| Author | Message | ||

New12r |

For those of you who have had the throttle break OUT OF WARRANTY how did you resolve the problem? Did you get just a shaft? Did the dealer or Buell goodwill the repair? Did you have to shell out $500 to get a whole new T body? (absolutely freaking ridiculous if you ask me) I have a pretty good plan of action but I need to be rolling sooner than later, and having not a dime to my name and two other mouths to feed makes this really tough. Somebody buy my XB wheels so I can at least get my truck running. http://www.badweatherbikers.com/buell/messages/21/ 427117.html?1232071385 I have an 06 Uly with 26k and this is the first time any of my Buell's has let me down. | ||

Ft_bstrd |

Are you talking about the center shaft to the butterfly in the TB? From what I understand, you can not buy just the shaft. | ||

New12r |

Yes, the center shaft. The bike ran fine wed, and I left it at the shop till this afternoon. I went to start it and it backfired and sputtered, the usual start in really cold weather. After the big backfire it started right up the next starter hit and idled at 2200rpm and I thought that is odd. I finish gearing up and go to leave even though the idle was still wayy high, the bike was warm so I knew I should be fine, well that was when I noticed I had no throttle. I NEVER TOUCH the throttle on a start until the heads feel warm to the touch(learned the hard way) so I was ready to roll when I noticed it. I have found out I cant get just a shaft from the dealer, so it looks like I might get the "shaft". I sure hope I can find a solution to the problem because the cost of the t body is retarded. | ||

Wheelybueller |

EMS warranty,5 year 18,000 miles. | ||

Ft_bstrd |

I think this is going to be your best bet: http://cgi.ebay.com/ebaymotors/BUELL-XB12R-LIGHTNI NG-FIREBOLT-THROTTLE-BODY-INJECTION_W0QQcmdZViewIt emQQ_trkparmsZ72Q3a1205Q7c66Q3a2Q7c65Q3a12Q7c39Q3a 1Q7c240Q3a1318Q7c301Q3a1Q7c293Q3a1Q7c294Q3a50QQ_tr ksidZp3286Q2ec0Q2em14QQhashZitem380087178867QQitem Z380087178867QQptZMotorcyclesQ5fPartsQ5fAccessorie s | ||

Paul56 |

Dr. Greg might have one! | ||

Midnightrider |

Happened to me a couple months ago on the Uly. Short story - out of warranty, out of luck. I tried Buell Customer Service (twice) but they did not step up. | ||

New12r |

I saw DR gregs thread. Ebay may be my best option but I can tell you now I am plain pissed. I totaled my firebolt twice and never had a failure beyond what I broke crashing it. I have no means of transpo without leaving my wife and kid stranded. | ||

Ft_bstrd |

I believe that part should have been covered or recalled. There was obviously something wrong with it. Shoot Court a PM and see if there is anything that can be done. | ||

New12r |

Stone Mountian is going to place a call to Buell for me monday, I am going to place a call to Buell Monday as well. If all else fails I may give court a shot. Wheely, I put 18k a year on my bike. I love my dealer and all but NO ONE touches the bolts on my bike but me, EVER and that is precisely why my bikes last. I have seriously considered opening a Buell repair center but too many of us do all our own work and I dont see being profitable. | ||

Hughlysses |

Charlie- I have seen broken throttle shafts repaired by brazing before (a guy my dad worked with did it for a Tillotson carb on a go-kart I had when I was a kid). If you've got a friend with access to a machine shop it wouldn't be that hard to make one. Just trying to throw out other possibilities. | ||

Stevem123 |

Hey New12r, Can you post a picture of the broken part? My 06 Uly now has 32K and has always had a little stiffness to the throttle return such that when the bike is not running it will not return on it's own without help. Running it works fine probably due to vibes etc. I've not investigated it and loosly attributed it to the sharp bends in the cables due to the location of the TB and how the cables route but now I'm a little worried. BC Steve | ||

Wheelybueller |

A good machine shop should be able to build a shaft that will never break. Make a shaft that is not machined flat but instead was slotted,this would double the surface area and possibly eliminate the "stress riser" on the ends. I dont have the equipment,or the knowledge. Any machinist chime in,would it be worth tooling up to make a few?? | ||

Dio |

Midnightrider - How many miles and what year? Is this going to be the next "fly in the ointment" issue? | ||

Ft_bstrd |

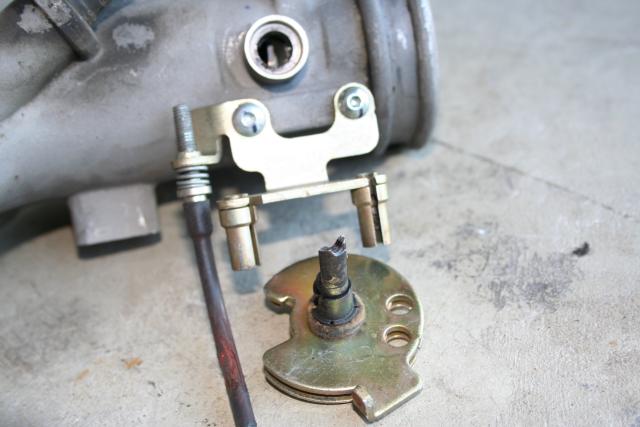

Here is what it looks like:    http://www.badweatherbikers.com/buell/messages/384 2/379951.html?1220129197 | ||

Midnightrider |

2006 Uly with just under 15K at the time | ||

Bobbuell1961 |

Fat b, brings back ugly memorys, mine looked like that at a little over 30k. i bit the bullet and replaced the entire throttle body which was on back order at the time (appleton had 3 in stock at the time!thanks) just wondering, were you able to retrieve the 2nd screw? mine was still attached to the shaft | ||

New12r |

Mine looks just like that, I got both screws out though. Keep in mind I am an auto mechanic by trade so pulling screws is what I do best. Mine also broke at startup so the bike never moved. I am going to check with a pal about the machine shop idea. IF I can do it I may have a few made just in case. | ||

Rwcfrank |

I would be more concerned about where the chunks went..... | ||

Ft_bstrd |

I'm wondering if when the TPS resets are being done and the screw is turned all the way in if it's putting too much pressure on the shaft. There has to be some reason that these are breaking. I can't imagine that there is enough force from rolling the throttle to snap them off. | ||

Bobbuell1961 |

i've seen a few HD break at the same spot, no TPS reset there | ||

Teeps |

I would be real surprised if Buell does not step up and do the right thing. | ||

Rwcfrank |

That really looks like a fatigue break. Probably from vibration. | ||

Tootal |

From what I see in the picture there is also damage to the bearing surface of the aluminum TB. This might be able to be reamed out and a bronze bushing installed. A new shaft should be fairly easy to make in a machine shop. Any pictures of the shaft alone? I think the shafts are plated steel which means they would need to be undercut before plating. Stainless would probably work harden and break from vibration. A non plated shaft would rust. | ||

Hughlysses |

You can see above that there's not a lot of "meat" in the area where the throttle shaft breaks. The sharp threads act as stress risers in the area as well. Figuring out a way to provide more metal in this area is one way to help prevent breakage. Another idea would be to make it out of a stronger and more fatigue resistant material. Wheelybueller's idea of slotting the shaft and inserting the butterfly through the shaft makes a lot of sense. Might be difficult to cut a slot that thin however. It would also result in slightly more flow restriction at wide open throttle. There appears to be plenty of metal in the throttle body if you wanted to make a larger diameter shaft. You could ream the existing holes oversize and then make a shaft to match. The next trick will be how to attach the widget for the throttle cables to the end, but that should be pretty simple to figure out. | ||

Wheelybueller |

I have discussed this with the machine shop I use,He states it can be done. Some old dirtbikes and sleds use a round throttle shaft. If someone has a bad shaft they no longer want I would present it to him and see what he could do. I dont think it would be cost prohibitive,if he were to make a couple back to back.  | ||

Wolfridgerider |

I saw the same thing at Homecoming last year..... now I've got this to worry about.... Hope you get it up and running soon! | ||

Jlnance |

Figuring out a way to provide more metal in this area is one way to help prevent breakage. What affect on the stresses would applying a thing bead of JB Weld between the shaft and the plate have? | ||

Rkc00 |

What is the cost of a new throttle body? Is it $500? Can this be removed and replaced from the top without rotating the engine? The reason I am asking is I am thinking about getting a new 09 XT. I would rather put the money towards the new purchase than have a $1000 bill to fix this from the dealer. I am getting close to 30000 miles and don't need this happening to mine. Mike Long Island, NY 06 XB12X Red/Black | ||

Tootal |

No need to rotate. Remove air cleaner box, air scoop and right side cover. It's not hard, I've done it at least 12 times fighting an intake leak! |