreds. Folks that make one off cams inevitable use the older manual machines. Hence, the requirement for masters. The other advantage to the old fashioned masters is that I could use the masters on one of my manual milling machines to make blanks.

On the cost of Nimonic steel valves. I don't know yet, but the cost is always driven by the short machine run where the material cost is almost irrelevant in relation to the set up costs having to be absorbed by the small number of parts. Often 10 cost the same as one. When I made my pistons, the minimum run lengths were typically 100 to 1000 each for most providers. In the end, I went with Pistal in Italy. Their minimum run was 4, but they cost me more than $3,000. |

D_adams

| | Posted on Saturday, April 09, 2016 - 09:30 pm: |

|

quote:noise is wasted energy that could be better used pushing the pistons.

If you say so.

I've only managed to hit just shy of 180 hp at the wheel on mine. Stock motor, 8 lb exhaust and tuning done with IDSPD and myself. If I'm not mistaken, EBR's efforts made more than 200 hp at the wheel, but they were still 30-40 hp short of what the I-4's were making. The budget disparity was simply too great to overcome though. Even with Hero throwing money at the problem (although I don't think they did enough) it wasn't in the same league as what the rest were doing every weekend. EBR might have spent $150-200k on a weekend, the other teams were blowing through $500k+ at the same time. It's all a matter of scale and economics I guess. Small company of 100, of which 2/3 were on other projects for said benefactor, 15 guys building motorcycles and then a very small group actually supporting the race efforts versus what everyone else had. I cheered for them regardless of the outcome, but they were essentially taking a slightly hopped up production motorcycle and pitting it against machines that cost 10x more and had oodles of R&D behind them. David & Goliath type scenario. |

Bud

| | Posted on Sunday, April 10, 2016 - 04:48 am: |

|

interesting read the WSB rule book, there is more to it than making just a few very power full race engines |

Vagelis46

| | Posted on Sunday, April 10, 2016 - 12:21 pm: |

|

If we are talking about the WSBK efford, EBR's biggest problem was reliability....the engine seized in every single race during the first rounds and the top rider fell and got injured ..I think that the engines were pushed too far by the team in order to be competitive.... so it seems that the 200hp is too much for this engine....... 180hp seems all right.... which is fantastic for a 2cyl engine |

Hughlysses

| | Posted on Sunday, April 10, 2016 - 01:37 pm: |

|

^ That was true in the first season but they seemed to have solved their reliability issues in the second season and were making further performance progress until Hero pulled the plug. |

Vagelis46

| | Posted on Sunday, April 10, 2016 - 05:58 pm: |

|

I am afraid that was not the case , not even the 2nd year ........ |

Sprintst

| | Posted on Sunday, April 10, 2016 - 07:05 pm: |

|

Investor Stars?

Bradd Pitt

Tom Cruise

norman reedus

keanu reeves

Frankly, I don't care if EBR races or not. Race bikes aren't what we buy.......

(Message edited by sprintst on April 10, 2016) |

Davegess

| | Posted on Sunday, April 10, 2016 - 08:01 pm: |

|

The engine would have been reliable IF the race team had let EBR build them the way we knew how to. They got all wound up about how much they knew about v twins and WBSK and how we didn't and proceeded to do things they were specifically told not to do.

Look at the engines the Splilath team have used, very reliable an the TT is not exactly easy on engines. |

Court

| | Posted on Monday, April 11, 2016 - 08:24 am: |

|

The Race Team was an odd and unusual animal.

My sense is that it had nearly nothing, with the exception of borrowing the name and bikes, to actually do with EBR . .the company.

HERO did the WSBK effort as a completely separate initiative from their involvement with EBR. I'm not sure, and could be completely wrong, that EBR had anything more to do with it than we did . . . being outside observers.

The mission, and it worked well, was simply to splash the HERO name about in the world market.

I don't think anyone in East Troy had much more control or involvement in the "racing" than anyone here on Badweb did. Erik Buell would not have run it that way or made the same mistakes week after week.

Again . . that is a TOTAL GUESS. |

Steve_a

| | Posted on Monday, April 11, 2016 - 05:10 pm: |

|

Control of the WSBK team in the first season was . . . difficult. People thought they knew more about the bikes than people with long experience with them. The issues were most clearly seen at Laguna Seca when Pegram was faster than the official team bikes.

The budgets for both years were tiny. They would have supported a decent American Superbike effort. It was Hero, not Erik or EBR, who pushed hard to go WSBK in 2014. Erik assumed they were acting in good faith, would deliver on their other promises, and acquiesced. That decision had a lot of negative consequences, in perhaps the grandest understatement ever. |

Davegess

| | Posted on Monday, April 11, 2016 - 07:00 pm: |

|

hat decision had a lot of negative consequences, in perhaps the grandest understatement ever.

How true! |

Davegess

| | Posted on Monday, April 11, 2016 - 10:01 pm: |

|

Steve, did Hero ever launch the 250 the team was working so hard on? Has it actually reach production? |

Willmrx

| | Posted on Tuesday, April 12, 2016 - 11:29 am: |

|

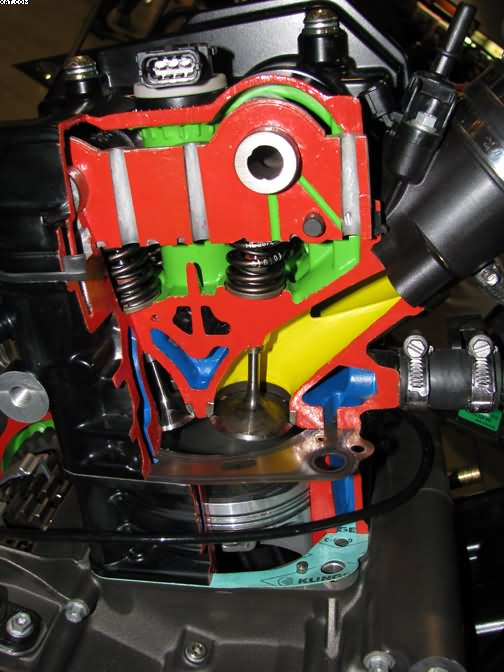

Here is a photo of part of the head.

|

Hughlysses

| | Posted on Tuesday, April 12, 2016 - 02:22 pm: |

|

^ Dave- the last article I saw in the Indian moto-press said they expect it will be released during the "festive season", whenever that is. Emphasis on "expected".

Edit- Apparently that means mid-May:

http://m.carandbike.com/hero-bikes/hx250r

(Message edited by Hughlysses on April 12, 2016) |

|