| Author | Message | ||

Oldog |

IF you have to replace your PM wheel bearings the best place to get them is AL but If you pressure wash you bike like I do mine keeping them in tact and greased is still an issue, the front bearings are dead at ~ 40 K miles ( they are in better shape than the stockers at 15K were ) I regreased them and in theory could make them last a while longer, [ not a good idea ] I had a suzuki that at 50K had never had any issue with the wheels or bearings, one primary difference was the spacers had a shield that sat just off of the seal and covered it with out touching it, I always put grease on it on re install and I believe that this may be a solution to wheel bearing issues, here are the drawings | ||

Oldog |

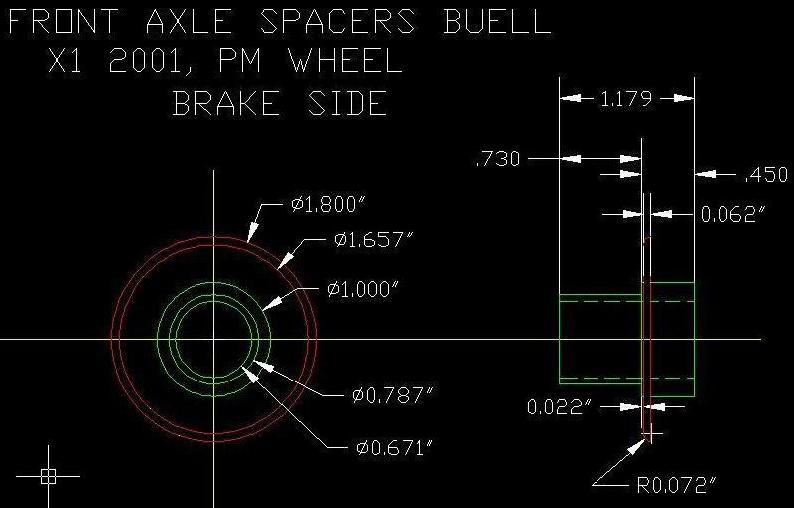

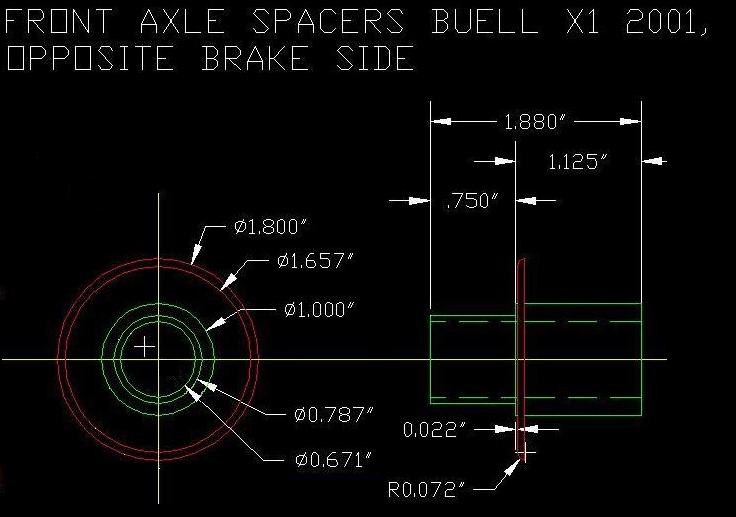

after much fiddling   the red flange is the change to the spacer, If I had access to a lathe Mine would be made of steel, the aluminum ones were difficult to remove this round Note I took my measurements with dial calipers and these could be out of best fit by .005" bearing to spacer and spacer to axle is a "close" slip fit the proper fit can be taken apart with the fingers but has no detectable play, my guess is that the larger diameter shoulder is the crucial length as it positions the wheel in the chassis. If any one would be interested in making me a test set from steel or aluminum please PM me at X1_rider AT live dot com I will pay for your metal for the parts the flange should miss the bearing by about .022" ( a random number ) the OD shoud be smaller than the od of the bearing the rear bearings are much better protected. and don't seem to need this | ||

Oldog |

the rear axle spacer is 6.687" the front axle spacer is 2.946" | ||

Buellistic |

You must use the proper "TORQUE" on the AXLE NUT or you will be waisting you money on bearings because if over tigten'ed the will not last ... Proper TORQUE for my 97 S3T is 66-73 ft. lbs. ... If the axle nut stays tight at 66 ft. lbs. there is no need to tighten it any more ... | ||

Oldog |

I had issues with the rear axle slipping in its mount after I had painstakingly aligned it to less than .005" of square and checking it later to find it had moved.  the front axle is spaced on aluminum spacers I don't know what the correct torque is but they did not want to come out of the wheel bearings, I presume that I over tightened them too. and I found an abraisive black grit in the front wheel bearings so I am changing them out, And I want to get these shielded spacers made.  | ||

Buellistic |

Front axle nut for my 97 S3T is 48-53 ft. lbs. ... | ||

Oldog |

bump | ||

Gowindward |

Ever consider just press fitting washers onto the axle spacers. Might be a home shop method of fabrication without a lathe. | ||

Oldog |

Yes the size of the washer is the issue those should miss the set back on the opposite brake side, and shield the bearings from direct blasting from water & dirt, | ||

Gowindward |

Look at these. Might be a cheap method and have some flexibility on fit. http://www.mcmaster.com/#93783a051/=cd2ye | ||

Oldog |

do you think that they would stay put, the install includes greasing the side facing the bearings and maintaining a close spacing but no contact, I like it and may try it | ||

Gowindward |

At $3.86 each it's worth a try. Another option may be a split collar. http://www.mcmaster.com/#split-collars/=ce9ks (Message edited by gowindward on January 27, 2009) | ||

Oldog |

the two if there are no interfeerinece(sp) issues may be an approach the area that these fit in near the wheel is kinda tight I have a local shop thats slow looking at it. I'm thinking about 120$ for the set in aluminum 2+ hours time NOTE I just caught an error on the drawings the OD of the flange 1.8" and smaller will be ok the bearing is about 1.850" the bearing is 20 x 47 mm IIRC (#6204) leaving .020 radial clearence on the obs this is too close IMO (Message edited by oldog on January 27, 2009) | ||

Jramsey |

Oldog Sorry I haven't gotten back to you sooner. The 'ole lady's been sick the last week and off work and I take care of my 89 year old mother twice a week, she has Alzheimers. Plus we got 1/2" of ice last night and 2" snow today. I'm tied up till Thursday with projects but have no problem making your spacers Friday. If a 1.750 on the flange would be acceptable instead of 1.800 I have plenty of 4130. You have a PM. | ||

Xldevil |

Oldog,what did you mean if you say that the axle is not square? How did you measure that? Iīm interested in that because I recently changed my rear wheel bearings and itīs impossible now to get my belt aligned,not when I turn out both axle adjusters bolts to the same distance.The belt has the tendency to move a little slant at the front pulley.It now moves to the lateral side Actually I would have to unscrew the left adjuster bolt 2 mm more than the right to get rid of that.Never had that issue before. Ralph | ||

Buellistic |

SWING ARM BEARINGS GOOD ??? You have to adjust the axle adjusters to where the Drive Belt runs in the center of the sprocket "OR" like on the BLAST/XB models one has to move the sprocket in or out from the wheel ... On my BLAST "i" had to move the sprocket out away from the wheel to get the Drive Belt to run in the center on the sprocket(flat washers did the trick) ... IF THE SPROCKET BOLTS SHOULD REACH THE LENGTH(DEPTH of threads)INTO THE WHEEL ... | ||

Oldog |

JR, It sounds like your plate is running over! You sure that you have the time to fool with this? 1.75" dia od is fine, IF you have time.. | ||

Oldog |

Ralph the allowable variation from square 90 degrees, is .015" or about .4 mm variation in space left and right, measuring the adjuster pocket to adjuster space I am a little confused Ralph I am with Buellistic the swing arm may be off center in the mount or the bearings may be bad | ||

Xldevil |

Swingarm bearings,adjusters and isolators were changed during the same surgery  Maybe the swingarm isnīt well aligned,even though I tried.I will examine that again. Ralph (Message edited by Xldevil on January 29, 2009) | ||

Buellistic |

Sometimes it is what has just been touched ??? | ||

Oldog |

Hey Ralph! I have had the arm out several times, and thinking about centering the arm, you set the pre-load on the bearings then clamp the "plugs" into the mount, I just position the mount until its flush with the outside and if needed split the difference side to side. Your comment has me puzzled. | ||

Xldevil |

if needed split the difference side to side. Thatīs how I did it myself,too. I couldnīt position the plugs flush because Iīm using an upgraded construction of that,made by Luckyhands.The plugs are slightly longer,bigger and the inner threaded adjuster rod is not so fragile like the BMC part.All in all this construction is stiffer but lighter by the use of better aluminum and doesnīt change itīs size and thereby swingarm bearing clearence while the engineīs heat is transfered to this area  At the top you can see the Lucky part (Message edited by Xldevil on January 31, 2009) | ||

Xldevil |

You need different bearings of course,as the ID of the new bearings has to be wider too.   | ||

Jramsey |

Oldog, you have a PM. I need your address. James (Message edited by Jramsey on February 01, 2009) | ||

Buellistic |

BUELLers: The rear wheel is supposed to follow the front wheel(tire center for tire center), NOT BE IN THE OTHER WHEEL RUT !!! Guess you'll have never seen a car with the rear wheels to the right or left of the front wheels going down the road ??? | ||

Jramsey |

Oldog, I see your online. Bump. | ||

Oldog |

Jr you got mail! | ||

Jramsey |

Oldog, package on the way, post office said Wed. delivery. | ||

Jramsey |

Oldog, you have another PM. | ||

Oldog |

I will check the bill box tonight Eagerly looking forward to the goodies perhaps getting the front and primary cases sorted saturday afternoon. | ||

Oldog |

James They came in Friday SWEET! I had a tough time installing them because they were sooooo pretty I just wanted to fondle them I got them on saturday PM I had to deal with a friends "DRAMA" saturday, the fit could not have been better! I cleaned them with some brake clean and rattle can black, I am having to replace the HID ballast =( I will post up your pix later this week I have some BWB stuff to deal with. James man I have GARAGE ENVY BAD! you got some sweet digs...  |