| Author |

Message |

Blake

| | Posted on Sunday, January 23, 2005 - 04:13 pm: |

|

Slick 50 may help with lubrication of the engine; though I very much doubt it does except possible in cases of metal to metal contact, which should rarely if ever occur. What I do know is that Slick50 reacts in the combustion chamber to produce some very acidic compounds that within a year will have your exhaust tract components falling apart. Don't ask how I know.  But this is not just my experience, it is documented online by experts and has been the experience of most everyone who has ever used the stuff. If you are lucky the FFC won't harm your engine. No way it helps it. It is pure voodoo hokum. But this is not just my experience, it is documented online by experts and has been the experience of most everyone who has ever used the stuff. If you are lucky the FFC won't harm your engine. No way it helps it. It is pure voodoo hokum. |

Starter

| | Posted on Wednesday, January 26, 2005 - 11:24 pm: |

|

A note on Slick 50, I found some of the literature from way back and talked to a friend in the engine recon business. Whilst he was young and dumb back those days and doing his apprenticeship he said that they specifically asked every customer if they had used Slick 50 in the engines they wanted rebuilt. If the answer was "Yes" they told them to take it elsewhere, "No" and they would accept it but have a test done on it to confirm the answer. He said under no circumstances would they let their machinery anywhere near the treated metal. |

Starter

| | Posted on Wednesday, January 26, 2005 - 11:32 pm: |

|

Funny we should be talking of these products, there is a box of trials that some guy wanted us to put in our $1Mil machines called Centron II. This stuff puts a positive charge on the engine and then the negative charged protection fluid is locked into place. I wonder why we were sent a letter from legal reps explaining to us why our warranty contract was going to be torn up if we used it. |

Thunderbox

| | Posted on Thursday, January 27, 2005 - 08:20 am: |

|

I use a product called Power Up. We have been using it in all our fleet (police) about 160 vehicles for over 10 years now. We did oil analysis and long term testing. I actually tried to prove it didn't work. That was the first thing I wanted to do. It works beyond a doubt. We use it in our trannys, PS, differentials and engines. I use it in my Buell and have had no problems. I have on occasion gotten over 74 MPG (Thats imperial gallons equal to 5 US quarts)Go to this site to see the information.

http://www.maryngroup.com |

Blake

| | Posted on Thursday, January 27, 2005 - 03:15 pm: |

|

I once got 76 mpg two tank fulls in a row on my then stock '97 Cyclone. That was up in the Colorado and New Mexiso mountains cruising easy on the way back home to Texas.

What about the Power Up convinced you that it works "beyond a doubt."

Hmmmm, upon a quick review, I note the following from...

http://www.maryngroup.com/Product_Information/Power_Up/NNL690.htm#technical%20da ta

| Temperature | Viscosity | Equiv SAE WT Engine Oil | | 40oC (104oF) | 70 cSt | 20 WT | | 100oC (212oF) | 9 cSt | 20 WT |

At 100oC (212oF) our Buell 20W50 SAE engine grade oil should provide a viscosity of at least 15 cSt. Reducing the viscosity of engine oil will always improve fuel mileage assuming of course that lubricatn film thickness does not diminish to a point where metal to metal contact occurs. Not sure what Power Up does to the ability of the oil to protect the engine though.

Dave, I think your initial skeptical view is probably the correct one. There simply is no free lunch when it comes to engine lubrication, and if there were some new lubricant technology that significantly improves engine efficiency (fuel efficiency), the automotive manufacturers would be killing each other to get to it.

Anyway, my mind is open yet skeptical. What exactly convinced you that the stuff works, and what exactly does it do? |

Thunderbox

| | Posted on Thursday, January 27, 2005 - 03:50 pm: |

|

But just so you know where I'm coming from. My own engine oil tests proved it lowered wear particles in our oil by an average of 21%. Our transmission repairs went down by 57%. I went as far as using 2 vehicle classes some that were outside in the winter and some that were inside in the winter. The outside ones had the same wear as the inside ones had but the outside vehicles had Powerup in them. When I added the inside ones to the test the wear particles went down on average 21%. I did a lot of testing on this product to prove it didn't work. I personally tested vehicles that had travelled 6 million kilometers during testing. Everything I did proved the opposite. So unless you want to go and do the expensive oil testing and take a year using vehicles that travel 3 million kilometers a year then you either believe it or you don't. In the 13 years I have been running this Police Garage we have never had an engine fail because of wear or lack of lubricant. Thats 39 million kilometers of driving. Not bad IMHO.

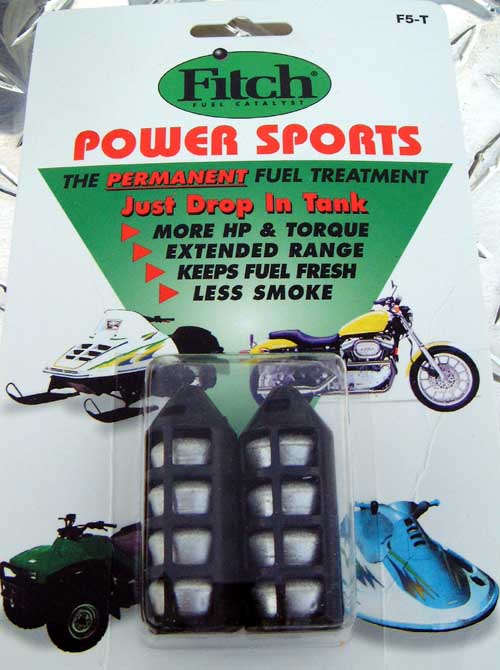

I also did testing on a Fitch mecho when I was in the armed forces. It didn't make a bit of difference. We used generator sets with load banks and not 1 Iota of difference was shown. But really I could care less if anyone believes me or not about powerup. I don't have a penny invested in it so use it or don't.

To say there is no better oil or additive than what they are using now is bull. The oil companies have been saying that for years and about each couple of years they come out with a better oil. Only when the manufacturers tell them they have to have a better something or other. Remember SA then SB, then SC then SD and so on Now we are up to SL and it won't be long and it will be SS. I say follow the money if you want the real story. The manufacturers will pinch a penny if it can save them anything. Why pay for better oil if they don't have a reason to make someone develop it.

(Message edited by thunderbox on January 27, 2005) |

Blake

| | Posted on Thursday, January 27, 2005 - 04:36 pm: |

|

How much of the fleet that you monitored did you leave untreated, without the Power Up? |

Thunderbox

| | Posted on Thursday, January 27, 2005 - 05:12 pm: |

|

I started with about a quarter of the 160 vehicles and by the time I was done it was just less than half. I couldn't have done more extensive testing. I stopped when the results were so darn consistent. We drive our Expeditions 325000kms or about 200000 miles. Other than a broken valve spring and a set of valve guide seals no engine problems. As a note, we put hour metres on them and they were just over 12000 hrs. This is diesel rebuild hours. We sent them to auction and they still weren't burning any oil. 100% city driving also. Weather down to -35 often and parked outside not plugged in. |

Thunderbox

| | Posted on Thursday, January 27, 2005 - 05:15 pm: |

|

Sorry that really doesnt answer the question properly. We had 3/4 of the fleet untreated at first and I added vehicles as the testing went. When we were finished testing more than half the fleet were untreated. This additive is added to each oil change and is not an additive that you put in once every 25000 or so. One once per litre or US quart every oil change. |

Blake

| | Posted on Thursday, January 27, 2005 - 06:45 pm: |

|

I'm wondering how many untreated vehicles you monitored simultaneously with the treated ones. Any? |

Thunderbox

| | Posted on Friday, January 28, 2005 - 10:08 am: |

|

For every vehicle that was treated I monitered an untreated one also. Any more questions let me know. |

Blake

| | Posted on Friday, January 28, 2005 - 01:24 pm: |

|

Are you kidding me, I love this stuff! I'll wear you out with questions trying to understand your testing and conclusions. Please note that my interest is in no way personal or meant to impugn you or your tests. I am interested solely in the scientific validation of your conclusions. The evaluation/validation of test results is a field with which I am intimately familiar at the most rigorous professional level. So if I sound like a total geek weenie, please forgive me.

I certainly never meant to imply that "there is no better oil or additive than what they are using now". And contrary to your claim, I've never ever heard such a claim made by anyone, let alone the oil companies who invest hordes of their money into R&D to do just the opposite, to come up with a better lubricant.

I think my basic logic is valid and awfully tough to refute, that if there exists an additive that significantly improves engine efficiency while maintaining let alone improving the integrity of engine lubricant, the manufacturers of automobiles would be killing each other to get it. Why? Besides the advantage of offering a more fuel efficient product which would be more attractive to the consumer, even a small percentage improvement to fuel efficiency would be of great benefit to automobile manufacturers who must meet strict fleetwide fuel efficiency performance requirments or else pay the dreaded gas guzzler tax.

So let's take a look at your testing and data and analyze it and see if we can scientifically confirm/validate your conclusions.

What were the sample sizes (how many vehicles were monitored) for treated and untreated?

Through how many engine lubricant change cycles was the testing performed and data recorded? If this varied among test samples, what were the least and greatest number of cycles.

What average change in the wear rate if any did you see for the untreated vehicles?

What were the maximum and minimum wear particle rates for untreated and treated samples?

What were the single maximum and minimum changes in wear particle rates for untreated and treated samples over the course of one oil change and over the course of the entire testing (looking for 8 data points here, 4 maximums and 4 minimums)?

Were the untreated vehicles mechanically identical to the treated ones (same year, model, engine mileage, operational missions)?

What engine lubricant did the untreated and treated vehicles utilize?

What do you mean by "inside" versus "outside" vehicles?

Did you monitor fuel efficiency, and if so what conclusions if any were you able to support from your data?

Did you evaluate the statistical integrity of your data? For instance, you report a 21% average improvement/decrease in wear particles. Was that for engine lubricant only? Such an average value is meaningful only in context of proper statistical analysis and a high confidence that no factors other than the presence or absence of the Power Up significantly influenced the data. Barring some systemic difference between the operation/testing of treated versus untreated vehicles, the larger the sample sizes, the less likely outside factors will skew the results .

The statistical analysis of test data involves sample sizes, and requires complete and accurate characterization of all pertinent parameters, especially the consistency of results across the entire population of samples. You may be familiar with the terms "variance" or "standard deviation." If so, did you evaluate those characteristics of your test data? If you did, what did you find?

Some more factors to consider...

1. Configuration of each test vehicle at start of test (make, model, mileage, operational mission).

2. Test interval information (mileage, type of base lubricant, lubricant used/consumed/added, fuel consumption, mission, operational notes, wear particle composition and quantity).

If you have this kind of data in a convenient form like a spreadsheet, the analysis would be greatly facilitated and I'd be willing to do it. On account of I am one sick puppy and I dig this kind of stuff.  |

|

»

Dyno Test Results - Fitch Fuel Catalyst

»

Dyno Test Results - Fitch Fuel Catalyst

»

Dyno Test Results - Fitch Fuel Catalyst

»

Dyno Test Results - Fitch Fuel Catalyst