| Author | Message | ||

Hippyjoe |

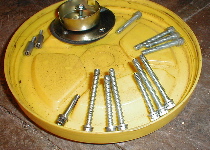

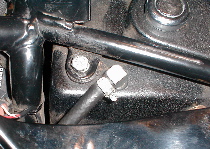

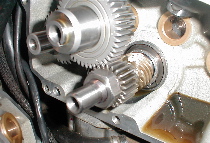

'00 M2, 11k miles, upgrading the OPD gear and the cams while I'm in there. I wanted to "interrupt" as little as possible with this job. I had intended to leave the front rocker box alone, but couldn't get the cams in that way... so, I had to pull: 1. Cam cover, timer cover/rotor 2. Both rocker boxes 3. Fuel tank and seat 4. Horn and coil AIRC that's it. I didn't have to pull the carb, pushrod tubes, or tappets. I did elect to replace the factory pushrods with Andrews fixed-length alloy, to lighten up the valvetrain a little. They slipped in through the top with the rocker boxes off. Here is a link to part #'s. Cams were SE bolt-in. Pushrods were '91-03 Evo XL, Andrews #292025. First, getting the cam cover off: There are 3 different length bolts. You can either sort them by length, or mark one and keep them in order, following the torque sequence numbers assigned in the SM.  I did the latter, then bumped the tray and lost the order. It was just as easy to install by different length, as there are only 3 AIRC. Getting the cover off is straightforward by the SM, with the exception of a vent line that holds it on, which wasn't mentioned. A stainless factory crimped clamp holds it on at the cover end, so I removed the other end at the oil tank, and fed it through with one hand while pulling the cover out with the other.  I let the cover hang in place by the vent line, keeping it taught enough so that the ignition wires weren't supporting any of the weight of the cam cover. Here is a pic of the pinion gear tool in action.  Very easy to use, the nut came right off, RH threads AIRC. Although I had to use a small puller to get the gear off, and it's not a press fit. A battery terminal puller is too small, you need a real gear puller. Made sure to clean up the shaft and nut with brake cleaner prior to reassembly w/ red loctite. Here is the new, bronze OPD gear.  I also went with a new Woodruff key under the gear. The pinion gear is held in place with the same key, AIRC, and it all snugs down tight together. Rest of the process was straightforward. Random notes, from memory: 1. I used a fair amount of grease on most of the rocker box gaskets, to hold them in place while reassembling the boxes. Also a little grease on the case side of the cam cover gasket. 2. To get the rear exhaust pushrod in, I used a medium-sized screwdriver wrapped in a rag between the head and frame, pried, and the oiled pushrod slipped right in. 3. The cam instructions said I could leave the front lower rocker box in place, just pull 2 rocker arm bolts and slide the rocker arms out. By loosening the front isolator and prying the front of the engine down with a breaker bar I was able to remove the rocker arm shafts and arms, allowing the front cams to slip out. However, I couldn't get the shafts back in place with the new cams in, so I had to pull the front lower rocker box after all. 4. After getting it all back together, I had a lifter that was slow to pump up. Researching the archives here, I noticed the '00-up lifters are smaller and prone to failure. So it wouldn't be a bad idea to pull the pushrod tubes and lifters after all, and replace them with aftermarket lifters, collapsible tubes and adjustable pushrods. As long as you're in there. 5. Some people have reported leaks after doing this job. I was extra careful to slide the aforementioned crank vent hose back and forth a few times under the starter to make sure there were no kinks. I was also pretty anal about following the SM torque procedures. I must have gone around the cam cover and rocker boxes 12 times each before I hit final torque values. 6. A big reason I chose the SE bolt-ins is because they are true bolt-ins. No gear binding, no clearance issues, no need to check end play. I did eyeball the relationship between the pinion gear face and #2 cam gear face before removing the original, and compared it to the new #2 gear upon installation. Sure enough, the new gear sat further inboard of the pinion gear, maybe .010-020". Won't ever bind, might make a little more noise. 7. Anti-seize on the exhaust studs, blue loctite on the timer cup screw, no silicone whatsoever anywhere near the engine oil!! The rest of the bolts I installed "dry," figuring that the internal rocker bolts are bathed in oil, and most of the socket head screws were loctited at the factory... steel going into aluminum, best not use much loctite there. I also prefer engine oil to assembly lube for the cams, gears, pushrod ends, rocker arm shafts. Changed the oil after 25 miles. For now it's running fine, no leaks, no excessive noise. 500 miles so far. The valvetrain is a little louder than stock at the rocker arm end, but I no longer have to worry about cam failure. Or OPD gear failure. And the power is much better when getting on the interstate. I don't notice any noise coming from the cam cover. Unless I pull the timer cover and lean next to the ignition, then I hear the cams in there. | ||

Jayvee |

Very nice write-up. I'm interested in this mod too. What's your impression of the powerband now? Did you lose any torque in the low-end of the rpm range? Where does the power increase? How high have you rev'd it so far? | ||

Hippyjoe |

Hey, Jackie. I'll answer your questions if you sell me your yellow tank  My impression is that the powerband moved up about 500 rpms. I don't have a tach, so I'm guessing... I would say that there is a little less low-end "grunt," which I didn't want to happen. However, riding around the city, I don't suffer from any loss of useable torque. The power kicks in just below the sweet spot, maybe 2200 rpm... once it kicks in, it pulls without letting up until I feel the need to shift... probably around 5800. I don't rev it too high... I had to crank it from 60-90 on the interstate, it got there quick and still had a lot left. My rev limiter is set at 6300 and I haven't hit it yet. I think these cams really take advantage of the aftermarket ignition, pipe, and CF intake. I'd say the original M2 cams pull like a tractor... these pull more like a locomotive. | ||

Blake |

Did you remove rocker boxes cam cover first? (Message edited by Blake on August 28, 2006) | ||

Hippyjoe |

Did you remove rocker boxes cam cover first? Blake: I'm pretty sure I pulled the cam cover first, easing it off the cams. I used my thumb to keep #2 in the case bushing, and the rest held fast. The vent line helped, ensuring that the cover was slow to come off. I was testing to see if I could ease the cams out one at a time with only the cam cover removed. I couldn't, so pulled the rocker covers. Next time, I'll know going in and pull the rockers first. And install adjustable pushrods. Although I hope to be good for 100k before having to go in there again... . | ||

Jayvee |

Sorry HJ, but my blue tank is the spare. I like low-end torque, but if I can, I want it all, low to high. I'm pretty sure I don't want to give up any low-end at all though. Maybe I'll just keep my Reactor (Yellow) Tractor as is for now. Maybe I just like the sound of "bolt-in" anything. But it is very nice write-up. (Message edited by jayvee on August 29, 2006) | ||

Blake |

Bad news, potentially. Removing the cam cover first can subject the case-side cam bushings/bearings to problematic stresses. They are not designed to withstand cantelever loading like that, meaning they need the help of the cover-side bushings/bearings to help support the significant load of the spring-loaded valvetrain. I'm sorry to have to be the bearer of bad news. If you are lucky, your engine was rotated to a point where all the valves were closed thus minimizing the spring-loading of the valvetrain on each of the cams. | ||

Hippyjoe |

Jayvee: I was hoping to gain a little torque, or at least not lose any, considering the SE cams added .040 or so to the lift... must be the overlap, it's a lot more aggressive with the SEs. Blake: I had 3 valves totally closed, the other was almost closed, and the lifters were all bled down before I started. Didn't rotate the engine with the cover off, I think I'm fine. It's bushings, not bearings, I think the potential bad news for the bushings is too much spring pressure from hi-lift aftermarket cams, that's a big reason I kept it to stock-spec Lightning cams. Bushings last a long time before needing attention, as long as they're not spun. Anyway the cam lobes run close to the inboard bushings, I don't see a whole lot of cantilever action going on, as long as you're careful. Oh yeah, thanks for reminding me-- one last thing to check before firing the motor up is first, I assembled the gearcase, then rolled the motor over by hand to make sure the cams spun freely with the cover on. Once I got the rocker arms back in, I rolled it over again, just to make sure nothing was binding up in the valvetrain. | ||

Bomber |

it IS possible to pull the cam cover wiht the cams loading the valve -- and to re-install it, too, with bad results all it takes if a HUGE amount of luck (35,000 mile later, no problems) I'll not trust my luck that much again, though -- I'm smarter now than I was then ;-} |