| Author | Message | ||

Normally_aspirated_sucks |

I'm in the process of building a stupidcharger for my M2. I've got everything planned but the actual crank take-off. I have some ideas on how to take the power off the crank, but would like to know if anyone has ideas. It will come out the primary cover where the front bulge is. TTS was designing a unit similar to what I'm doing. I'm trying to keep the engine stock and gradually do a small steps and dynos between to see what is happening. | ||

Tramp |

baby steps, hans. watch that crank bearing bahnfrei, jay | ||

Normally_aspirated_sucks |

Nice to here from you again trampy. The drive pulley will be supported in the gear housing that will be attached to the outside of the primary, so there shouldn't be any side force on the crank. The boost pressure will only be at 2lbs at 2000rpm and 6lbs at 6950rpm. Just enough to get over the inefficiency of a normally aspirated engine. When I can afford a complete engine build up, I'll start raising the boost on the stock engine and wait for the BOOM. Just kidding. The bottom end should hold together easily up to 120hp, 130-140 if pushed. The compression ratio will hold me back on the boost, so, I'm stuck with 6-8 lbs till I get into the top end/pistons. Even at 6lbs my stock engine, except for the race package stuff, should put me in the 100-110hp at the rear wheel range. Cost, under $250, if not cheaper, but a LOT of time. | ||

Reepicheep |

If you want to stay off the crank, what about replacing the primary chain tensioner with a gear and some creative reconstruction of the primary cover? It would protect the crank bearing, give you a lot more flexibility in mounting locations, and even let you fiddle with gear ratios for the supercharger. | ||

Reepicheep |

Man. Now you got me thinking (relative to the XB's). Bolt on primary cover replacement, with a drive shaft that goes up to the hole in the frame, where a fan assembly is inserted and sealed into the frame air tunnel attached to the other end of the shaft. From there it goes into the factory sealed airbox assembly. Simple, compact, braindead easy to install, and not that intrusive. | ||

Tramp |

a third pulley in that loop would effect detrimental drag and harmony issues. if you want to 'saty off the crank', try a good halfway house, or maybe just cold turkey with plenty of coffee. | ||

Normally_aspirated_sucks |

Right now I plan on going off the crank. It'll be a plate with pins that has a hollow shaft. Take the nut off the primary gear slide plate/shaft on, put original nut back on through inside of shaft. Primary will be flattened and opened up to allow shaft and seal. I'll have plenty of room for gear changes in the arm that goes from the primary to the supercharger. I'm already stepping it up something like 17:1. The impeller will be spinning at about 120,000rpm when the engine is at 7,000rpm. Went and looked at the cover I'm going to modify, I don't think the chain tensioner idea will work, I'd have to get REAL creative for that one. Then I'd run into either having the chain to tight or the supercharger slipping. Though, now I've got an idea about a roller tensioner instead of that flat thing. HMMMM. | ||

Tramp |

that sounds best. instead of just a seal in the primary orifice you could mock up an easy-to-remove carrier bearing, as well. | ||

Normally_aspirated_sucks |

Reepicheep, Check out Hillbilly motors, they have a supercharger kit for a XB. | ||

Normally_aspirated_sucks |

Tramp, I'm trying to drive it so the only force the crank feels is the torsional spinning one. They rest of the drive unit will be kind of independent. | ||

Tramp |

so it'll be suspended at a point outside the case, right? | ||

Normally_aspirated_sucks |

No, The shaft/plate will only go as far as the seal at the case. The drive shaft unit will slide into the primary bolted shaft, which will be splined, and bolt to the 4 reinforcements, which will be drilled and tapped, on the primary cover. Similar to a cars engine/transmission. This way the oil in the primary stays where it is and the drive lubricant stays where it is. Also, it makes it easier to remove. | ||

Normally_aspirated_sucks |

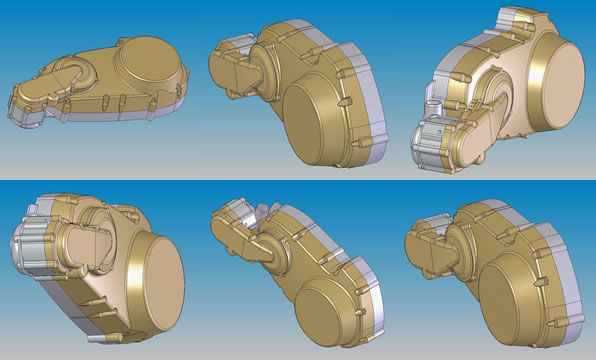

This is what TTS's unit would have looked like for the XB. Mine is real similar.  | ||

Oldog |

N_A_S on the special primary drive there was some info in the KV on one tentioner to avoid http://www.badweatherbikers.com/cgibin/discus/show.cgi?tpc=3842&post=68758#POST6 8758 are you for real on the 120,000 rpm? most common power and air tools are maxing at maybe 30K rpm will this be a racing application? | ||

Normally_aspirated_sucks |

That's for real on the RPMs. If I go to a bigger compressor I could slow it down, but space is limited. Look what a turbo spins at, 40,000-210,000. At first, it will be just to get over the volumetric inefficiency of a normally aspirated motor, stock engine is estimated at 65% at sea level. And you'll never come close to 100% at any RPM above idle. After a motor build it will be there for me to be stupid, hence the first line of this thread, STUPIDCHARGING. | ||

Normally_aspirated_sucks |

Oldog, The tensioner I'm think of now is a roller not a plastic slider. I have a 02', it already has the updated tensioner. | ||

Normally_aspirated_sucks |

http://www.hillbilly-motors.com/html/rotrex_supercharger.html   | ||

Firemanjim |

Hans,are you using the same style supercharger as the boys from here-http://www.calisuperbikes.com/ Interesting stuff,keep us informed.Always looking for more power for my Buell for B'ville. | ||

Artflame |

N A S any pics of your setup? that setup was for sale in england by tts-performance for tubers but i think they don't make them anymore . so i went for an aerocharger instead (Message edited by artflame on June 17, 2005) | ||

Normally_aspirated_sucks |

Firemanjim, I am using a centrifugal, but not a Rotrex, which is the brand they use. Artflame, When I contacted TTS, toward the end of them posting it on their web site, they said it was only for the XBs and the design phase never went into production and they weren't planning on a one for the tube frames. No pics yet. I thought about a turbo, but wanted to go a different way. Did you get the kit with the intercooler or without? Same compression ratio? How do you like it? (Message edited by normally_aspirated_sucks on June 17, 2005) | ||

Craigster |

I am curious as to how you will attach the extension shaft to the existing crank. Do you have any drawings on that yet? How about a magnetic clutch assy between the drive and supercharger. It would allow for slip without having to wory about using a ribbed belt as the 'clutch assy' in the whole deal. I've been kicking that idea around some and looking at some of the dry pumps out in the back of our factory. They use such an arrangement as they need to stlip at start up and when operating in atmosphere (very high compression ratio.....1000s:1!!!!). | ||

Normally_aspirated_sucks |

I don't want it to slip, you would have lag, like a turbo. I like the idea, though, I don't ever remember seeing a unit small enough for what I'm doing that would have enough holding force. That's a lot of interference with the charging system also, lines of flux and all that. Not to mention probably turning the crank into a magnet that attracts the metal in the oil. | ||

Mmmi_grad |

Is turbo really worth having on a buell? I mean the cost and maint compared to custom and optimized engine parts seems to to me that turbo on a buell = more oooooh and ahhhhhhh than ok 1) i have reached a horse power achievement that cant be matched easy by anyone else. 2) I can still control the bike while reaching the turbo made results, in addition to any other need that maybe necessary with such a thing hanging off the side. { im suddenly thinking back to all the sportbikes ive seen with turbo and the big willie bars hanging off the back  ah yes that would be cool } ah yes that would be cool } Now before you start thinking anything negative, i can assure you that i dont know anything about turbo on a sportster or a buell. I think its a cool thing to have and all of that stuff. I just write this cause of my lack of knowledge about turbo and the sportster [buell] motor and an opportunity to think outloud  Good luck on the project! Oh and while i am asking about limits I may as well through in a story. About 17 years ago I got a some new people moved in down the block from me and I had a 57 panhead that was new to me. The guy down the block had a 76 sportster with evader mags thats was stock and cool but had a blown top end. That year while going through my topend I helped him rebuild his bike. Basically he was in trouble. Not only was his top end wore out but what put the bike down was a exploded piston !!!! After piston fell apart... i think it was the front the conncting rod managed to awol and bend 90 degrees while going for a trip down into the case!!!!!!! When i first saw it I was instantly amazed that the rod didnt blow out the bottom of the case. Actually the case was fine it was given to the dealer to get the crank set up and then we did the rest. I wonder if todays sportster casting would survive such a thing sometimes  (Message edited by mmmi_grad on June 17, 2005) Ok last edit:  I am also reminded about how a local bike shop owner tried to help someone with thier softtail evo. The guy had the stag 1 screaming eagle kit and for somereason decided to try some even bigger pistons. Pistons may have been custom axtell or harley I cant remember. The guy that owns the shop is an old HD mechanic and dealer manager. He checked the set up and it was fine. After firing the thing up and doing some testing either one or both pistons blew up. Explanation was that the motor just could not handle the bigger pistons. $$$$$$$$$$$ I am also reminded about how a local bike shop owner tried to help someone with thier softtail evo. The guy had the stag 1 screaming eagle kit and for somereason decided to try some even bigger pistons. Pistons may have been custom axtell or harley I cant remember. The guy that owns the shop is an old HD mechanic and dealer manager. He checked the set up and it was fine. After firing the thing up and doing some testing either one or both pistons blew up. Explanation was that the motor just could not handle the bigger pistons. $$$$$$$$$$$ (Message edited by mmmi_grad on June 17, 2005) | ||

Bandm |

Could it be driven off the cam gears like the old style generator drive? The camchest still have the space for an extra gear or two | ||

Craigster |

NAS, I guess I should have put a bigger gap between paragraphs. I was thinking of placing a brake at the end of the belt (or gear) drive to the super charger. Not suggesting using a clutch that slips enough for lag. Thinking of when you snap the throttle open and closed the extra load on the drive system usually hammers the parts to death. A small hysteresis brake might do. Permanent magnet type. No electrical excitation required. A lot of them contain a hysteresis disk directly attached to the hub that passes through the clutch. Two circular multi- pole magnets are solidly attached internally within the unit. The magnets face each other with the hysteresis disk between them. There is an air gap between the magnets and the hysteresis disk. The hysteresis disk can turn without any friction. The opposing circular magnets set up magnetic flux, which causes drag on the hysteresis disk, which in turn, causes drag to the hollow hub in the unit. To increase or decrease the amount of output drag, one of the magnetic disks can be moved through a 90 deg range. As the magnet poles are aligned north to south with each other, they produce the maximum amount of drag on the hysteresis disk. As the poles are rotated from a north to south position, the lines of flux pass straight through the hysteresis material, reducing the amount of drag on the disk. The idea would be to set it for the maximum drive force of the blower. Anything exceeding that would cause the clutch to slip. Hence snapping the throttle shut would not subject the crank and drive system to the inertial forces of the blower. Just a crazy idea I've had for fixing the hammer effect on the supercharger..... | ||

Koz5150 |

Just when I feel good about my mechanical ability and knowledge I read a thread like this and come to the conclusion, "I don't know nuttin!" | ||

Oldog |

there was a turbo sporty at CCHD here in Wilmington, As I have it the stock crank is prone to let go at rwhp in excess of 140 says the SM. I was told that the bike broke a rod in the dyno room, in that hp range, This was second hand Ymmv Good Luck post picks | ||

Firemanjim |

Stock rods are prone to give up the ghost in those HP ranges,crank is actually good for more than that,next in line for failure is the crankcase.When Brian Nallin was dynoing my bike for Bonneville he decided to let off the throttle at 177 HP as he wanted the motor to last til Bonneville.He was worried about crankcase spitting the crankshaft out the bottom.After removing the turbo from the bike I had a stock rod let loose one day on a cruise.Broke right in the middle of the rod and proceeded to make junk of my cases. | ||

Craigster |

Wow, that sux Jim. To have made it that far and have a failure under almost zero load must be heart breaking (no pun intended). You ran stock rods to 177 hp? Were they reworked i.e. peened? Have you ever had experience with shot peened stock rods? I was thinking of sending out some stockers w/some stuff from work (Shhh! Don't tell anyone.) Not sure how much stronger that will make them unless I were to actually test them 'til failure. Also, what RPM were you spinning that LSR motor up to? | ||

Normally_aspirated_sucks |

The problem with over banging the rods with hp and then going back to normally aspirated is you lose the cushion factor. With boost there is always pressure on the piston so you don't get the SLAP at the bottom as it gets to BDC and starts heading back up. Though the way I'm going to run the blow off will take care of this better. Might be redundant, but a safer design. Craigster, Now I understand what you are talking about. After reading your original post, I started thinking of running a electromagnetic clutch to a pressure sensor. When I let off the throttle hard and the pressure goes through the roof, let the clutch disengage so the engine slowing down isn't still trying to slam the air in. |