| Author |

Message |

Avalaugh

| | Posted on Saturday, October 16, 2010 - 08:33 pm: |

|

Thanks Z, I'll try the jumper method. Regarding the the propane gas, I would need the inner cover on, and poke the hose around the throttle bodies and then turn the gas on once the bike is running ? |

Zac4mac

| | Posted on Saturday, October 16, 2010 - 08:45 pm: |

|

Should be better removing inner cover and the base plate too so you can see where/if you get a positive reaction.

You need access to the entire intake tract to be sure, pay particular attention near the heads.

I'm still crossing my fingers for this, it's easy to fix.

Z |

Bextreme04

| | Posted on Sunday, October 17, 2010 - 04:16 am: |

|

The p0112 IAT fault is caused by low sensor resistance or a wiring issue. My best guess would be a bad IAT sensor, bad O2 sensor, and a break or short in the twisted pair wires for the IC data link. OR... it's all being caused by a wiring problem. I would suggest taking a look at your ecm and IC connectors. Does the maintenance manual have a wiring schematic in it? If so it should be fairly quick and easy to check for broken wires, a bad sensor, or a short to ground in the harness. Quick way to check the IAT sensor is to unplug it and hook a multimeter up to the wires with it set to check resistance. It should be a thermister with several thousand ohms of resistance. if it has less than 5 ohms then it is shorted internally and is bad, once you have a good stable reading put a lighter near it and watch the resistance to make sure it changes rapidly. If it doesn't change when you put heat near it then it is bad. As far as checking the harness i haven't seen a schematic of the electrical system so i have no idea what wires would need to be checked but you should be able to spot the datalink ones because they should be either a naked twisted pair or a twisted pair wrapped in a grounded shield depending on the type of databus being used, on the schematic they should be labeled as a J-xxxx where the x's are numbers denoting the type of databus being used... i.e. J1939 or J1708. |

Avalaugh

| | Posted on Monday, October 18, 2010 - 02:41 pm: |

|

Bextreme04 thanks for the info. I'm still trying to get my head round this order of diagnosis haha

I checked the IAT sensors resistance tonight and all is fine, connections behind the IC all seem fine.

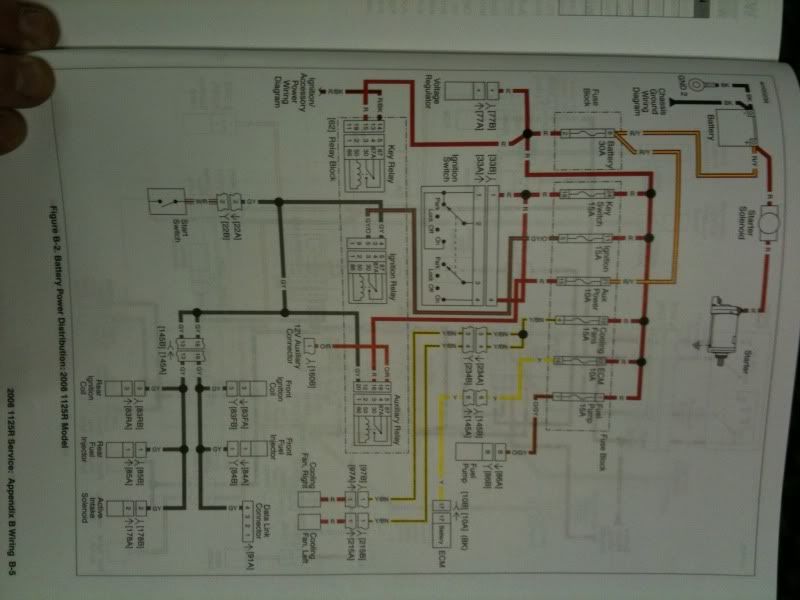

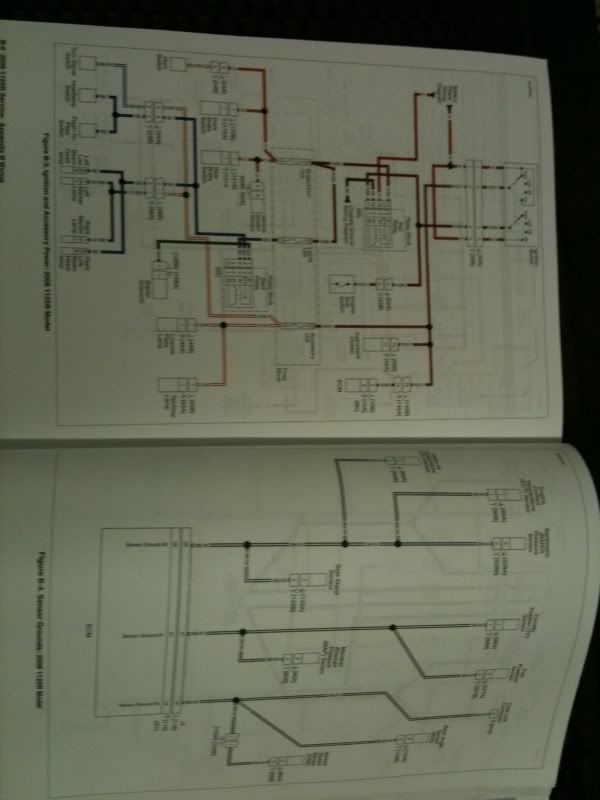

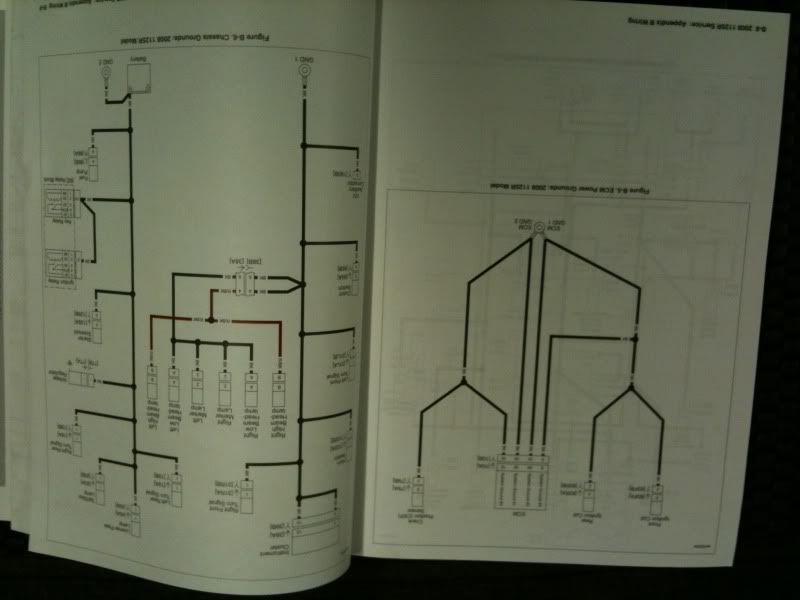

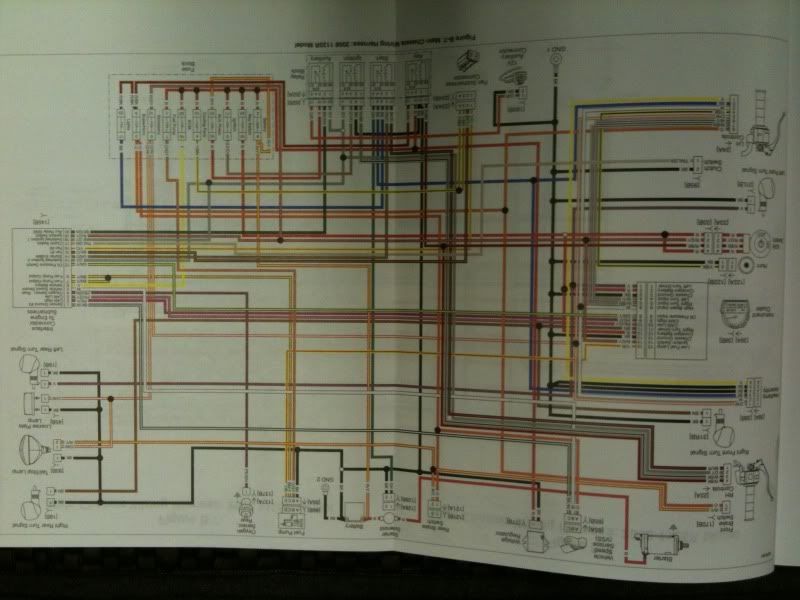

A number of weeks ago i took the bike to a dealer for the last of its warranty work, i installed the standard ECM for this trip and it threw no codes, was over a 100 mile round trip inc dealer test rides. So i'm pretty sure we can rule out the IAT and comms error code, but i will check those data cables coming from the IC as i now have the wiring diagrams.

I am going to email Erik Buell Racing about what codes i'm showing.

I'm also going to fit a rear O2 sensor.

I'm still thinking this is related to either the rear O2 being faulty, but then why would the standard ECM work and not the Erik Buell Racing one, the only reason i can think of is that there is a air leak and the standard ECM has adjusted to suit but in turn has thrown the code as it's out of the allowed parameters, and the Erik Buell Racing ECM does not use logged readings for the O2's so therefore never gets to the point of throwing a code or adjusting the fueling to run correctly like the standard ECM does.

So i need to find some PROPANE gas, but once i do, if i start gassing around the throttle bodies to see if the revs increase, as mentioned above i should remove air box completley, wouldn't the gas just get sucked in and in turn raise the revs anyway ????? |

Zac4mac

| | Posted on Tuesday, October 19, 2010 - 12:41 pm: |

|

Yes but you won't know where it got in, just that there's a leak.

Bigger reason to remove the baseplate is I don't like making explosive volumes of gas in a semi-restricted area.

Craters don't belong in the garage floor.

Set the propane for a low/slow discharge and hold the tip of the tube near each seal area.

You should be able to pinpoint it to a 1/4 inch spot or so |

Avalaugh

| | Posted on Tuesday, October 19, 2010 - 01:30 pm: |

|

haha, imagine that, a buell fireball in my garage

Haven't looked but does a gas BBQ use propane or butane ? and would that work as i have a gas bottle in my BBQ. |

Zac4mac

| | Posted on Tuesday, October 19, 2010 - 02:35 pm: |

|

Should work fine.

Just a flammable gas that's easy to work with.

I've heard of folks using water or brake cleaner and listening for a DROP in rpm, I like this way better.

A can of starter fluid(ether) with a spray straw works OK too, mind any painted areas.

Little squirts, not holding a steady stream. |

Avalaugh

| | Posted on Tuesday, October 19, 2010 - 03:34 pm: |

|

Thanks, ill have a play tomorrow after work, again  |

Bueller4ever

| | Posted on Tuesday, October 19, 2010 - 04:58 pm: |

|

Just buy a small propane torch from your hardware store. they are cheap. |

Bextreme04

| | Posted on Tuesday, October 19, 2010 - 05:28 pm: |

|

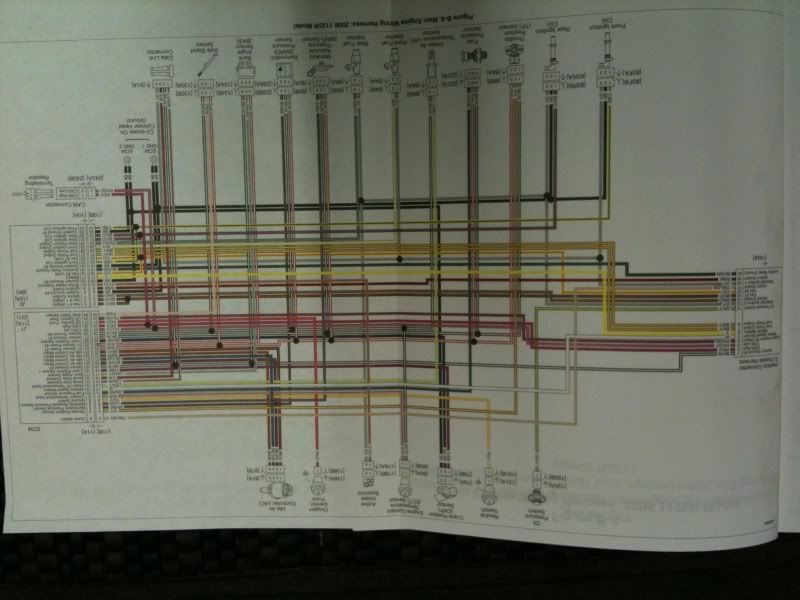

Ok.. so just to clarify what the problem is... You don't have any codes with the Erik Buell Racing ECM in but it runs really badly, with the stock ECM in you get all of the above mentioned codes but it runs great.. is that what the situation is? Also looking at the schematics i see the databus is labeled as CAN which means it's digital. There is a connecter in the bottom right corner of the last schematic picture you posted and the component after it is your databus terminating resistor.. it looks like the other one is on your DATALINK Connector just below them. Those resistors are absolutely critical to everything working right.. they catch the digital signals traveling on the datalink and keep them from bouncing around and running into each other. If they go bad it won't really give you a hard problem it will just start messing with all kinds of stuff and it will get worse and worse as more signals build up in the link until it finally crashes it. I think the writing to the right of the terminating resistor is telling you how many ohms it should be but it is too blurry for me to see. The ones for a J1939 are 120ohms so if it doesn't say then just pull them and check for 120ohms, if they have less than 5 or you get an OL then your resistor is definately bad and is most likely causing the problem. Sorry it's kind of just shots in the dark but it's really hard to troubleshoot from a distance when i'm so used to being hands on. The key is to figure out all the things that could possibly be wrong and then start eliminating them until you are left with the actual problem. You have already eliminated the IAT sensor and the IC connectors, now if you swap the 02 sensors and your AFV's don't change then it will eliminate them as the culprit. Intake leak definitely sounds possible although the biggest indication of that is usually a really rough idle and poor throttle response... i find that a can of carb cleaner works fairly well for leak tests, i just spray it around the intake track, injectors, and spark plug bases and see if the rpm drops... found a leaky o-ring on an injector that way about 2 months ago actually. My main suggestion would be to just write a list of all the things it might be and how to check them and then start checking them off as you rule that part out. |

Avalaugh

| | Posted on Wednesday, October 20, 2010 - 02:26 am: |

|

Thankyou very much guys, I'll update once I have checked out all the above. |

Zac4mac

| | Posted on Saturday, October 23, 2010 - 05:37 am: |

|

Paul - how's progress??

Z |

Avalaugh

| | Posted on Saturday, October 23, 2010 - 09:00 am: |

|

I'll be fitting the O2 sensor tomorrow, I used the propane but no change in revs, strangely, I also directed the gas into the rubber breather hose but that didnt cause any change either ? |

Zac4mac

| | Posted on Saturday, October 23, 2010 - 10:01 am: |

|

It shouldn't affect anything if there's no leak to fill.

I'll cross my fingers that the O2 sensor fixes your troubles.

Z |

Avalaugh

| | Posted on Saturday, October 23, 2010 - 11:18 am: |

|

Just taken a look at the O2 I have just bought second hand, it's got a short lead on it, if I join and extend it will this effect the sensor or is it not just a copper core inside ? |

Avalaugh

| | Posted on Saturday, October 23, 2010 - 12:49 pm: |

|

The one on the right of the picture (orange in colour) is the original sensor and the left one is the second hand one i have bought. Does this look normal ?

Also i have found the cause to a vibration i have had for a while in the left footpeg. The bolt which secures the exhaust to the left footpeg assembly had broke.

|

Avalaugh

| | Posted on Tuesday, October 26, 2010 - 02:51 am: |

|

Well got the new sensor fitted, I just extended the cable. Went out for a short ride, but never got round to swapping the ECM over as my brother broke his leg so had to go to the hospital. Will try again at the weekend. Also can a dealer just delete the codes and reset the the 02's ? I hope I get to the bottom of this soon  |

S21125r

| | Posted on Tuesday, October 26, 2010 - 10:49 am: |

|

With the old version of ECMspy and Tuner Pro you can reset the codes and rear AFV. New version of Spy has the ability to reset the front AFV as well, but don't quote me on it.

Dealer can do this as well, but they may charge for it. You might be better off spending a few bucks on a cable to do it yourself. Based on what you've investigated/reported thus far, it obvious that you are not a "Cole Trickle" type so you shouldn't have any problems learning Spy or Tuner pro. |

Avalaugh

| | Posted on Tuesday, October 26, 2010 - 12:13 pm: |

|

Was thinking about getting the software so might as well. I presume I can download it for free somewhere, but where can I get the cable from please ? This bike will be the death of me lol |

S21125r

| | Posted on Tuesday, October 26, 2010 - 04:02 pm: |

|

Xopti might have some cables on his site. Probably find them on fleebay too. I bought the bare Serial to TTL cable and plug separately by searching for part numbers on this site, and the ECM Spy site. Can't find the links to the supplier I bought from, but if I find them, I'll shoot you a PM. Don't think i spent much more than 25-30 bucks and about 10 minutes assembling. Trickier part is the cable driver load - scratched my head for a day or two before I got it connected. |

Froggy

| | Posted on Tuesday, October 26, 2010 - 08:43 pm: |

|

American Sport Bike sells the cables too. |

Avalaugh

| | Posted on Monday, November 01, 2010 - 02:36 pm: |

|

Thanks for all the guidence guys, i got a bit carried away this weekend and decided to start the front end conversion so all fault finding/testing has gone on hold until the new year. I will have a play with ECMSPY and once its all up and running again i'll report back.

This is how it looks at the minute

|

Chameleon

| | Posted on Wednesday, November 03, 2010 - 02:55 pm: |

|

I haven't heard this mentioned yet, but could it be a bad injector?

Swap the front & rear injectors to see if the problem moves. |

Avalaugh

| | Posted on Wednesday, November 03, 2010 - 03:49 pm: |

|

i'll do that too, thanks |

Chameleon

| | Posted on Thursday, November 04, 2010 - 01:13 pm: |

|

Use the scientific method and only change one thing at a time, then test and document the change. |

|