| Author | Message | ||

Bluzm2 |

Josh, As I mentioned a while back, I ordered my 1k springs on a Monday afternoon, they were waiting for me when I got home from work on Thursday. Traxxion definately gets the nod for all future projects. The included instructions for install and spacer cutting were very clear. All instructions were also available online. Brad | ||

Deep11sh |

hi all has anyone fited a progresive spring to a stock showa shock at home ,ore is it a job for the HD shop ie trick tools etc thanks | ||

Henrik |

Swapping springs is fairly easy as long as you can get the weight off the front end. Just follow the manual. I would however suggest looking at getting a straight spring rate that is correct for you rather than using progressive springs. Henrik | ||

Josh_ |

RaceTech update. So I email an address that may go to the owner (who knows who reads it) and get no direct response. Yet low and behold the next day I get called with a tracking number (first time in the 2months that they have initiated contact). I call back to verify the # and find out that something I alluded to in the email (that has been wrong for god knows how long) has suddenly been fixed. Maybe someone did read my email. 'course then the forks arrive and I realize that despite all the emails, calls, letters sent with the parts etc etc ... they still never measured my old springs. Everyone I talked to there each time we spoke assured me it would be done. Nope. But they did (this time) manage to stick large "Race Tech" stickers on my forks. | ||

Mikej |

Ahhhh, perhaps they were waiting for the print shop to finish a new batch of those stickers.  But preferably stickers should be placed in the packing and left to the owner to stick them where they please. | ||

Wman |

Question for anyone up on recalls, Picked up new isolator bolts from dealership(AA1006.9FZ). They are not the button head torx that are on my 2001, they are high profile and use allen key. Did they sell me the wrong ones? | ||

Hootowl |

The hex bolts weren't exactly recalled, they just went away with the 2001 isolator kit. Since you have an '01 and I have to guess that you ordered '01 bolts, they did indeed give you the wrong ones. | ||

Wman |

Hootowl Is there any type of safety issue with using these bolts? Did just switch suppliers? | ||

Fnrage |

Has anyone cross referenced the grease seals for the swing arm to another (automotive) number. All 3 of my local dealers ar telling me $6.00 a piece and a week to get them. I'll pay and wait if I have to but if I can get to a local auto store with a cross referenced number that would be cool. Thanks in advance. | ||

Bluzm2 |

Wman, If memory serves, from an article in Battle2win, the bolt lengths are different. I'll see if I can find the article. Have to be tomorrow though... Brad | ||

Anonymous |

Wman, You need to get the right bolts. Using the longer bolt heads will let it hit the rubber portion of the isolator when it flexes and will cause it to tear prematurely. | ||

Lornce |

Anyone know the part number for fork seals for WP forks on a '96 S1? cheers, Lornce | ||

Hootowl |

Yeah, what Anony said. The short bolt head makes it less likely that the rubber will hit the head and tear. It was a design change, not a manufacturer change, though it could be different. I elected to use the hex bolts myself simply because I hate Torkx heads. I haven't noticed any marks on the rubber indicating any rubbing taking place, but I suppose that doesn't mean much. If they go, they go. At least I'll be able to get the bolts out. | ||

Wman |

Thanks for the info guys. I also don't like torx but I probably will order a set. | ||

Loki |

looking for some extra info concerning stock WP shock spring rates. The good stuff like the rates that were installed by model(S2,S1,S1W,M2,S3)from the factory. Thank You  | ||

Ara |

Has anybody had any problem with the rear axle slipping on the swingarm and getting the rear wheel and belt out of alignment? I do, and I've never had this problem before with previous bikes. Is the rear axle torque spec too low, or is there some kind of magic Buell trick that I don't know about? | ||

Josh_ |

While we're on the subject, what size wrench/socket do I need to use on the axle nut on my 98 S1? Anyone? Anyone? | ||

Ara |

Josh, I'll check my '97 S3 and tell you tomorrow. It's probably the same. They're big, and the nut is the same size as the head of the axel. | ||

Blake |

Ara, The only direction the rear axle can slip is rear-ward, right? The adjuster blocks hold it from slipping forward. As acceleration would tend to pull the axle forward, it must be braking action/deceleration that is causing your axle to slip rearwards. I cannot imagine how an axle could slip with 70 FT*LBs of torque resulting in over 4,000 pounds of bolt/axle preload. The only thing I can imagine is that you may have gotten some grease on the faying/mating surfaces where you noticed the slippage, a big no-no. The axle connection is a slip critical bolted joint. Any lubricant between the swingarm and the wheel spacers, or between the washers and swingarm would significantly reduce the ability of the friction joint to keep the axle from slipping rearward. I'd recommend cleaning the faying surfaces of all parts (bolt head/nut/spacers/washers/swingarm) that are part of the axle/swingarm bolted joint. Then I'd retorqe the axle nut to 70 FT*LBs. | ||

Mikej |

Blake, Click his profile, the older Buells can slide foreward as the adjusters are on the rear side of the axle. Unless I'm wrong.  | ||

Blake |

Mike, Look at my profile, I ride one of those "older Buells".  Adjuster holds axle captive. Stud is threaded into adjuster. Stud protrudes through swingarm end-cap. Nut tightened on stud/end-cap prevents stud and thus adjuster and thus axle from moving forward. You must be suffering from a bout of mechanical dyslexia today. Adjuster holds axle captive. Stud is threaded into adjuster. Stud protrudes through swingarm end-cap. Nut tightened on stud/end-cap prevents stud and thus adjuster and thus axle from moving forward. You must be suffering from a bout of mechanical dyslexia today.  | ||

Mikej |

Nah, just computer crashitis downtimeanoyance murkyweatheroutside blurryeyed typical day in the salt mines. Plus I haven't had to even remove or adjust anything on the back of the S2 so I never really looked at it that close yet. Just saw the screw/bolt sticking out and assumed the wrong conclusion. 67 more minutes and I can go home. tick tick tick tick tick tock.  Oh I also use a right handed mouse with my left hand. Messes everyone up but me.  | ||

Blake |

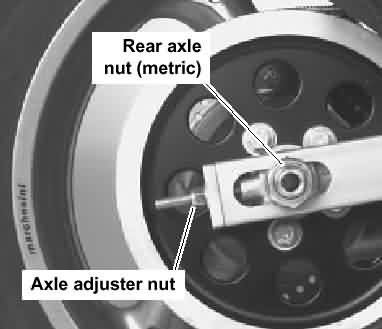

Here's a pic...  | ||

Blake |

Mike, Let me get this straight... You are contending that you are not messed up?  | ||

Josh_ |

So can we calculate from that pic the size of the nut so I can go buy a wrench?? | ||

Ara |

Gents, thanks very much for taking an interest! The left side of the axel does move rearward just a touch. It can't be due to heavy breaking because I simply do not ride aggressively. I think the motor does it by pulling on the drive pully. The pull of the belt wants to shorten the distance between the two pulleys, but the adjusters won't allow forward motion of the rear axle. But reward motion of the left side of the axel does marginally reduce the distance between the pulleys due to the axel/swingarm/rear pulley geometry. That's my theory, anyway. Does it make any sense at all??? And how do I stop it? You can bet that it's going to get a liberal dose of brake cleaner when I get home tonight. Good suggestion, Blake!!! | ||

Josh_ |

36mm | ||

Mikej |

I can neither confirm nor deny the fact of whatever is under discussion.  Josh, (risking another mechanical comment) I have a huge socket that I used to use on a VW Beetle mainshaft pulley. I forget the metric size.  ) comes to mind for some reason but don't buy a socket based on that. The specific size has come up in the tools section and in the wheel section of the KV several times. (maybe at least this will prompt someone to prove me wrong and therefore get Josh his info.) ) comes to mind for some reason but don't buy a socket based on that. The specific size has come up in the tools section and in the wheel section of the KV several times. (maybe at least this will prompt someone to prove me wrong and therefore get Josh his info.)  edited by mikej on June 05, 2003 | ||

Josh_ |

MikeJ, thanks to Cruztools I know it's 36mm  Thanks my search techniques must be off as I did not find it with a search | ||

Blake |

Josh, I've always used a 15" crescent wrench (adjustable spanner). You'll need two or you can use a pipe wrench to backup the bolt head. The wrench size that would work would be a 36mm, but a 1-7/16" would do the job okay too. I recommend the crescent wrench approach.  |