| Author |

Message |

Garlic_sauce

| | Posted on Thursday, May 28, 2009 - 06:28 pm: |

|

I made the plates and had the rearsets on but I couldn't get it to shift properly (too much throw) because of clearance issues. They either would have to be way too far up or down. I jumped the gun trying to set them up when I first got them and really didn't think things through. For now I just set them up mmelvis style and I'm happy, kinda. The peg shifter arm that comes with the sets is just too short to use with engine plates. What I am working on now is to go with my first idea and make new arms that come off the frame, that way there will be no clearance issues and I will be able to put them wherever I want. It won't be for a little while though since I missed so many nice riding days while my bike was down. |

Kenster32

| | Posted on Thursday, May 28, 2009 - 06:52 pm: |

|

i hear ya im relucktant to tear into it till winter its a long up here

but just making a photo copy of the cross-roads to get all the screw holes positions and then make something in a better position

i can use all the hardware from the c-r

and cut new from aluminum

how many aluminum street signs to get the right thickness??

no milling required |

Garlic_sauce

| | Posted on Thursday, May 28, 2009 - 07:54 pm: |

|

Kenster, If you make new plates I would love to buy your cross-roads plates from you. |

Kenster32

| | Posted on Thursday, May 28, 2009 - 08:08 pm: |

|

i was hoping some one would

i wont be at it to soon thou

docs cuttin up my shoulder next week so it will be a while

i was sirius about the multi layers of aluminum street signs i found some at work and 3 layers would do and easier to cut 1 at a time |

Garlic_sauce

| | Posted on Thursday, May 28, 2009 - 08:15 pm: |

|

Oh yeah I was thinking of that when I was at Lowes, They had some sheet aluminum. I can wait for the plates, Just let me know when your ready and I will definitely buy them from you. Good luck with the surgery man, what is it for rotatory cuff? |

Kenster32

| | Posted on Thursday, May 28, 2009 - 08:30 pm: |

|

bicep tendon tearing off the bone

and fraying rotator and bursa cleanup

iv had the others surgery before but this is my first time iv tried to tear it off |

Garlic_sauce

| | Posted on Thursday, May 28, 2009 - 08:39 pm: |

|

Damn, how did that happen. |

Gearheaderiko

| | Posted on Friday, May 29, 2009 - 11:29 pm: |

|

1/4" aluminum plate cuts easy with your standard jig saw and is thick enough for engine plate mounting. I bought 2 12" square pieces (or 2 sq ft!) for $20. Its not that hard or expensive! You just need to find a metal supply place and there are also places where you can order online (actually a place is listed somewhere here at the Thumper side-I have the link on the old fried computer) |

Gearheaderiko

| | Posted on Friday, May 29, 2009 - 11:36 pm: |

|

http://www.badweatherbikers.com/buell/messages/201 64/442102.html#POST1384669

or

onlinemetalsupply.com

Thanks krjoseph! |

Krjoseph

| | Posted on Friday, May 29, 2009 - 11:38 pm: |

|

I used 1/4" plate also. It's actually really easy to build your own. Just takes some time and basic skills. I got my plate from onlinemetalsupply.com. |

Garlic_sauce

| | Posted on Saturday, June 13, 2009 - 04:05 pm: |

|

UPDATE

I made some major headway in my frame mounted rearsets, lets just say I found some parts that haven't been around for a while. Pics coming soon. |

Kenster32

| | Posted on Monday, June 22, 2009 - 03:49 pm: |

|

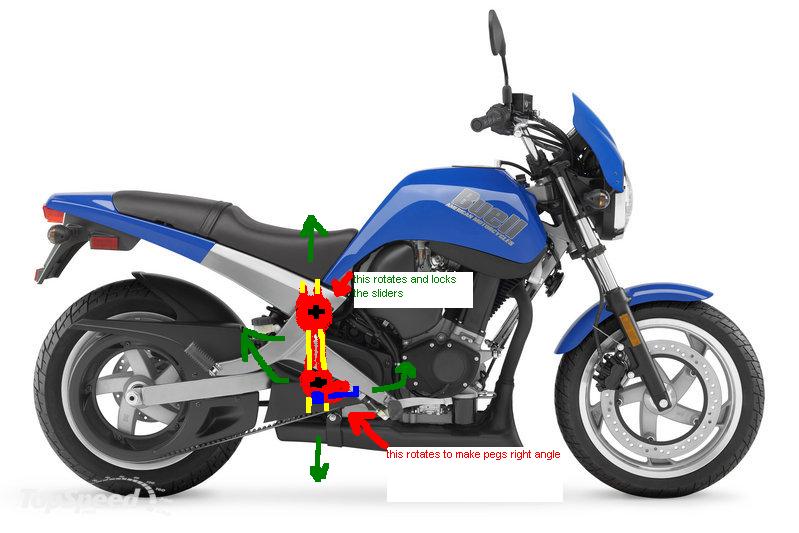

i figured this out today at PT looking at a exercise machine its rear sets that will fit blast and adjust in seconds to any riding position forward or back up or down--the top red rotates forward or back and and lets the yellow sliders up or down and is locked down by the black cross -- bottom red rotates pegs (blue) and adjusts sliders and is locked by black cross

if both rotators had positioning teeth that were numbered you could set it back just the way you like it for street ,race ,cruising

you could replace yellow sliders with longer or shorter rods for extreme adjustments

the shifter could have an adjustable rod for quick readjusting

i thinks its pretty Dam Slick any opinions???i think if mill work was not stupid expensive it would be very doable

|

Gearheaderiko

| | Posted on Monday, June 22, 2009 - 09:28 pm: |

|

An idea that certainly has merit but the machining costs...oh boy!

Needless to say I have already worked up that solution. It involves much of the same principles and I already have the parts (aftermarket and stock Buell parts) but havent implemented it.

The raceBlast tends to get any new parts and modifications and the streetBlast gets put on the back burner. I've had the parts (actually many parts) for a few years now! |

Reuel

| | Posted on Saturday, June 27, 2009 - 12:21 am: |

|

A dremel or two and 300 cutting disks might do the trick! |