| Author |

Message |

Jerseyguy

| | Posted on Wednesday, April 07, 2004 - 03:03 pm: |

|

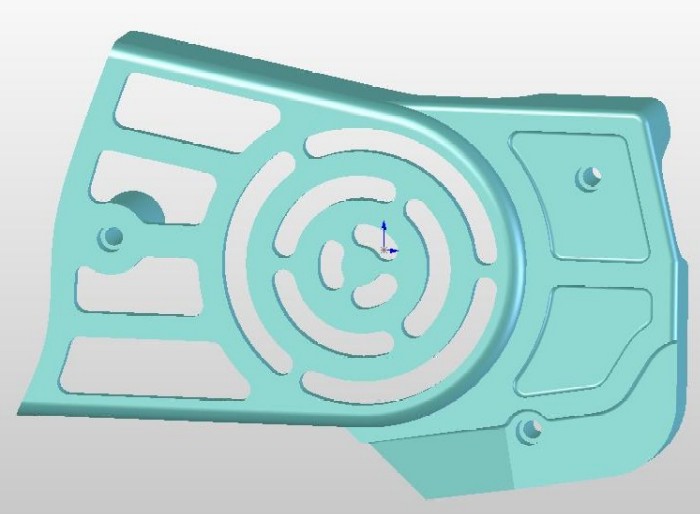

What do you guys think of something like this? I let form follow function a bit more than the folks above did in their design. This one is fabricated from one piece of billet Al. Personally, I can't decide which style I like better. The "skeletonizing" can take most any form. I may model a few different patterns.

As a low end alternative, I could skeletonize the stock plastic cover.

Steve H. |

Bomber

| | Posted on Wednesday, April 07, 2004 - 03:04 pm: |

|

Geof

back atacha |

Geofg

| | Posted on Wednesday, April 07, 2004 - 03:21 pm: |

|

Jerseyguy,

Looks nice! I could definitely see it w/a painted pulley skin behind it. That'd make some fun moire patterns with the cutouts you've got going.

-Geof |

Glitch

| | Posted on Wednesday, April 07, 2004 - 03:45 pm: |

|

Wow, that looks nice!

And you could cut any design into it.

Oh the possibilities... |

Al_lighton

| | Posted on Thursday, April 08, 2004 - 01:12 am: |

|

Steve,

Crank up the mill! I'll buy a bunch from you. That one is smoother than the crossroads pulley guard that we currently sell, shown below. One nice thing about the crossroads one is that it uses the Kuryakyn plates that come from their hyperchargers, and they are available in about 14 different colors.

One caution: That plastic stock part is a little different in the 2004 version than the 2003. The 2004 guard won't fit on a 2003 bike without chopping off a tab, but I'm not sure if the converse is true. It isn't 100% clear if that tab is there on your CAD 3d model or not. I suspect not since it appears to follow the 2003 lines. I suspect most 2003 models will eventually get a 2004 belt conversion some time during their life, and it would be a bummer to have to throw away a nice guard at that time. Just a thought.

edited by al_lighton on April 08, 2004 |

Gonen60

| | Posted on Thursday, April 08, 2004 - 07:55 am: |

|

not digging the color coded one to much. needs to be more "open" looking.. |

Jerseyguy

| | Posted on Thursday, April 08, 2004 - 08:21 am: |

|

Al,

The tab you are referring to - Is it on the lower rear corner just above the tensioner pulley? If it is, I left that feature off as I didn't think it was worth the extra machining time. It's purpose looks to be a safety cover for the in running nip point between the belt & the pulley. Since we are opening up the guard in general, safety isn't a big issue. Otherwise I was faithful to the original design functionality. I especially tried to maintain as much coverage in the front over the electrics to shield any direct splash off of the wires & connectors.

As to the esthetic design, I could machine lightening bolts, "USA", "BUELL" or whatever looks good and has enough mechanical integrity. This design attempts to follow the flow of what's going on underneath.

Annony - If you should happen to read this, please give my compliments, from one CAD jockey to another, to the guy who designed the plastic cover. I feel his pain in getting everything to fit & look good too.

Steve |

Bomber

| | Posted on Thursday, April 08, 2004 - 08:38 am: |

|

Looks like you'repulley skins are available, gents! not much point in firing up the latche if they're available and, er, affordable . . . ..

Al, zat pulley skin available on it's own? |

Henrik

| | Posted on Thursday, April 08, 2004 - 09:18 am: |

|

Jersey; great looking cover! I guess one could carve a Pegasus in that cover?? Or make the cut-out circle match the wheel design.

Henrik |

Jerseyguy

| | Posted on Thursday, April 08, 2004 - 10:51 am: |

|

Henrik - Cool ideas. |

Easyflier

| | Posted on Thursday, April 08, 2004 - 12:57 pm: |

|

I like the idea of a Pegasus Henrik.

Also for inspiration look at some custom grills for computer cooling fans. Here's a couple examples http://www.mysterybyte.com/itempics/cooling/sm-80mm.gif http://www.mysterybyte.com/itempics/cooling/pun-80mm.gif |

Geofg

| | Posted on Thursday, April 08, 2004 - 01:06 pm: |

|

Bomber,

Don't give up on us yet, the pulley skin is the key for showing off the open shroud.

-Geof |

Easyflier

| | Posted on Thursday, April 08, 2004 - 01:44 pm: |

|

Here is a site that has a nice assortment. http://www.jab-tech.com//customer/home.php?cat=48

This thread has me thinking about modding my plastic cover for the time being, thanks for the inspiration. I like jerseyguy's concept and the crossroads design, both are nice choices. |

Bomber

| | Posted on Thursday, April 08, 2004 - 02:05 pm: |

|

Geof . . .not givin up at all, but I figured if the skins shown above were available for $5, that'd be the way to go . .. . I"m sure they are at least a little more than that .. . . .

anyways, will be working on these as the e-mails stated . . . .. |

Jerseyguy

| | Posted on Thursday, April 08, 2004 - 02:08 pm: |

|

Easy, Those fan grills are pretty cool. Keep in mind that when endmilling interior corners the sharpest corner you can get is the diameter of the endmill. We can EDM here too, which has no limit, just like the laser cutters they use. It only takes money ......

I've been thinking about doing my plastic cover too. The existing design esthetically locks you in to only a few options. I have to think about it some.

|

Easyflier

| | Posted on Thursday, April 08, 2004 - 02:29 pm: |

|

I was thinking the billet covers with the ability to change out the grills.

Similar to crossroads, just make it with a hole and the means to fasten different grills, might even simplify the milling procedure that way, though I'll leave it up to people like you that work with it.

But for now I'm seriously thinking of taking a Dremel to my existing cover when the weather is crappy and I feel creative, and fasten one of the computer grills to it. Might look kinda cool. |

Jerseyguy

| | Posted on Thursday, April 08, 2004 - 02:49 pm: |

|

Geofg - The "pulley skin" could be just a drawn cup made from say 24 GA stainless. I bet Kevin could make one by hand. |

Geofg

| | Posted on Thursday, April 08, 2004 - 04:54 pm: |

|

Jerseyguy,

That'd be fine, too. I'm really just looking for something nice to cover up the rust and show off the pulley.

I especially like that the belt tensioner and the pulley spin in opposite directions, so I was thinking of painting the pulley skin and the belt tensioner to accent that somehow.

-Geof |

Bomber

| | Posted on Thursday, April 08, 2004 - 05:06 pm: |

|

Jersey -- sure could . .. I'm a little concerned, though, if you use the pulley locating plate screws to attach the skin, you'd have a far amount of unsupported fastener that MAY (emphasize may) be subjected to a great deal of shearing forces . . . .

the pulley "skins" I've seen for the tubers are actually much thicker, and darn-near contact the shaft and nut, keeping the length of the unsupported fasteners very short indeed . . ..

am I makin sense? making a "skin" would be a lot easier than the other way, for sure |

Jerseyguy

| | Posted on Thursday, April 08, 2004 - 05:54 pm: |

|

Bomber - Maybe I don't understand you, but my type of cover would be held on by the big nut that holds on the pulley. |

Bomber

| | Posted on Thursday, April 08, 2004 - 05:58 pm: |

|

Jersey. . . .got it . . . I was thinking of something that would he held on by the little bolts that attach the little sheet metal thingie that keeps that big nut from turning . . . . .. I'm thinkin easier install frlo those that don't want to break that big nut loose . . . . |

Al_lighton

| | Posted on Friday, April 09, 2004 - 03:10 am: |

|

That "pulley skin" on the crossroads billet pulley guard are the same part as the the Kuryakyn Air filter covers. They do not attach to the pulley itself, they are mounted on the billet cover. See http://www.kuryakyn.com/products.asp?bn=harley&ci=474

I can get any of them at the same price as they show there.

Joiseyguy, yea, that's the tab that is causing interference problems. I think you've got it by leaving that off, but I need some additional fitment time on both an 03 and an 04 to know if that's the only issue.

Al |

2k4xb12

| | Posted on Friday, April 30, 2004 - 08:26 am: |

|

Dave,

Which one(s) do you carry? Got a photo or link? How much $$?

Thanks! |

2k4xb12

| | Posted on Friday, April 30, 2004 - 08:27 am: |

|

Yes, if you were to look at the profile of the cover, there is a 0.375 difference in height between the mounting surface (the locking plate) and the edge of the pulley. Also, there needs to be a relief of the same depth, about 2" in diameter in the center (I would have to check again to be sure, but it's to clear the shaft nut. If you don't have a bike to reference there, I can draft something up on AutoCAD if you have the ability to read the files...

Steve.

|

2k4xb12

| | Posted on Sunday, May 02, 2004 - 08:37 pm: |

|

Whoa -- what happened there? These two previous posts were from the first week of April, but now I see them reposted with dates of 4/30 and only a minute apart ???

Do I detect a system hiccup at fault? |

|