| Author |

Message |

Dtaylor

| | Posted on Wednesday, September 11, 2013 - 11:45 am: |

|

Hey Matt,

It appears that the seal part number is 12074.

Re: Pulley -- did you check out American Sport Bike? There's also a couple of 65 tooth pulleys in good shape on eBay at the moment.

If you are in a real pickle, PM me. I could lend you the pulley off of my spare rear wheel, but I expect you could get a new one from American Sport Bike nearly as quickly. If you do ship from the States to Canada, be sure to go regular post, as the couriers will nail you with their brokerage fees.

cheers,

Doug |

Teeps

| | Posted on Wednesday, September 11, 2013 - 12:33 pm: |

|

Froggy Posted on Tuesday, September 10, 2013

It can be done without removing the wheel without modifying the tensioner or even removing it, you just loosen the axle and it will give you enough slack.

I just installed a new belt on my bike and there is no way it could have been installed without removing the idler wheel.

I even counted the teeth (135T) on the belt twice to make sure it was correct.

When I finally got the belt and idler on it tight beyond belief.

I called Al @ American Sport Bike for reassurance that it was ok.

He confirmed the obvious, that the belts are VERY tight.

Mattmcc00,

That rear pulley is dead; I think you have found the problem. |

Mattmcc00

| | Posted on Wednesday, September 11, 2013 - 12:53 pm: |

|

now the question is did the pulley kill the belt or did the belt kill the pulley?

Or is it something else entirely killing both? |

Mattmcc00

| | Posted on Wednesday, September 11, 2013 - 01:07 pm: |

|

got both sprokets, and the seal at americain sports bike

for 323+shipping to canada |

Hughlysses

| | Posted on Wednesday, September 11, 2013 - 02:30 pm: |

|

Wow, that rear sprocket is seriously chewed up. IIRC, the shop manual says if the paint is even chipped off the teeth, you're supposed to replace it! (I have ignored that recommendation so far.)

Any idea if it looked like that before you installed the new belt? I can well imagine that sprocket would EAT a new belt. |

Natexlh1000

| | Posted on Wednesday, September 11, 2013 - 02:36 pm: |

|

I have never seen a pulley look like that!

All hooked up like it was running a rusty dirtbike chain instead of a smooth rubber belt.

Suppose abrasive grit did that? |

Teeps

| | Posted on Wednesday, September 11, 2013 - 02:57 pm: |

|

Mattmcc00 Posted on Wednesday, September 11, 2013

now the question is did the pulley kill the belt or did the belt kill the pulley?

Or is it something else entirely killing both?

I would make sure that the wheel bearings and transmission output shaft bearing(s) are good.

For the drive belt to stay on the pulley(s); requires that the axle and transmission shaft centerlines are parallel at all times. |

Bluzm2

| | Posted on Wednesday, September 11, 2013 - 08:35 pm: |

|

Like I mentioned above (or maybe in a different thread...), ain't no way the new belt is going on without pulling the idler.

As Teeps said, it's REALLY tight. I too counted the teeth, I thought it was too short.

If you are the type to carry a spare I'd make sure to run the spare in for a bit. A roadside repair would be a nightmare with a new belt. |

Ratbuell

| | Posted on Wednesday, September 11, 2013 - 10:46 pm: |

|

I've installed a new belt without removing the idler.

I've also installed a used (spare) belt roadside without removing the idler.

As Froggy says...loosen the rear axle or remove it so you can slide the wheel up and forward, and it will install. I prefer not to remove, so I don't have to re-thread...

Yes, new belts are TIGHT. Which is why the spare I carry under my topcase at all times is used and slightly stretched.

Back on topic...I think a little walk one way or the other is normal, and its why the front pulley has a fence on one side and the rear pulley has the fence on the other side. That doesn't change the fact that the pulley pictured...is hosed. To get that bad, something was out of alignment for a long time...either that, or the belt in question was consistently ridden in sand, and it simply sanded down the pulley with time.

Kevlar belts WILL wear out aluminum pulleys, especially if there are environmental contributions... |

Road_kill

| | Posted on Thursday, September 12, 2013 - 08:08 am: |

|

My rear sprocket looked similar to yours, uneven wear and shinny. Only the original sprocket had a plastic coating on it, the others do not. The pn 12074 oil seal behind the front sprocket is easy to install once you get that darned sprocket off. That's the tough part. There is a tool to hold the sprocket stationary while torquing nut (see service manual for pn but it's a dealer only tool). Get one if you can. Other methods include holding the rear wheel from spinning (tranny in neutral) and a BIG breaker bar or impact gun (not preferred but ...) |

Uly_man

| | Posted on Thursday, September 12, 2013 - 12:39 pm: |

|

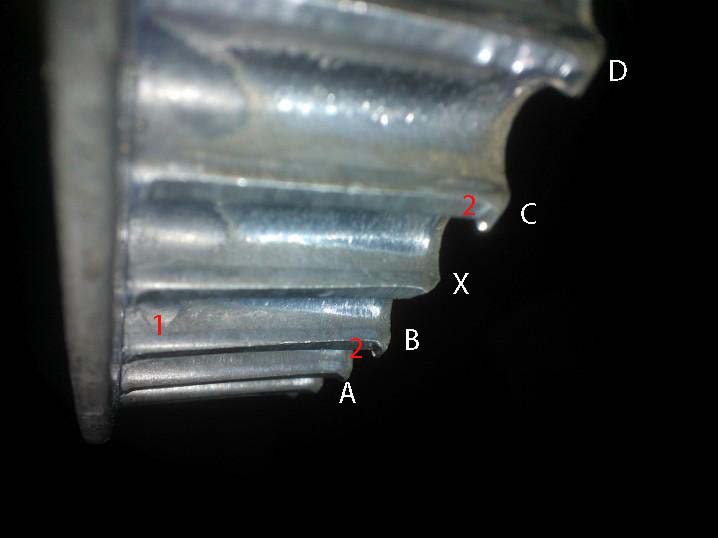

These pics show uneven wear of the sprocket.

If the belt tracks true it should not touch the shoulders of the front or rear sprockets as if it does it will wear the edges of the belt. I check the space between the shoulder of the rear sprocket and the belt edge with a credit card. The space should stay the same all the time.

If the idler pulley bearings are shot it might try and drive the belt out of true. Also the same with wheel, swing arm and engine output bearings.

The rear sprocket will get slight hooks on the edge so I file them off on a belt change. Also the paint does wear off as well so no worry on that. They should have used a steel sprocket IMO. |

Hughlysses

| | Posted on Thursday, September 12, 2013 - 12:46 pm: |

|

The pn 12074 oil seal behind the front sprocket is easy to install once you get that darned sprocket off. That's the tough part. There is a tool to hold the sprocket stationary while torquing nut (see service manual for pn but it's a dealer only tool). Get one if you can.

That's a BA nut too, something like 1-7/8" IIRC. I found a cheap 3/4" drive socket of the correct size at Tractor Supply, and luckily I have a 3/4" drive breaker bar. The nut is very thin (something like 1/2" thick) which makes it VERY easy for the socket to slip off, resulting in repeated knuckle impacts and much swearing. This is probably a good job for 2 people. |

Uly_man

| | Posted on Thursday, September 12, 2013 - 12:57 pm: |

|

"If the bearings behind the front pulley are out of speck (broken or badly worn), it could cause this. A bad seal at this bearing would seem to suggest a closer look at this bearing". So would I. This is a known issue on the early bikes if not a 08 bike. You need to check it as well as all the other bearings. |

Mattmcc00

| | Posted on Thursday, September 12, 2013 - 05:20 pm: |

|

my bike is a 2008 |

Mattmcc00

| | Posted on Thursday, September 12, 2013 - 05:22 pm: |

|

Also, i dont remember my rear sproket having any worn paint on the inside.

I beleive this to be new since the new belt went on... although i am only 70% sure about this.  |

Mattmcc00

| | Posted on Thursday, September 12, 2013 - 05:28 pm: |

|

Ratbuell regarding the little walk, I too think a little walk is fine. However, the issue here is that the belt is walking inwards untill it hits the frame and then grinds itself apart rubbing on the motoframe.

Actually its more like it grinds the frame. I have silver dust. |

Hughlysses

| | Posted on Thursday, September 12, 2013 - 05:34 pm: |

|

I don't think you're gonna find a bad bearing on the transmission output shaft. It seems that a bad bearing there would allow the shaft to shift slightly backwards under the belt tension which would cause the sprocket to skew slightly such that the belt would tend to walk outward, not inward.

Edit- apparently the nanny filter thinks c-o-c-k is only a bad word, not a word to describe misalignment, so I substituted "skew".

I'm holding out for defective belt.

(Message edited by Hughlysses on September 12, 2013) |

Motorfish

| | Posted on Thursday, September 12, 2013 - 05:54 pm: |

|

At around 5K miles my belt started walking off the rear pulley about 1/8". The dealer replaced it under warranty, said it was bad. It's been fine since, but I just put a new one on, at 17K, to keep the old one as a spare. |

Natexlh1000

| | Posted on Thursday, September 12, 2013 - 09:33 pm: |

|

So what are the odds that the belt is cone shaped instead of cylindrical like it's supposed to be?

If it is the belt, putting it on in the opposite direction should steer it off the other way, right? |

Uly_man

| | Posted on Friday, September 13, 2013 - 10:05 am: |

|

Looking at the picture again you can see the teeth are worn down on the outer edge and by ONE HELL of a lot.

Points A, B and C are NOT the slight "hooks" you can get but wear to the teeth and I would say point X is were the edge has broken off. Point 2 is much lower than point 1 but is is still worn down at point 1 as well. You can even see that the slightly rounded edge of the tooth is a sharp right angle. It looks like is has been attacked with a file.

That sprocket is toast and unusable. The wear "pattern" would make the belt track to the inside of the drive sprocket IE What it is doing. |

Mattmcc00

| | Posted on Friday, September 13, 2013 - 11:10 am: |

|

my order from Americain sports bike has already shipped and cleared customes in san diego according to tracking from USPS.

Should be here next week I'd Imagine.

I'll change both sprockets and the seal and see what happens. |

Uly_man

| | Posted on Friday, September 13, 2013 - 11:26 am: |

|

Cool.

One thing though is that your new belt is now damaged. It could be used but there some risk to that. If it was me I would use it as a spare but also use it to test that your new set up is tracking right. Good luck. |

Mattmcc00

| | Posted on Friday, September 13, 2013 - 01:02 pm: |

|

Thanks all I'll let you know in after i get this done.

Also, I think this might be the end of my Uly years.... Been riding more and more offroad and competing in offroad events to the point where my offroad abilities (or rather my willingness to push the bike into punishing terrain) seem to have exceeded the limits that my dear Uly can handle, and I can't afford 2 bikes.

Plus, I am no longer riding 2 up anymore, young baby means wife stays home and no more lovers road trips. So all that adds up to it being the right time to get an smaller nibbler off-roady.

Sooooo afraid that i'll never be able to get the same "grin factor" of a Uly, and spend the rest of my life nostalgic about my old Uly.

This photo is after climbing "mount everest" during the GS challenge. We were one of the only 6 teams to make it... out of ~42. |

Mattmcc00

| | Posted on Friday, September 20, 2013 - 09:53 am: |

|

Received my new front and rear sprockets, as well as tranny seal.

Going to do the job tonight.

Anybody know what size bolt the pulley has? I seem to remember 1"7/8 ? but not sure.

I'll need to stop by the industrial tools shop (oh darn  ) to buy the right size ratchet box, 'cus i don't own anything that big. ) to buy the right size ratchet box, 'cus i don't own anything that big.

Thx for your help. |

Hughlysses

| | Posted on Saturday, September 21, 2013 - 07:44 am: |

|

Matt- I checked my sockets; it is 1-7/8". You'll probably only find it in 3/4" drive, so you if you don't already have a 3/4" drive wrench, you'll either have to buy one or a 1/2" x 3/4" adapter.

As others said, the hardest part of the job is figuring out a way to hold that sprocket while you loosen the nut (and then re-tighten it). |

Danair

| | Posted on Saturday, September 21, 2013 - 12:42 pm: |

|

When I did my belt, I saw a couple of burrs right on the edge of a couple of the crowns. No prob I said, I'll just dress em out. NOT...put the file to it and it sang like I was trying to file carbide! That's some seriously hard aluminium, |

Mattmcc00

| | Posted on Monday, September 23, 2013 - 01:28 pm: |

|

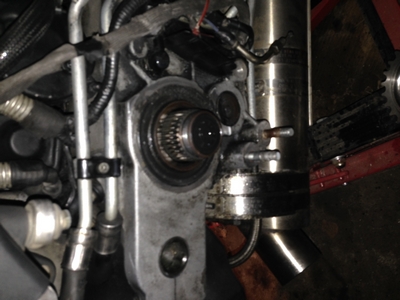

Ok so the job is done.

I installed new front and rear sprokets, didnt touch the tranny seal since it look top shape.

Verdict.... success!  belt tracks true now. belt tracks true now.

Regarding the box for the ratchet, I got one at the industrial tools shop with a 5 foot power 3/4 ratchet.

That's some serious tools

Had some difficulties getting the front sproket to stop turning. Ended up using the old snapped belt. Ended up screwing in the rear axel back in without the wheel, then Looped the old belt around the front sproket and then ran it back to the rear axel. Pinched the belt closed with some vise grips and a c-clamp.

Here are some pics of the job.

|

Mattmcc00

| | Posted on Monday, September 23, 2013 - 01:30 pm: |

|

here a pic using the big ratchet.

|

Mattmcc00

| | Posted on Monday, September 23, 2013 - 02:00 pm: |

|

off |

|